Ni-Co composite oxide and preparation method thereof

A composite oxide, nickel-cobalt technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of metal ion waste, increase production cost, and reduce product recovery rate, and achieve improved recovery rate, good sphericity, and vibration. High solid density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

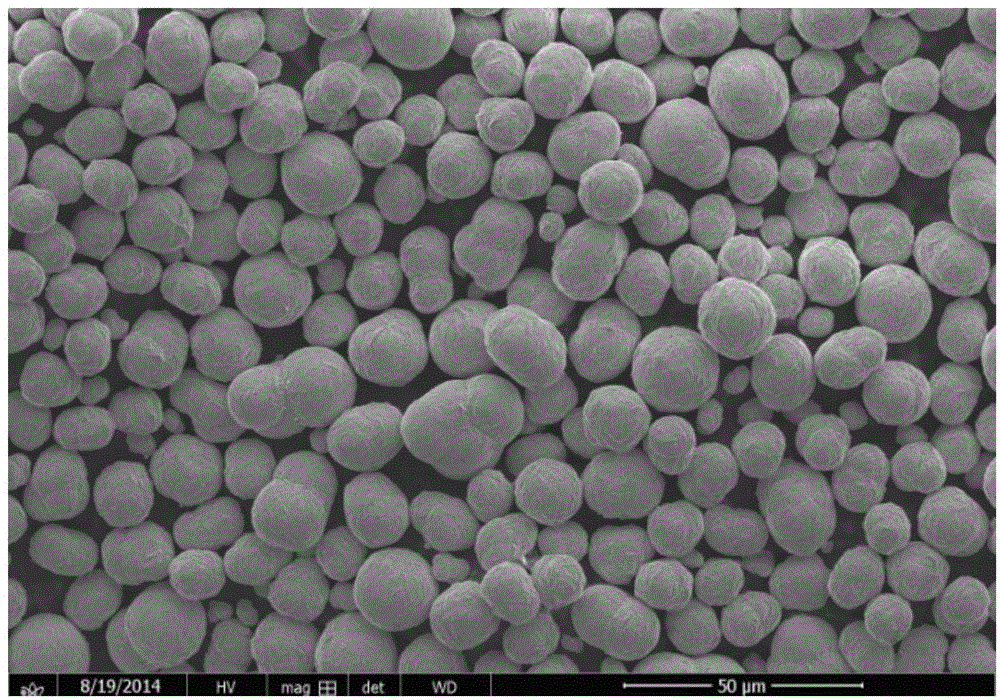

Embodiment 1

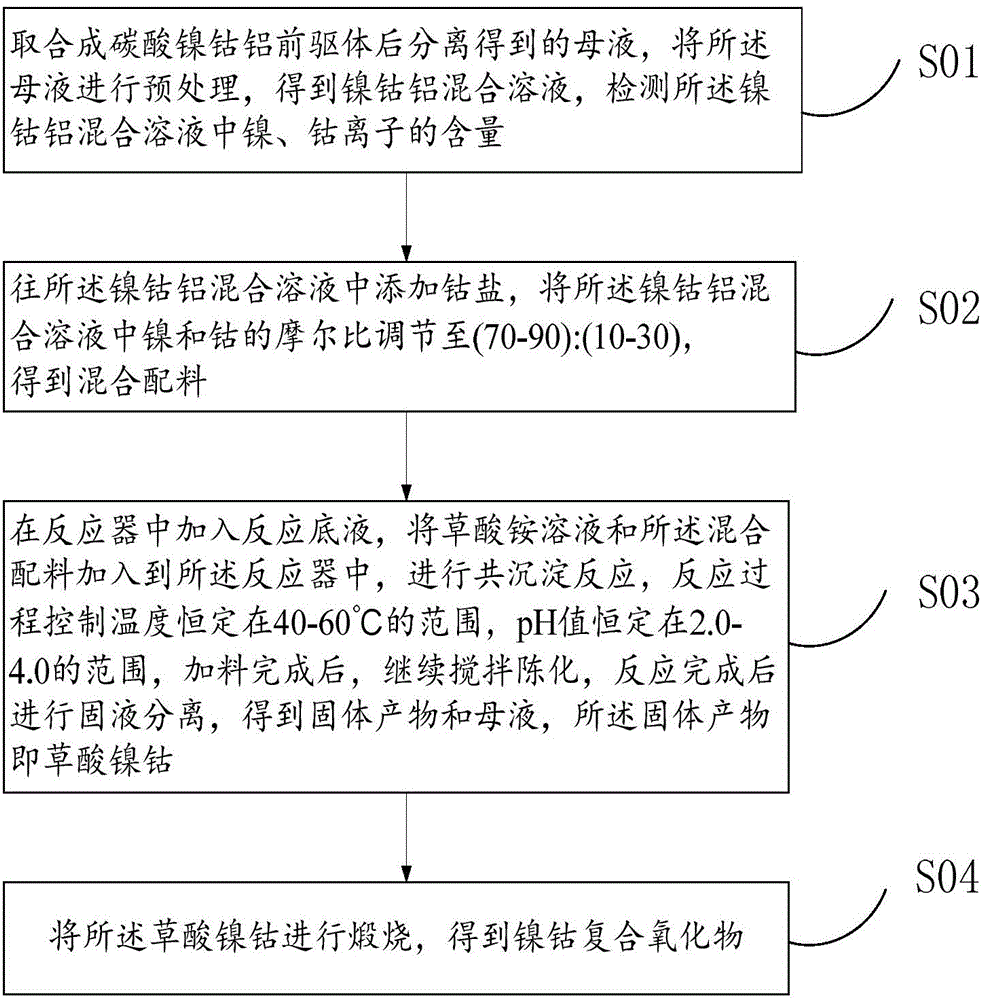

[0053] A preparation method of nickel-cobalt composite oxide, comprising the following steps:

