Overall structure of superhard material cutting machine

A technology of superhard materials and overall structure, applied in stone processing tools, stone processing equipment, fine working devices, etc., can solve the problems of limited volume and weight of superhard materials, easy deformation of diamond spools, poor stability, etc., and achieve good results The effect of market promotion value, high cutting efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

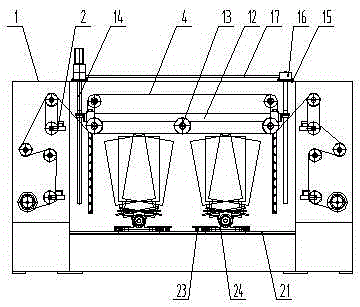

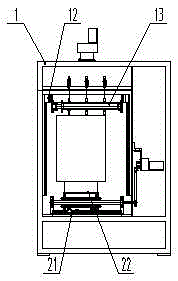

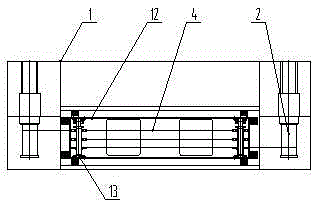

[0019] Such as figure 1 , 2 , 3, 4, and 5, the present invention includes a frame 1, a pair of discharge line guide system 2, a multi-axis binding mobile system, a group of cutting lines 4 and a pair of special workbenches, a pair of discharge line guide system 2 They are respectively symmetrically installed on both sides of the frame 1, the track of the multi-axis binding mobile system is fixedly installed on the frame 1, the independent V-wheel system is installed on the multi-axis binding mobile system, and a group of cutting lines 4 are respectively wound on a For the discharge wire guide system 2 and a group of independent V-wheel systems, a pair of special workbenches are installed side by side on the frame 1 respectively, and are located under the independent V-wheel system.

[0020] The multi-axis binding mobile system is composed of a lifting guide rail mechanism, a moving frame 12, a set of independent V-wheel systems and a ball screw lifting mechanism. The lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com