A high-gravity intermittent gas decontamination device

An intermittent, high-gravity technology, applied in the direction of gas treatment, separation methods, and dispersed particle separation, can solve the problems of inability to meet the requirements of gas-liquid contact reaction time and low processing efficiency, and achieve favorable removal effects and increase gas-liquid The effect of contact pressure and guaranteed gas-liquid contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

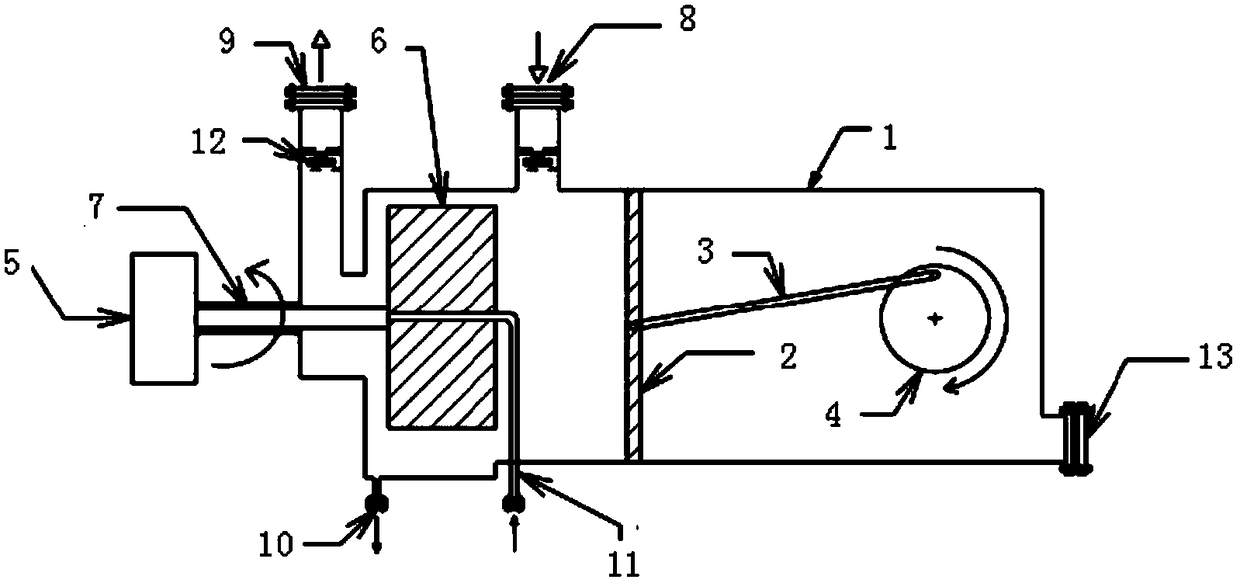

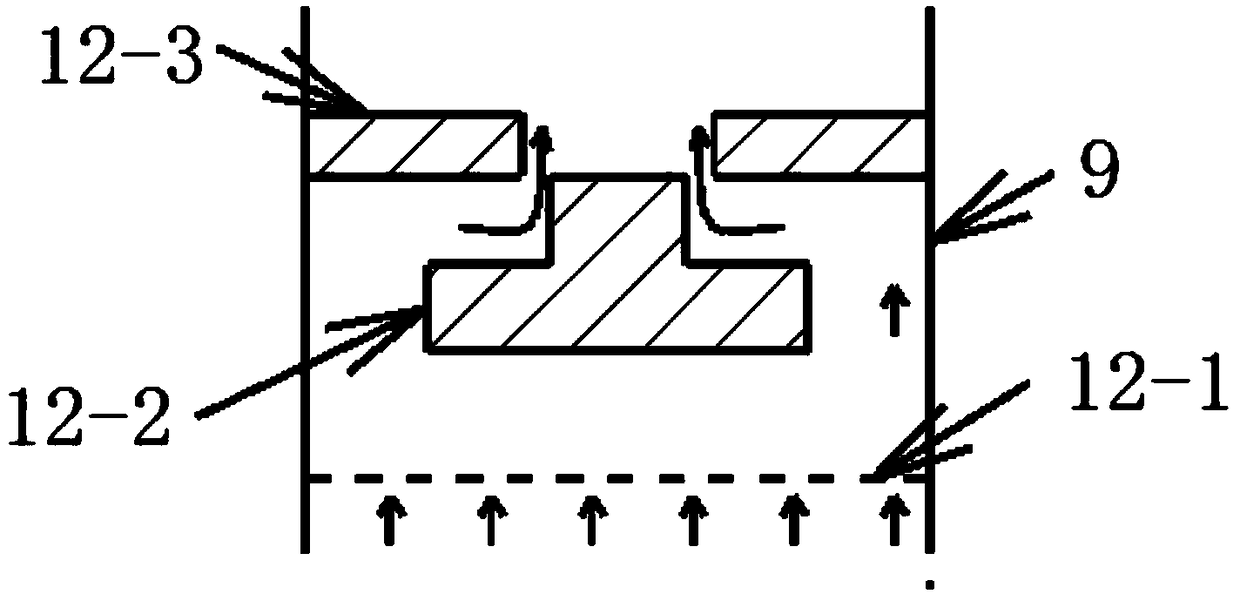

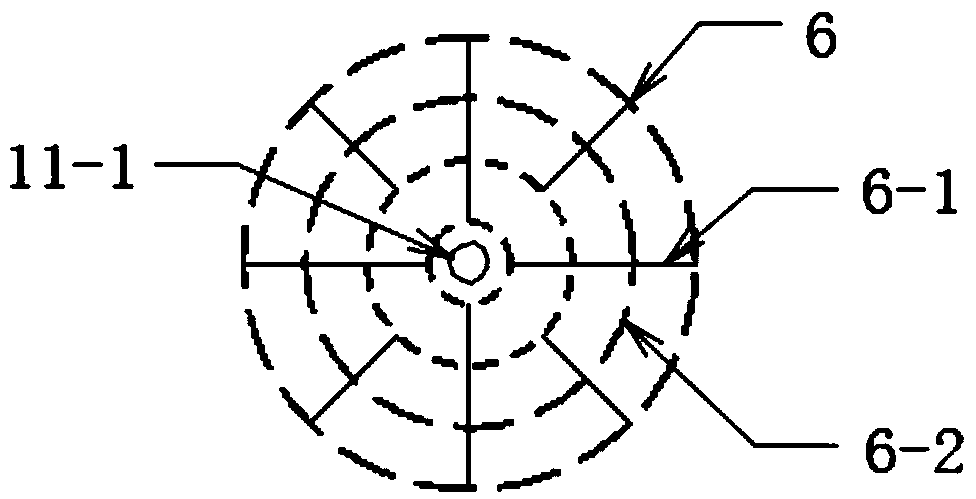

[0022] A high-gravity intermittent gas decontamination device, such as Figure 1 to Figure 4 As shown, the shell 1 is included, and the two ends of the shell 1 are respectively provided with an air inlet pipe 8 and an air outlet pipe 9, and an intermittent valve 12 is respectively arranged in the air inlet pipe 8 and the air outlet pipe 9, and the shell 1 is provided with a sealing plate 2, and the sealing plate 2 is sealed. One end of the plate 2 is connected with the push-pull rotating device, the right end of the shell 1 is provided with a pipe 13 communicating with the atmosphere, the other end of the sealing plate 2 is provided with a liquid phase application pipe 11, and the end of the liquid phase application pipe 11 is provided on the pipe wall. There is an opening 11-1, the terminal of the liquid phase application pipe 11 is set on the rotary bed 6, the lower end of the shell 1 is provided with a liquid phase outlet 10, and the rotary bed 6 is connected with the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com