Rubber plug cleaning machine

A rubber stopper cleaning machine and cleaning box technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as inability to export and transfer, increase labor costs and work complexity, and achieve Conducive to the effect of centralized management and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in terms of specific embodiments in conjunction with the accompanying drawings. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It is to be noted that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the invention.

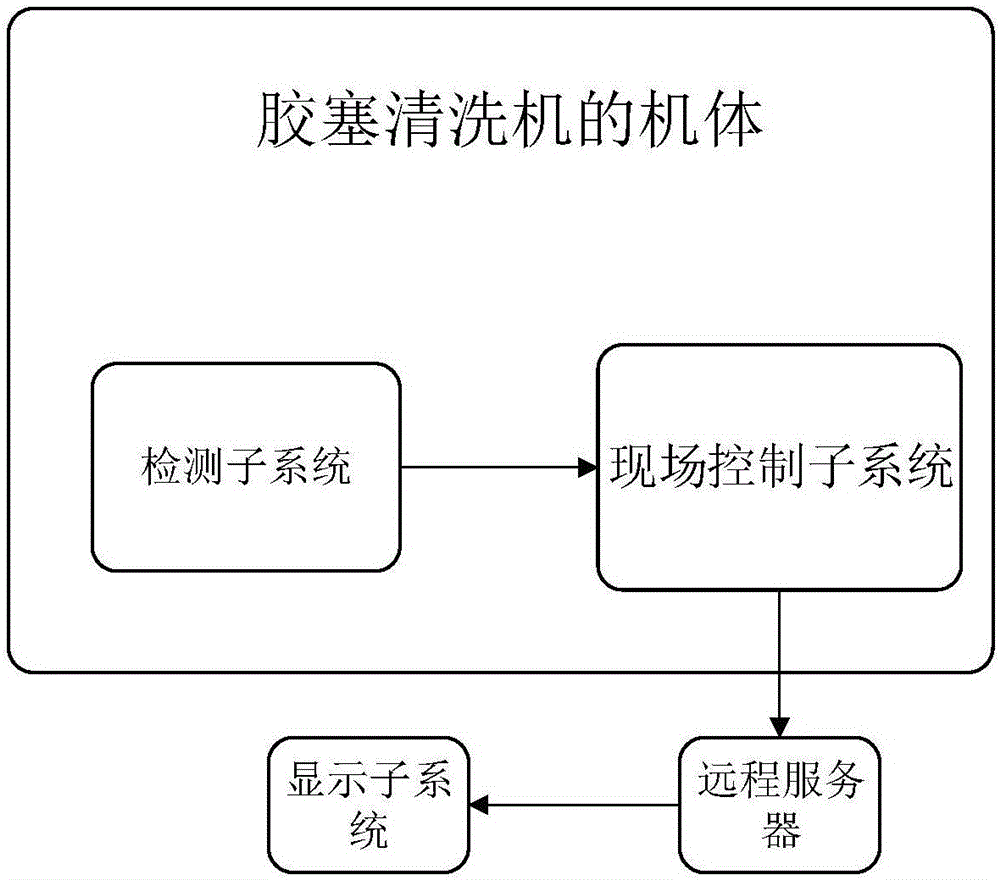

[0036] In the embodiment of a kind of rubber stopper washing machine provided by the present invention, as figure 1 As shown, it includes the body, and the body further includes a bucket, a cleaning box, a transmission device and a pipeline part, and also includes a monitoring system;

[0037] The monitoring system includes a display subsystem, a detection subsystem, an on-site control subsystem and a remote server;

[0038] The detection subsystem is used to detect the body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com