Intelligent control method with predictive emissions monitoring ability

A control unit and a predetermined threshold technology, which are applied in the direction of fuel control, combustion method, and control combustion of turbine/propulsion devices, and can solve problems such as variable fuel composition without considering pilot fuel diversion fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The illustrations in the figures are schematic. It should be noted that similar or identical elements are provided with the same reference signs in different figures.

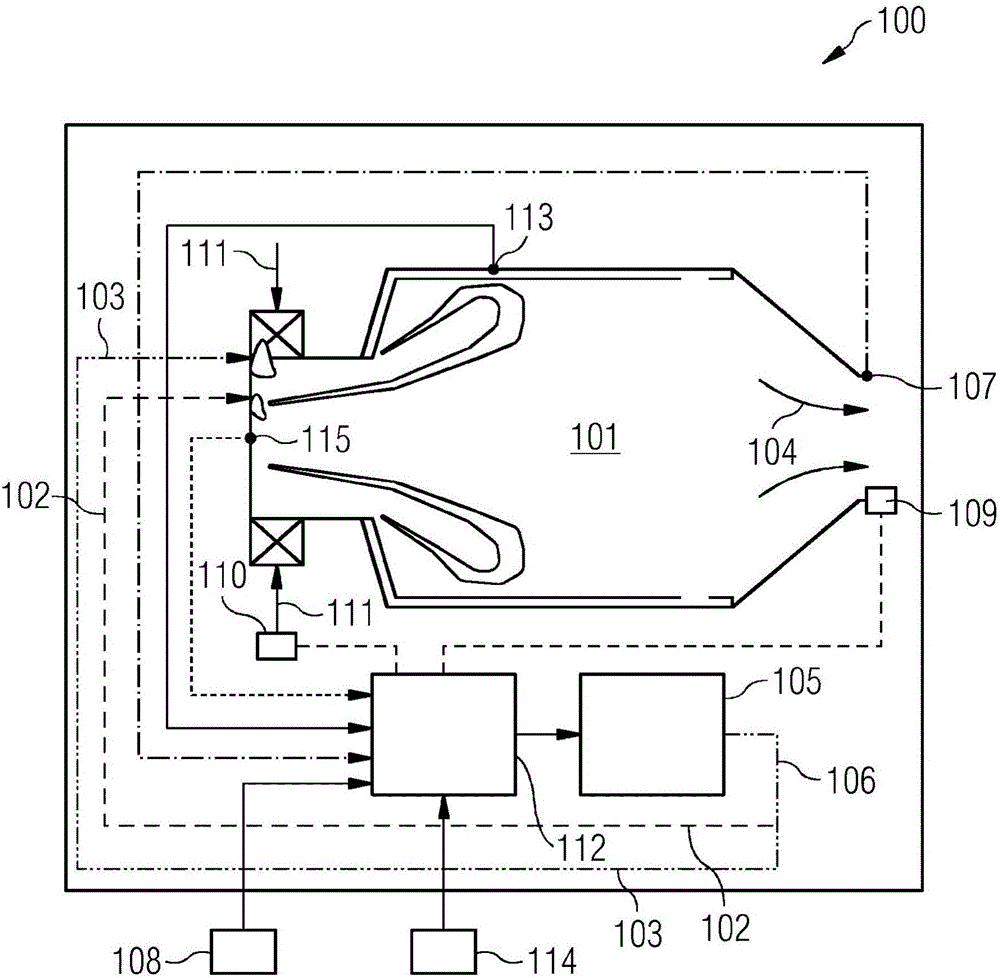

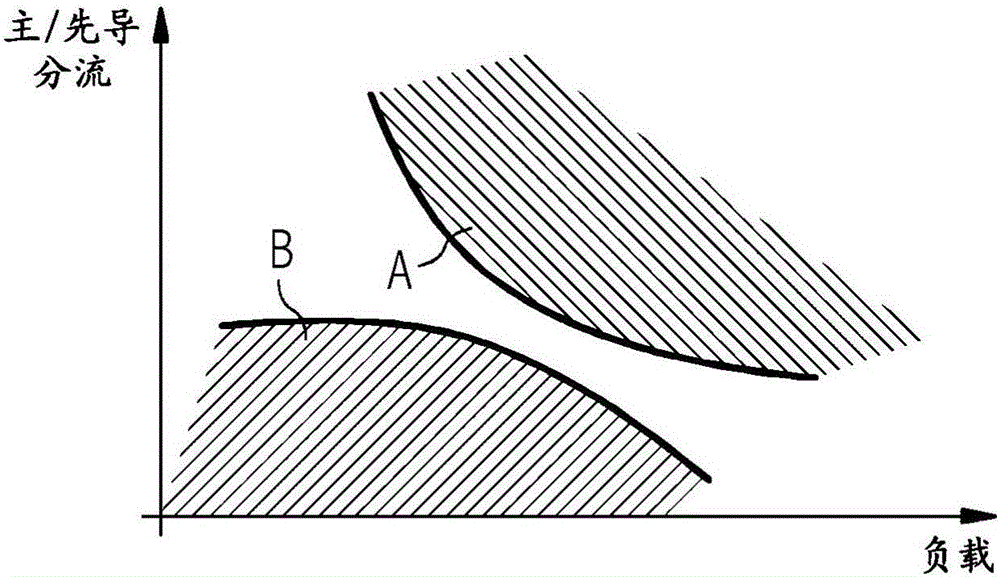

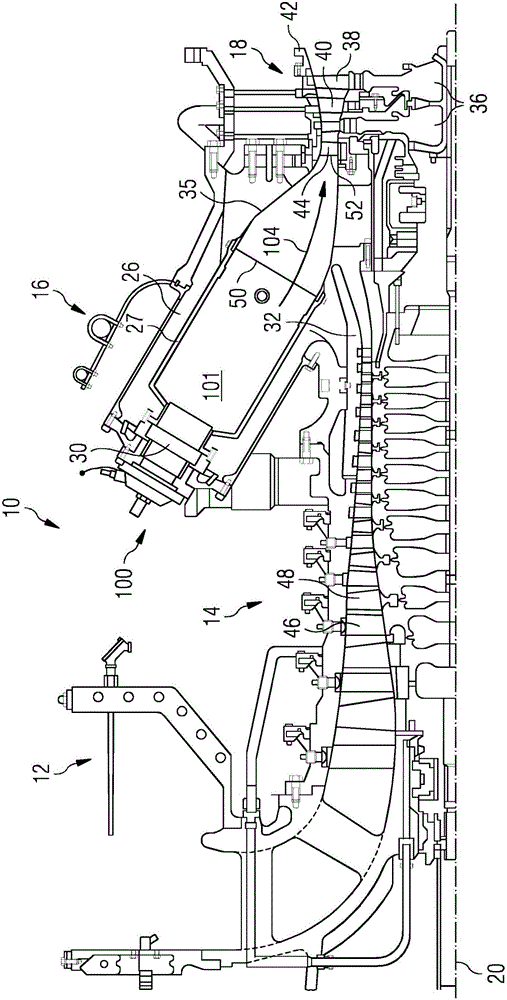

[0051] figure 1 A combustion system 100 for a gas turbine engine 10 is shown according to an exemplary embodiment of the invention. The combustion system 100 includes a combustion chamber 101 into which a pilot fuel 102 and a main fuel 103 may be injected and combusted therein. Exhaust gas 104 resulting from combusted pilot fuel 102 and combusted main fuel 103 may be exhausted from combustion chamber 101 . The fuel control unit 105 divides the fuel 106 into a pilot fuel 102 and a main fuel 103 in consideration of an adjustable pilot fuel / main fuel ratio. The temperature sensor 107 generates a temperature signal indicative of the temperature of the exhaust gas 104 at a location inside the combustion chamber 101 . The fuel determination unit 109 determines a fuel signal indicative of the fuel compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com