Graft-modified propylene/alpha-olefin copolymer and method for producing same

一种烯烃共聚物、接枝改性的技术,应用在接枝改性丙烯·α-烯烃共聚物领域,能够解决成品率降低、臭气、白浊等问题,达到高成品率、确保成品率、乳化性稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] [Method for producing propylene-α-olefin copolymer (a)]

[0093] The propylene / α-olefin copolymer (a) used in the present invention can be produced using a multi-site catalyst such as a Ziegler catalyst or a single-site catalyst such as a metallocene catalyst. Polymerization of propylene and α-olefin can be carried out by any method of liquid phase polymerization or gas phase polymerization such as suspension polymerization and solution polymerization.

[0094]

[0095] The graft-modified propylene / α-olefin copolymer (A) of the present invention can be obtained by graft-polymerizing a polar monomer onto the above-mentioned propylene / α-olefin copolymer (a).

[0096] Examples of the polar monomer include hydroxyl-containing ethylenically unsaturated compounds, amino-containing ethylenically unsaturated compounds, epoxy-containing ethylenically unsaturated compounds, aromatic vinyl compounds, unsaturated As carboxylic acids and their derivatives, vinyl ester compounds, ...

Embodiment

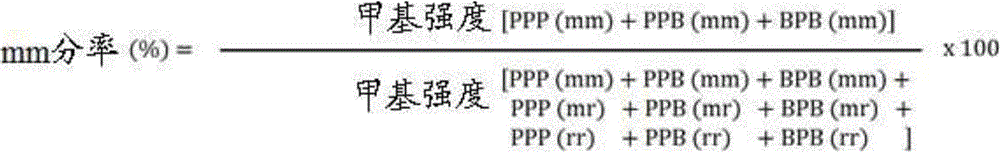

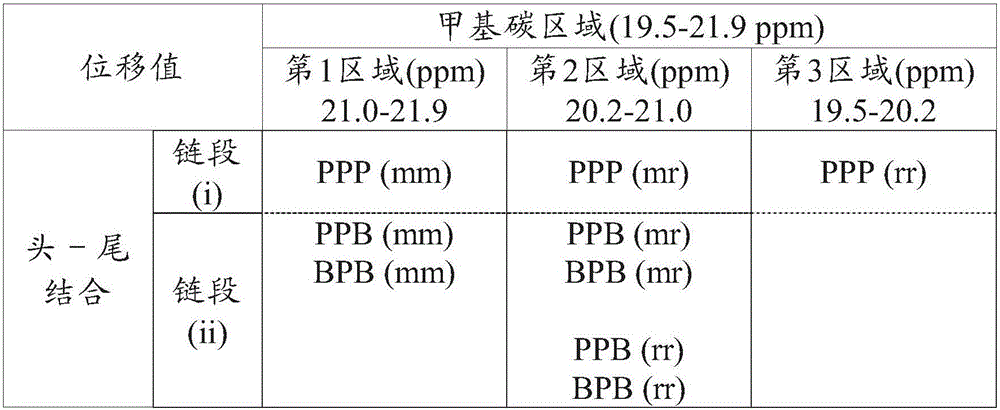

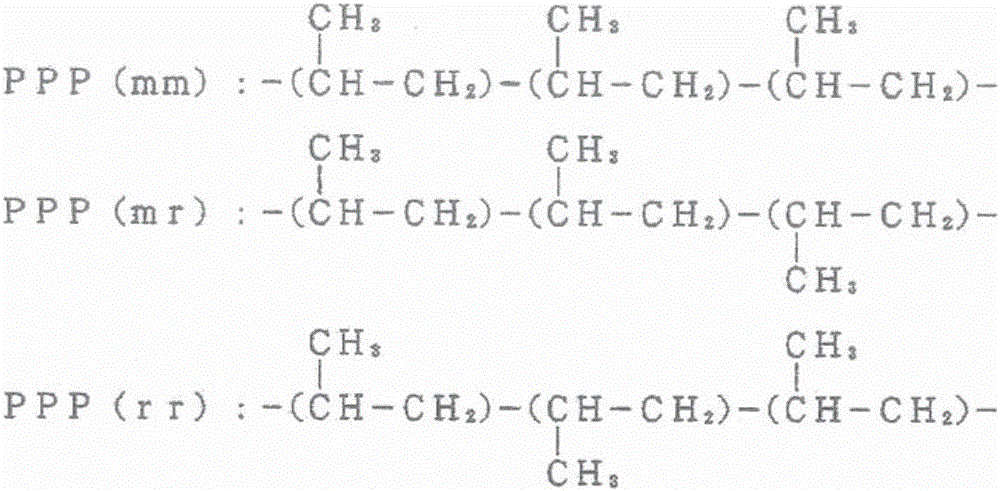

[0138] In the following examples, the physical properties and the like of the polymer were measured as follows.

[0139] (1) 1-butene content

[0140] For 1-butene content, use 13 Calculated by C-NMR.

[0141] (2) Melt flow rate (MFR)

[0142] The melt flow rate is measured at 230° C. under a load of 2.16 kg in accordance with ASTM D1238.

[0143] (3) Molecular weight distribution (Mw / Mn)

[0144] The molecular weight distribution (Mw / Mn) was measured as follows using GPC-150C manufactured by Millipore Corporation.

[0145] The separation column is TSKGNHHT, and the column size is 27 mm in diameter and 600 mm in length. The temperature of the column is 140° C., and the mobile phase uses o-dichlorobenzene (Wako Pure Chemical Industries) and 0.025% by weight of BHT (Takeda Pharmaceutical) as an antioxidant. ml / min was flowed so that the sample concentration was 0.1% by weight, and the sample injection volume was 500 microliters, and a differential refractometer was used as ...

manufacture example 1

[0166] In a 2-liter autoclave fully replaced with nitrogen, 900 ml of hexane and 90 g of 1-butene were charged, 1 mmol of triisobutylaluminum was added, and after the temperature was raised to 70° C., propylene was supplied so that the total pressure was 7 kg / cm 2 G, add 0.30 millimoles of methyl aluminoxane, converted into rac-dimethylsilylene-bis{1-(2-methyl-4-phenylindenyl)}bis with 0.001 millimoles of Zr atoms Zirconium chloride, while continuously supplying propylene to keep the total pressure at 7kg / cm 2 The G side was polymerized for 30 minutes. After the polymerization, degassing was carried out, and the polymer was recovered in a large amount of methanol, and dried under reduced pressure at 110° C. for 12 hours.

[0167] The obtained propylene·α-olefin polymer (a-1) was 39.7 g, and the polymerization activity was 79 kg·polymer / mmol Zr·hr. The polymer contained 74 mole % of units derived from propylene and 26 mole % of units derived from 1-butene. MFR was 7 g / 10 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com