Separation method of non-metallic inclusions in inconel625 series superalloys

A technology for non-metallic inclusions and high-temperature alloys, applied in the field of separation of non-metallic inclusions in Inconel625 series superalloys, can solve the problem of small content and size of non-metallic inclusions, shedding of the matrix, affecting the observation and analysis of non-metallic inclusions, etc. problem, to avoid severe shedding, and achieve the effect of uniform alloy matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

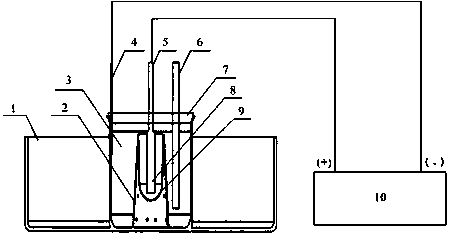

[0017] The present invention is the separation method of non-metallic inclusions in Inconel625 series superalloy, and its steps are:

[0018] (1) Workpiece preparation: Cut the rod-shaped workpiece at the position where the inclusions of the alloy ingot are enriched by machining; put the cut workpiece in acetone solution and clean it with ultrasonic vibration for about 10 minutes;

[0019] (2) Heat treatment: Use a box-type resistance furnace to perform two-stage solid solution treatment on the cleaned workpiece. The specific heat treatment process is: 1130-1170 °C for 1 hour, heat up to 1200-1210 °C for 1 hour, and water cooling;

[0020] (3) Make a semi-permeable plastic bag: pour a small amount of liquid collodion into a reaction container with a suitable capacity according to the size of the workpiece, turn the container so that a layer of collodion is evenly attached to the inner wall, pour out the excess liquid, and wait for the collodion When dry, carefully tear it off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com