Decoloration method in process for preparing biodiesel from waste cooking oil

A technology of catering waste oil and biodiesel, which is applied in the field of decolorization, can solve the problem of high temperature required, and achieve the effects of improved color, low decolorization temperature and short decolorization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a 100mL conical flask, add 40g of filtered catering waste oil (absorbance A 0 is 1.257), heated to 70°C, firstly added 1.2g of hydrogen peroxide, stirred at 20rpm for 10min, then used a separatory funnel to stand for liquid separation, took the upper liquid, and then added 4g of kaolin with a pore size of 2 to 50nm and 2g of a pore size of 0.5-40nm activated carbon, stirred at 80°C and 20rpm for 30min, took out the decolorized waste catering oil, filtered it with low-speed filter paper immediately, and tested the filtrate with a 722E visible spectrophotometer to measure the absorbance A of the decolorized catering waste oil 1 It is 0.136, and the decolorization rate reaches 89.2%.

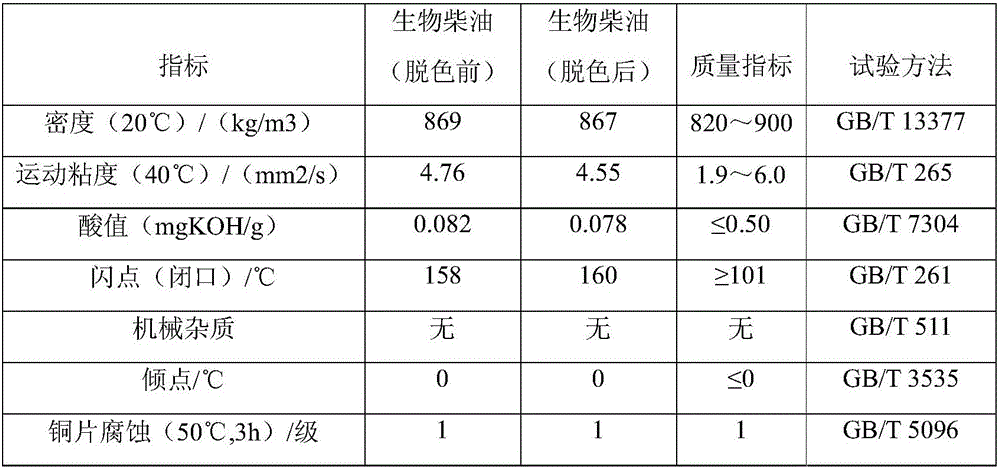

[0029] The comparison of various performance indicators of waste cooking oil before and after decolorization is shown in Table 1.

[0030] Table 1 Comparison of properties of waste catering oil before and after decolorization

[0031] Performance

Before bleaching

After...

Embodiment 2

[0040] In this embodiment, the same filtered waste catering oil is decolorized in the same manner as in Example 1, except that the hydrogen peroxide decolorization temperature is changed to 65°C.

[0041] After testing, the absorbance A of waste catering oil after decolorization 1 was 0.155, and the decolorization rate was 87.7%.

Embodiment 3

[0043] In this embodiment, the same filtered waste catering oil is decolorized in the same manner as in Example 1, except that the hydrogen peroxide decolorization time is changed to 8 minutes.

[0044] After testing, the absorbance A of waste catering oil after decolorization 1 It is 0.150 in turn, and the decolorization rate is 88.1% in turn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com