Novel ultra-thin microalloy high-strength steel and preparation method thereof

A micro-alloy and high-strength steel technology, applied in the field of ultra-thin new micro-alloy high-strength steel and its preparation, can solve the problem that thickness specifications cannot meet ultra-thin thickness requirements, and achieve good market application prospects, excellent comprehensive performance, and stable mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

[0027] Chemical composition design:

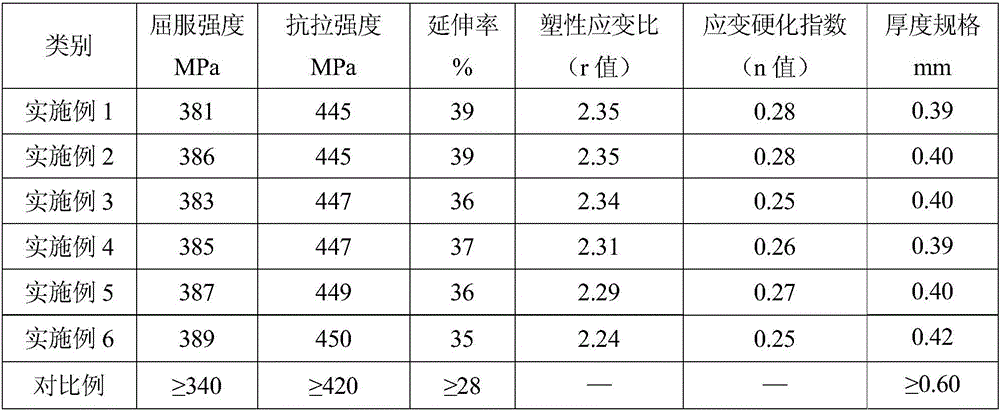

[0028] The chemical composition and weight percentage of the ultra-thin new microalloyed high-strength steel of Examples 1 to 6 and the comparative steel are shown in Table 1;

[0029] The manufacturing methods of the ultra-thin new microalloyed high-strength steel of Examples 1 to 6 are as follows:

[0030] 1) Grind pure Fe, C rod, electrolytic Mn, single crystal Si, Ti, V metals into powder particles according to their respective composition ratios;

[0031] 2) Use SLS carbon dioxide laser equipment to make the original steel plate with a thickness of 0.41~0.45mm, and the laser power is 100~150W;

[0032] 3) After a 2-high cold rolling mill with a cold rolling reduction ratio of 5 to 7%, a finished steel plate with a thickness of 0.39 to 0.42 mm is obtained;

[0033] 4) Use CCT-AWY thin plate steel plate heat treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com