Spiral conveyer sealing device

A technology of screw conveyor and sealing device, applied in the field of chip conveying device and sealing device of screw conveyor, can solve the problems of small occupied space and outflow of cutting fluid, and achieve the effect of small occupied space, improved stability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

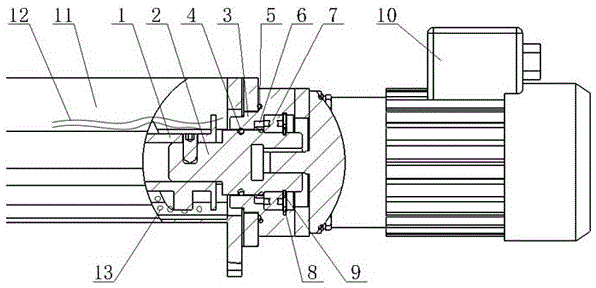

[0014] A sealing device for a screw conveyor, including a screw rod 1, a connecting shaft 2, a bearing seat 3, a small O-shaped sealing ring 4, a large O-shaped sealing ring 5, a lip-shaped sealing ring 6, a bearing 7, and an elastic retaining ring 8 for holes , shaft circlip 9, motor 10, spiral groove body 11, characterized in that the bearing seat 3 is fixed in the hole at the right end of the spiral groove body 11, wherein the left end of the bearing seat is a stepped structure, the first step surface and the The right end surface of the spiral groove body 11 is in contact, and the large O-shaped sealing ring 5 is fixed in the groove provided on the first step surface of the bearing seat 3. The lip seal ring 6 and the bearing 7 are installed in the bearing seat 3, and the lip seal The ring 6 is near the end of the screw rod 1, and the circlip 8 for the hole is installed in the bearing seat 3 to fix the lip seal ring 6 and the bearing 7; the connecting shaft 2 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com