[0054] (1) get the mother liquor 50L after nickel-cobalt-aluminum carbonate centrifugation, wherein, nickel ion concentration is 4.21g / L, cobalt ion concentration is 61.5mg / L, aluminum ion concentration is 0.1mg / L, filters mother liquor with ultrafiltration machine The solid particles in the nickel-cobalt-aluminum mixed solution are obtained, and the content of nickel and cobalt ions in the nickel-cobalt-aluminum mixed solution is detected;

[0055] (2) adding a certain amount of CoCl to the nickel-cobalt-aluminum mixed solution 2 crystals, and mix them uniformly, adjust the molar ratio of nickel and cobalt in the mixed batch to be 75:25, to obtain a mixed batch, and the total concentration of nickel-cobalt metal ions in the mixed batch is 80g / L;

[0056] (3) adding 3L of pure water to the reactor with a volume of 50L, adding the ammonium oxalate solution of 80g / L, adjusting the pH...

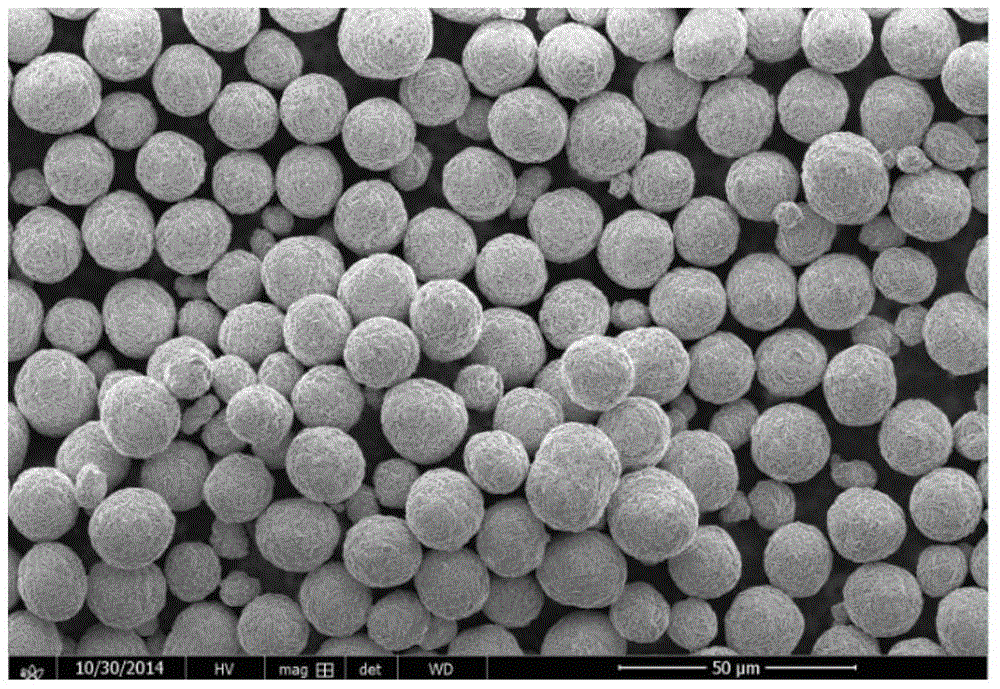

Embodiment 2

[0061] A preparation method of nickel-cobalt composite oxide, comprising the following steps:

[0062] (1) get the mother liquor 100L after the nickel-cobalt-aluminum carbonate centrifugation, wherein, the nickel ion concentration is 4.96g / L, the cobalt ion concentration is 67.5mg / L, and the aluminum ion concentration is 0.2mg / L, and the mother liquor is filtered with an ultrafiltration machine The solid particles in the nickel-cobalt-aluminum mixed solution are obtained, and the content of nickel and cobalt ions in the nickel-cobalt-aluminum mixed solution is detected;

[0063] (2) adding a certain amount of CoCl to the nickel-cobalt-aluminum mixed solution 2 crystals, and mix them evenly, adjust the molar ratio of nickel and cobalt in the mixed batch to be 80:20 to obtain a mixed batch, and the total concentration of nickel-cobalt metal ions in the mixed batch is 80g / L;

[0064] (3) adding 3L of pure water to the reactor with a volume of 50L, adding the ammonium oxalate sol...

Embodiment 3

[0069] A preparation method of nickel-cobalt composite oxide, comprising the following steps:

[0070] (1) get the mother liquor 100L after the nickel-cobalt-aluminum carbonate centrifugation, wherein, the nickel ion concentration is 5.03g / L, the cobalt ion concentration is 63.4mg / L, and the aluminum ion concentration is 0.4mg / L, and the mother liquor is filtered with an ultrafiltration machine The solid particles in the nickel-cobalt-aluminum mixed solution are obtained, and the content of nickel and cobalt ions in the nickel-cobalt-aluminum mixed solution is detected;

[0071] (2) adding a certain amount of CoCl to the nickel-cobalt-aluminum mixed solution 2 crystals, and mix them evenly, adjust the molar ratio of nickel and cobalt in the mixed batch to be 85:15 to obtain a mixed batch, and the total concentration of nickel-cobalt metal ions in the mixed batch is 100 g / L;

[0072] (3) adding 3L pure water to the reaction kettle with a volume of 50L, adding the ammonium oxal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com