Preparation method and products of organic metal complex and aluminum oxide compound

A technology of organometallic and inorganic oxides, applied in the field of preparation of organometallic complexes and alumina complexes, can solve problems such as low surface active points, battery structure damage, failure, etc., achieve improved atomic structure composition, and simple preparation methods Practical, outstanding effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An organometallic complex consisting of bis(2-methyl-8-hydroxyquinoline-N1,O8)-(1,1'-biphenyl-4-hydroxyl)aluminum (CAS146162-54-1, molecular formula C 32 h 25 AlN 2 o 3 ) and 8-hydroxyquinoline aluminum (C 27 h 18 AlN 3 o 3 ) composition, the mixing weight ratio of the two (2-methyl-8-hydroxyquinoline-N1, O8)-(1,1'-biphenyl-4-hydroxyl) aluminum and 8-hydroxyquinoline aluminum is 2:8.

[0036] The preparation method of above-mentioned organometallic complex, concrete steps are as follows:

[0037] (1) Weigh bis(2-methyl-8-hydroxyquinoline-N1,O8)-(1,1'-biphenyl-4-hydroxy)aluminum and 8-hydroxyquinoline aluminum as raw materials according to the recipe ;

[0038] (2) Mix the weighed bis(2-methyl-8-hydroxyquinoline-N1,O8)-(1,1'-biphenyl-4-hydroxy)aluminum with 8-hydroxyquinoline aluminum, Instantly.

Embodiment 2

[0040] An organometallic complex consisting of bis(2-methyl-8-hydroxyquinoline-N1,O8)-(1,1'-biphenyl-4-hydroxyl)aluminum (CAS146162-54-1, molecular formula C 32 h 25 AlN 2 o 3 ) and 8-hydroxyquinoline aluminum (C 27 h 18 AlN 3 o 3 ) composition, the mixing weight ratio of the two (2-methyl-8-hydroxyquinoline-N1, O8)-(1,1'-biphenyl-4-hydroxyl) aluminum and 8-hydroxyquinoline aluminum is 5:5.

[0041] The preparation method of above-mentioned organometallic complex, concrete steps are as follows:

[0042](1) Weigh bis(2-methyl-8-hydroxyquinoline-N1,O8)-(1,1'-biphenyl-4-hydroxy)aluminum and 8-hydroxyquinoline aluminum as raw materials according to the recipe ;

[0043] (2) Mix the weighed bis(2-methyl-8-hydroxyquinoline-N1,O8)-(1,1'-biphenyl-4-hydroxy)aluminum with 8-hydroxyquinoline aluminum, Instantly.

Embodiment 3

[0045] An organometallic complex consisting of bis(2-methyl-8-hydroxyquinoline-N1,O8)-(1,1'-biphenyl-4-hydroxyl)aluminum (CAS146162-54-1, molecular formula C 32 h 25 AlN 2 o 3 ) and 8-hydroxyquinoline aluminum (C 27 h 18 AlN 3 o 3 ) composition, the mixing weight ratio of the two (2-methyl-8-hydroxyquinoline-N1, O8)-(1,1'-biphenyl-4-hydroxyl) aluminum and 8-hydroxyquinoline aluminum is 2:5.

[0046] The preparation method of above-mentioned organometallic complex, concrete steps are as follows:

[0047] (1) Weigh bis(2-methyl-8-hydroxyquinoline-N1,O8)-(1,1'-biphenyl-4-hydroxy)aluminum and 8-hydroxyquinoline aluminum as raw materials according to the recipe ;

[0048] (2) Mix the weighed bis(2-methyl-8-hydroxyquinoline-N1,O8)-(1,1'-biphenyl-4-hydroxy)aluminum with 8-hydroxyquinoline aluminum, Instantly.

PUM

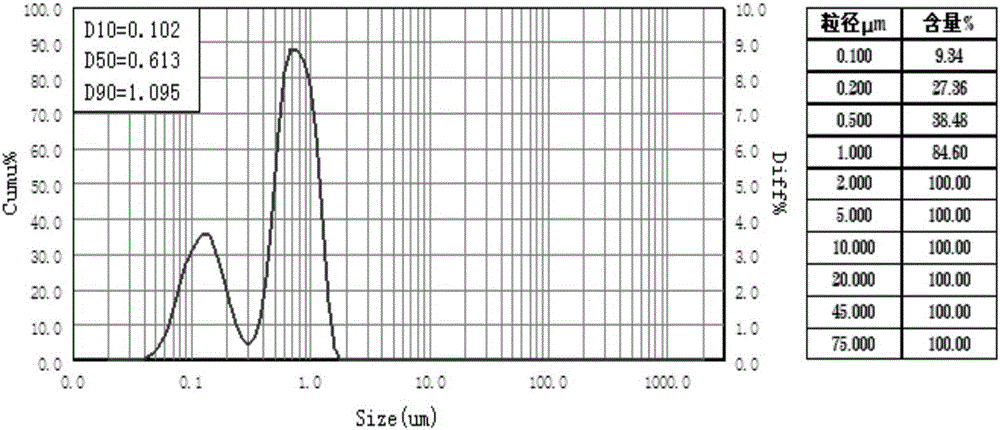

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com