Method for processing broad bean straws into feed

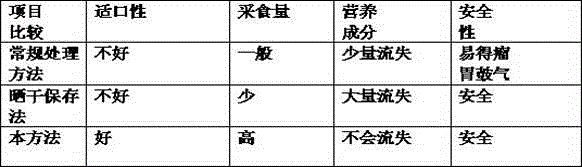

A broad bean straw and processing method technology, which is applied in the field of broad bean straw feed processing, can solve the problems of concentrated output of broad bean straw, low sugar content of broad bean straw, and difficulty in silage alone, achieving good palatability, rich nutrition, and improved fermentation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A processing method for turning broad bean stalks into feed, the processing method comprising the following steps:

[0017] 1) Material selection: select the stem and leaf part above the soil of fresh broad bean stalks, without soil and roots;

[0018] 2) Drying: the water content of fresh broad bean stalks is controlled at 65%;

[0019] 3) Cutting short: Use a straw grinder to crush the dried fresh broad bean straw into 3cm length;

[0020] 4) Starter formula: 10kg of corn flour, 100g of starter, 100g of calcium hydrogen phosphate, 500g of urea, mixed fully and evenly;

[0021] 5) Mixing: Put 1000kg of the material in step 3 and the mixture in step 4 into the mixer and mix evenly;

[0022] 6) Anaerobic treatment: compact and seal the material obtained in step 5 with a storage tank or film;

[0023] 7) Biological feed: The sealed mixture under step 6 is anaerobically fermented for 25 days. After fermentation, it has a special sour aroma, and is fed to cattle and shee...

Embodiment 2

[0025] A processing method for turning broad bean stalks into feed, the processing method comprising the following steps:

[0026] 1) Material selection: select the stem and leaf part above the soil of fresh broad bean stalks, without soil and roots;

[0027] 2) Drying: the water content of fresh broad bean stalks is controlled at 68%;

[0028] 3) Cutting short: Use a straw grinder to crush the dried fresh broad bean straw into 5cm lengths;

[0029] 4) Starter formula: 12kg of corn flour, 110g of starter, 110g of calcium hydrogen phosphate, 540g of urea, mixed fully and evenly;

[0030] 5) Mixing: put the 1040kg material in step 3 and the mixture in step 4 into the mixer and mix evenly;

[0031] 6) Anaerobic treatment: compact and seal the material obtained in step 5 with a storage tank or film;

[0032] 7) Biological feed: The sealed mixture under step 6 is anaerobically fermented for 20 days. After fermentation, it has a special sour aroma, and is fed to cattle and sheep ...

Embodiment 3

[0034] A processing method for turning broad bean stalks into feed, the processing method comprising the following steps:

[0035] 1) Material selection: select the stem and leaf part above the soil of fresh broad bean stalks, without soil and roots;

[0036] 2) Drying: the water content of fresh broad bean stalks is controlled at 62%;

[0037] 3) Cutting short: Use a straw grinder to crush the dried fresh broad bean straw into 2cm length;

[0038] 4) Starter formula: 8kg of corn flour, 90g of starter, 90g of calcium hydrogen phosphate, 540g of urea, mixed fully and evenly;

[0039] 5) Mixing: put the 960kg material in step 3 and the mixture in step 4 into the mixer and mix evenly;

[0040] 6) Anaerobic treatment: compact and seal the material obtained in step 5 with a storage tank or film;

[0041] 7) Biological feed: The sealed mixture under step 6 is anaerobically fermented for 30 days. After fermentation, it has a special sour aroma, and is fed to cattle and sheep as hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com