Method of producing Fu tea from artificial fermentation tea leaves and bacterial strain

A tea and artificial technology, applied in the production of Fucha, can solve the problems of poor control of the production process and quality, affect the sensory quality, and harm to the human body, achieve controllable production process and quality, break the technical barriers of the industry, and reduce costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

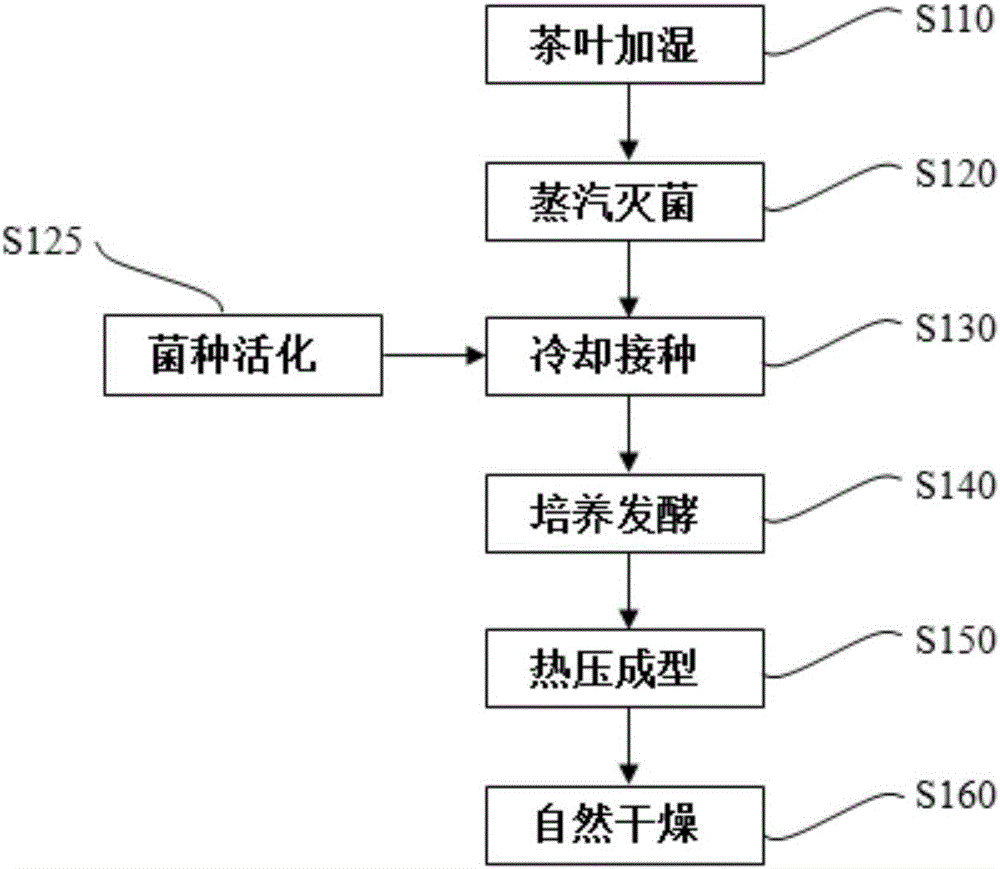

Method used

Image

Examples

Embodiment 1

[0046] 1). Activation of strains: Transplant CGMCC No.3.15516 frozen on PDA (Potato Dextrose Agar Medium) slant medium to PDA plate and culture at 25° C. for 7 days.

[0047] 2). Select tea raw materials: bulk green tea, purchased from Yanting Tea Factory in Ningde City, Fujian Province (other teas are also applicable).

[0048] 3). Humidification of tea leaves: 300 grams of dry tea leaves are placed in a 3000 ml Erlenmeyer flask, spray and humidify the tea leaves to make the water content 30%, and cover with a sealing film.

[0049] 4). Steam sterilization: Put the humidified tea leaves together with the Erlenmeyer flask in an ordinary steamer, and carry out 40 minutes of steam damp heat sterilization after reaching 110-120°C.

[0050] 5). Cooling inoculation: cool the sterilized tea leaves to below 40°C, and in a sterile environment, remove the activated Saccharomyces coronatum on the PDA plate, and cut out about 0.25 square centimeters of strains with a sterile inoculation ...

Embodiment 2

[0055] 1). Activation of strains: Transplant CGMCC No. 3.15516 frozen on PDA slant medium to PDA plate and culture at 25° C. for 7 days.

[0056] 2). Select tea raw materials: green tea, purchased from Yanting Tea Factory in Ningde City, Fujian Province (other teas are also applicable).

[0057] 3). Humidification of tea leaves: 300 grams of dry tea leaves are placed in a 3000 ml Erlenmeyer flask, after spraying and humidification of the tea leaves, the water content is 35%, and the sealing film is covered.

[0058] 4). Steam sterilization: Put the humidified tea leaves together with the Erlenmeyer flask in an ordinary steamer, and carry out 40 minutes of steam damp heat sterilization after reaching 110-120°C.

[0059] 5). Cooling inoculation: cool the sterilized tea leaves to below 40°C, and in a sterile environment, remove the activated Saccharomyces coronatum on the PDA plate, and cut out about 0.25 square centimeters of strains with a sterile inoculation shovel. Quickly pla...

Embodiment 3

[0064] 1). Activation of strains: Transplant CGMCC No. 3.15516 frozen on PDA slant medium to PDA plate and culture at 25° C. for 7 days.

[0065] 2). Select tea raw materials: green tea, purchased from Yanting Tea Factory in Ningde City, Fujian Province (other teas are also applicable).

[0066] 3). Humidification of tea leaves: 300 grams of dry tea leaves are placed in a 3000 ml Erlenmeyer flask, spray and humidify the tea leaves to make the water content 40%, and cover with a sealing film.

[0067] 4). Steam sterilization: Put the humidified tea leaves together with the Erlenmeyer flask in an ordinary steamer, and carry out 40 minutes of steam damp heat sterilization after reaching 110-120°C.

[0068] 5). Cooling inoculation: cool the sterilized tea leaves to below 40°C, and in a sterile environment, remove the activated Saccharomyces coronatum on the PDA plate, and cut out about 0.25 square centimeters of strains with a sterile inoculation shovel. Quickly place it in a Erl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com