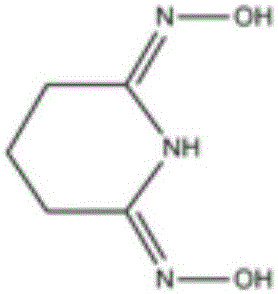

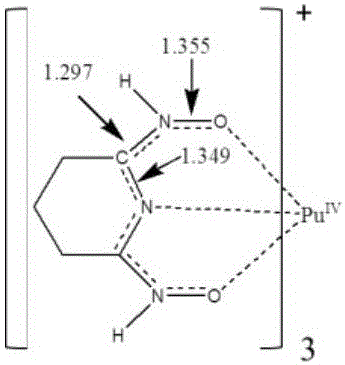

Plutonium purification and concentration method utilizing dioxime imide as reduction and reextraction agent

A technology of dioxime imide and glutaroxime imide, which is applied in the professional field of nuclear fuel reprocessing, can solve the problems of heavy burden of radioactive waste liquid, and achieve the effect of small radiolysis damage and short contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First extract 0.2mL44g / LPu(IV) in 5.5mol / L nitric acid solution into the 30% TBP / kerosene solution quickly to prepare the 30% TBP / kerosene organic phase loaded with 0.87g / LPu(IV), and then add a relatively small The volume of nitric acid solution containing glutdioxime imide reducing stripping agent reduces Pu(IV) to Pu(III), and Pu(III) is stripped into the water phase, so that plutonium can be concentrated and separated.

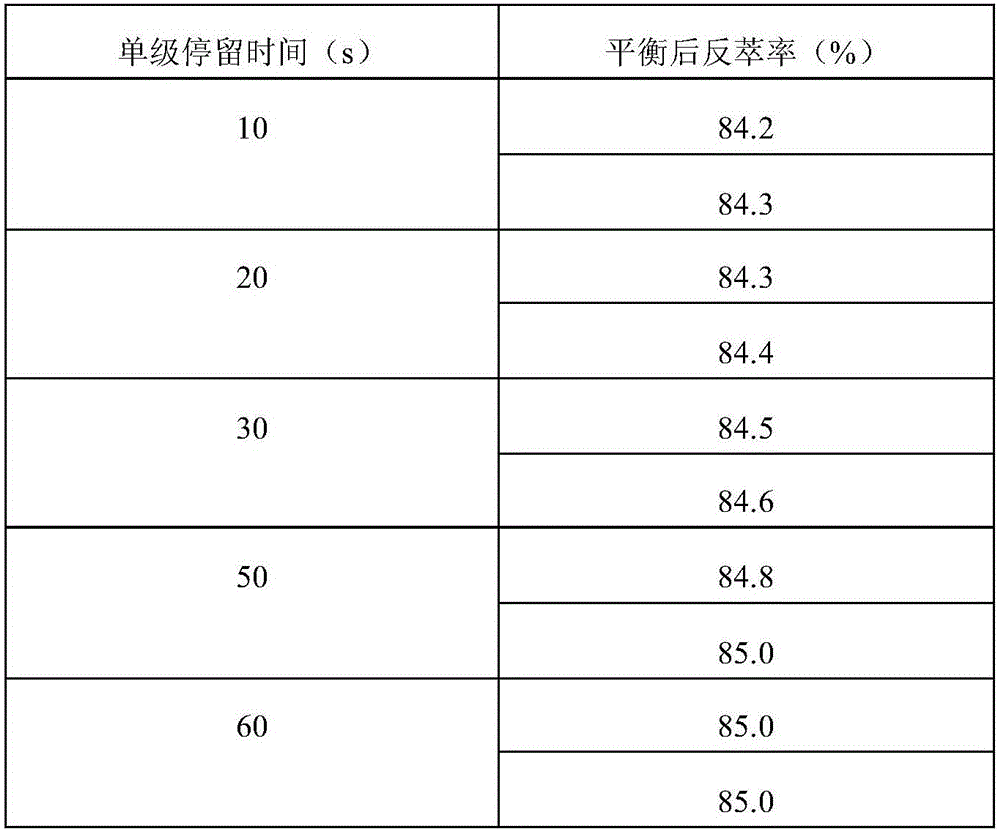

[0030] 1) Effect of single-stage residence time on plutonium stripping yield

[0031] In the single-stage experiment, the influence of the residence (contact) time on the reduction and stripping agent stripping plutonium was investigated. The organic phase was 30% TBP / kerosene loaded with 0.87g / LPu(IV), and the composition of the reduction stripping agent aqueous phase was 0.4 mol / L glutaroxime imide-1mol / L nitric acid, the stripping ratio is organic phase / water phase=10:1, when the single-stage residence time (i.e. stripping time) is 10s, 20s, 30s,...

Embodiment 2

[0039] The difference from Example 1 is that the aqueous phase composition of the reducing stripping agent in the single-stage test is 0.1 mol / L glutaroximide-0.1 mol / L nitric acid.

Embodiment 3

[0041] The difference from Example 1 is that the aqueous phase composition of the reduction stripping agent in the single-stage test is 0.2 mol / L glutaroximide-0.5 mol / L nitric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com