Self-lubricating self-sealing ball socket structure based on polytetrafluoroethylene material

A polytetrafluoroethylene, self-sealing technology, applied in the direction of jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of restricted use range, easy volatilization and aging, high friction coefficient, etc., and achieve simple structure and temperature adaptability Strong performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

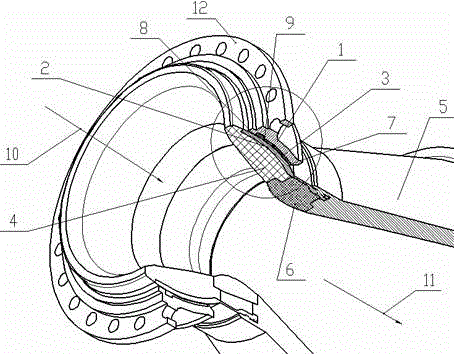

[0011] As shown in the figure, a self-lubricating and self-sealing ball socket structure based on polytetrafluoroethylene material according to the embodiment of the present invention mainly includes: female ball 1, male ball 2, polytetrafluoroethylene lining 3, polytetrafluoroethylene Lining rear gap 7, polytetrafluoroethylene lining front gap 8, polytetrafluoroethylene lining limit step 9. In this embodiment, the gas inlet direction 10, the gas outlet direction 11, and the front connecting flange 12 of the female sphere are as follows: figure 1 shown. The number of the female sphere 1 is 1, the number of the male sphere 2 is 1, the number of the polytetrafluoroethylene lining 3 is 1, the number of the male sphere 4 is 1, the number of the nozzle diffusion section 5 is 1, and the throat lining 6 is 1 1 piece, PTFE lining rear gap 7 quantity 1 place, PTFE lining front gap 8 quantity 1 place, PTFE lining limit step 9 quantity 1 place, female ball front connecting flange 12 qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com