Electric rotary machine

A technology of electric rotation and rotating shafts, which is applied in the manufacture of motor generators, electric components, synchronous motors for single-phase current, etc., and can solve problems such as difficulty in adopting special structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

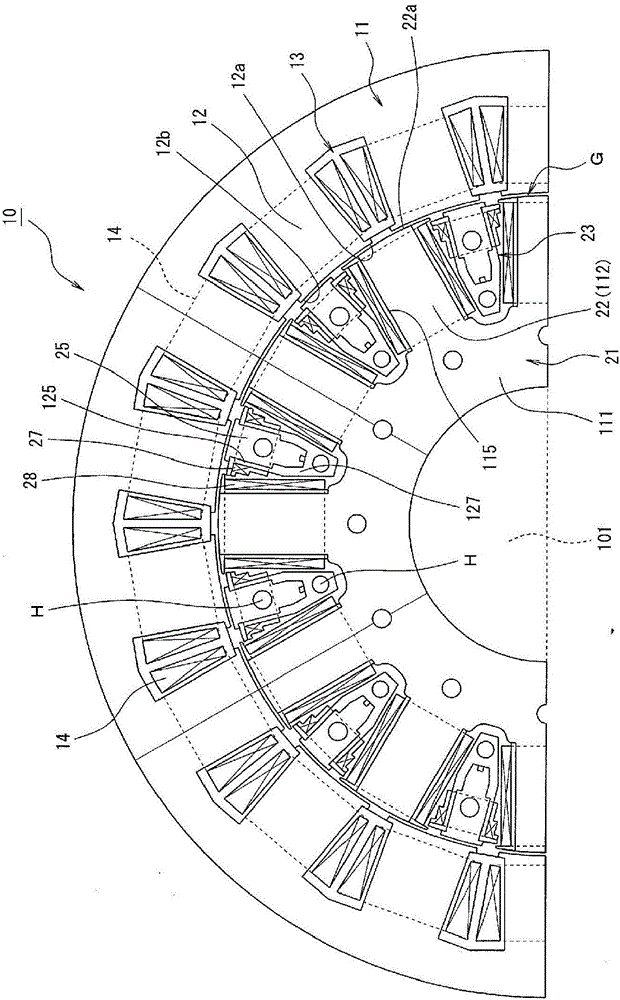

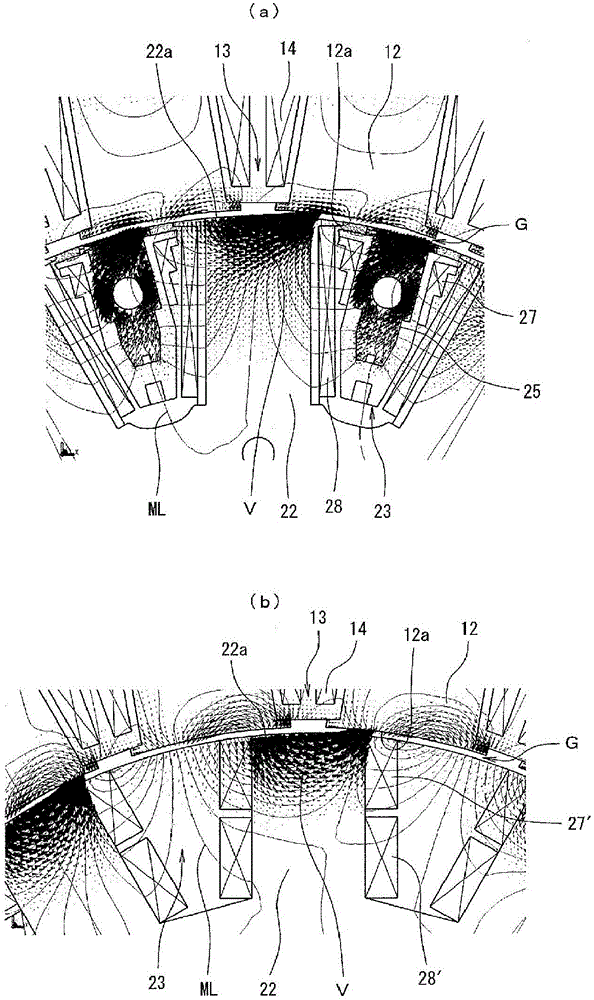

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. Figure 1 to Figure 10 It is a figure for demonstrating an example of the reluctance motor which is one embodiment of the electric rotating machine of this invention. figure 1 It is a radial cross-sectional view of a reluctance motor, showing that the mechanical angle around the shaft center is 180 degrees, and the same structures are juxtaposed in the circumferential direction to make a reluctance motor.

[0028] As described later, figure 1 The shown reluctance motor (electric rotating machine) 10 has a structure that does not require energy input to the rotor 21 from the outside, and is suitable for mounting in, for example, a hybrid vehicle or an electric vehicle.

[0029] (Basic structure of the reluctance motor 10)

[0030] The reluctance motor 10 is provided with: a stator 11 formed in a substantially cylindrical shape; and a rotor 21 housed in the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com