Town multi-element organic waste for preparing biogas and method for preparing biogas from same

A technology of organic waste and vegetable waste, applied in the direction of waste fuel, biological sludge treatment, fermentation, etc., can solve the problems of incomplete digestion of fermentation materials, low biogas production, unstable operation, etc., and achieve significant economic and environmental ecology benefit, improve degradation ability, and reduce investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

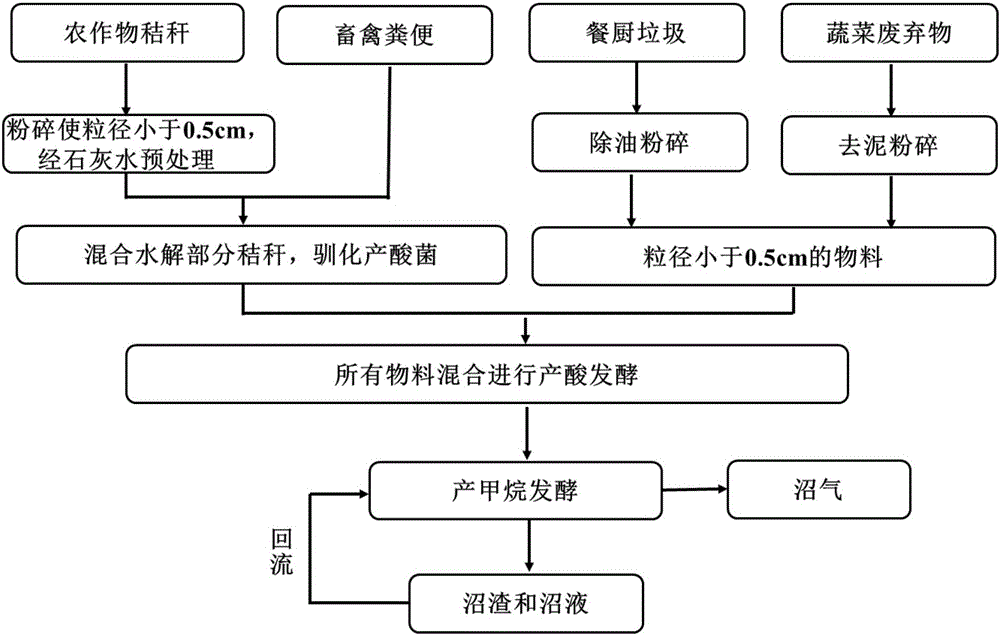

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: a kind of multi-element organic waste from villages and towns for preparing biogas in this embodiment, it is composed of 10-20 parts of crop straw, 10-20 parts of kitchen waste, and 20-40 parts of livestock and poultry manure in parts by weight. 15-20 servings of vegetable waste.

specific Embodiment approach 2

[0017] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that it consists of 15-20 parts by weight of crop straw, 15-20 parts of kitchen waste, 30-40 parts of livestock and poultry manure and vegetable waste 15-20 servings are made. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment one is that it is composed of 10-15 parts by weight of crop straw, 10-15 parts of kitchen waste, 20-30 parts of livestock and poultry manure and vegetable waste 15-20 servings are made. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com