Abrasive jetting device and method of use thereof

A technology of jetting device and abrasive, applied in abrasive jetting machine tools, abrasives, metal processing equipment, etc., can solve the problems of low degree of sand shot recycling, high operation and maintenance costs, complex equipment structure, etc., to improve surface finish, Small footprint, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

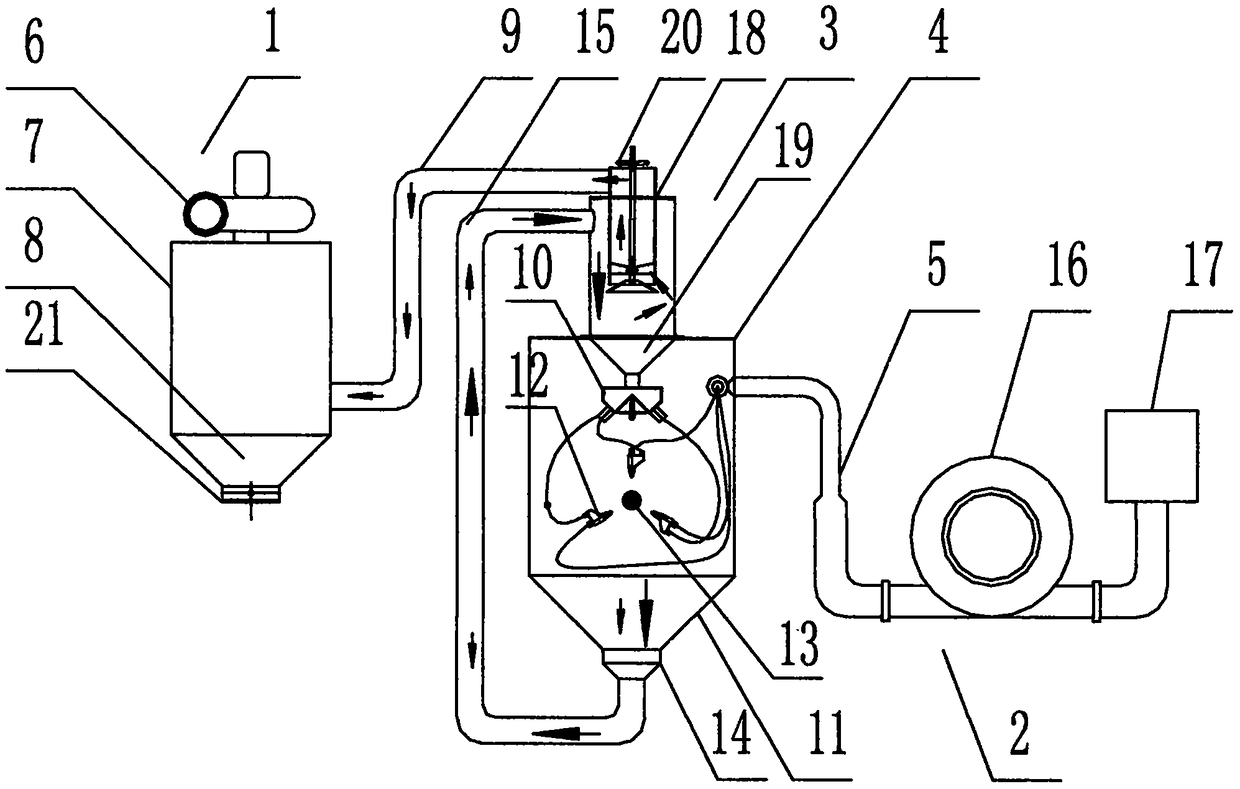

[0024] Attached below figure 1 The structure of the abrasive blasting device of the present invention and its use method are described in detail.

[0025]An abrasive jetting device, the abrasive jetting device includes a base and a jetting assembly mounted on the base, wherein the jetting assembly includes a dust removal system 1, a low-pressure air supply system 2, an abrasive dust separator 3, and a working chamber 4; the The low-pressure air supply system is connected with the working chamber through the low-pressure air duct 5; the abrasive dust separator is connected with the dust removal system and the working chamber respectively; the dust removal system includes a dust removal fan 6, a dust collector 7, and a dust chamber 8. The dust collector is connected to the dust removal fan and the dust chamber respectively; the dust collector is connected to the abrasive dust separator through the dust conveying pipe 9; The abrasive distributor is connected with the abrasive du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com