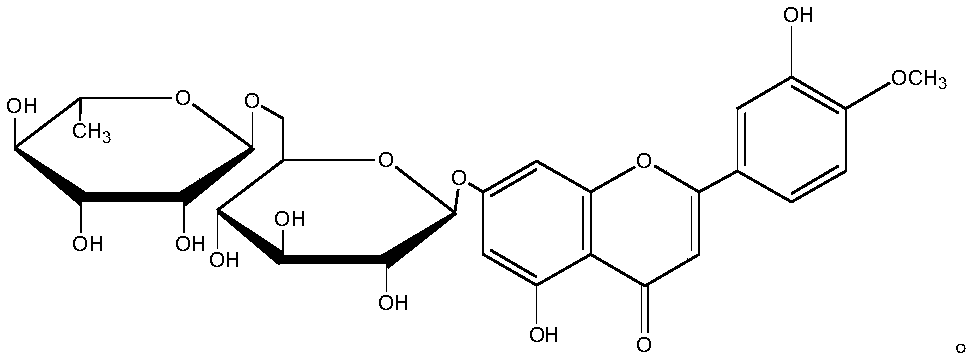

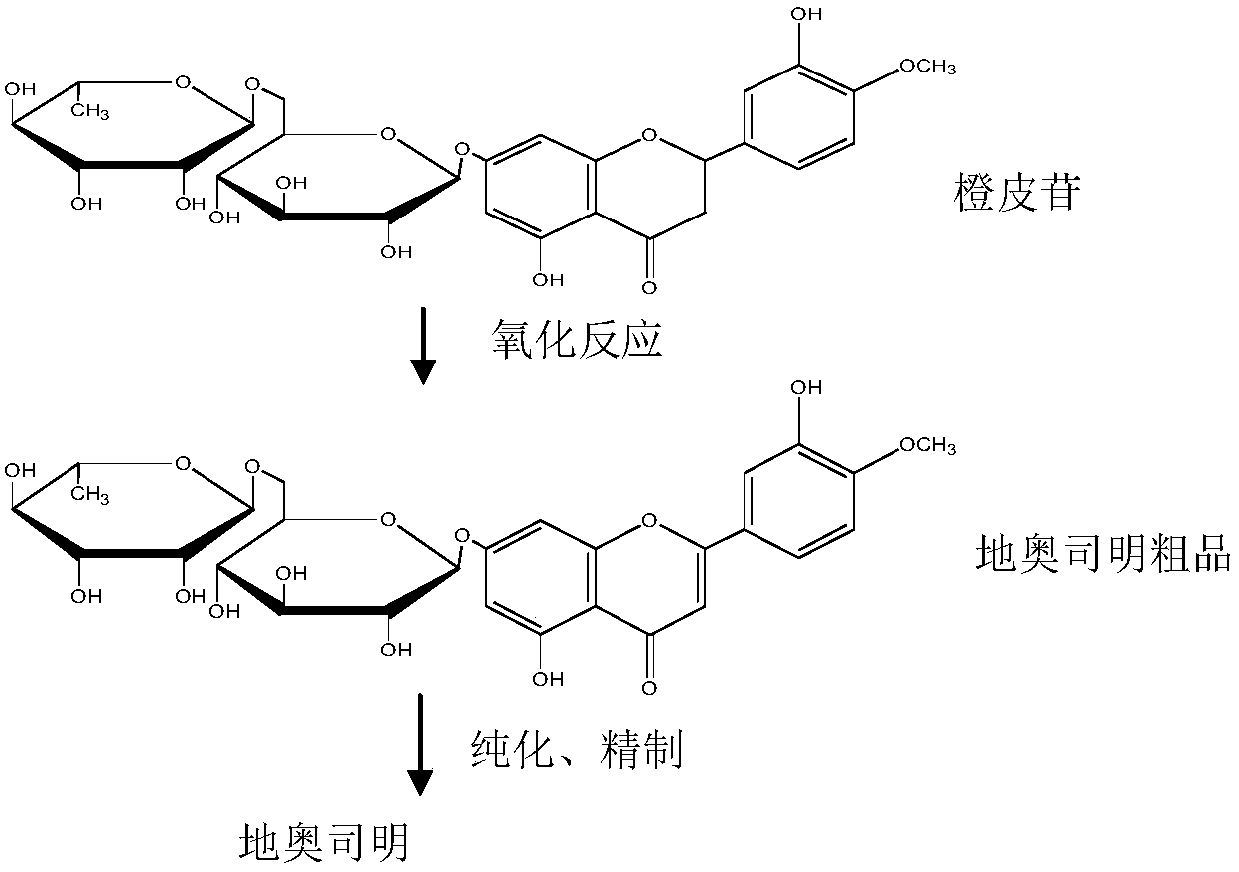

A kind of preparation method of diosmin

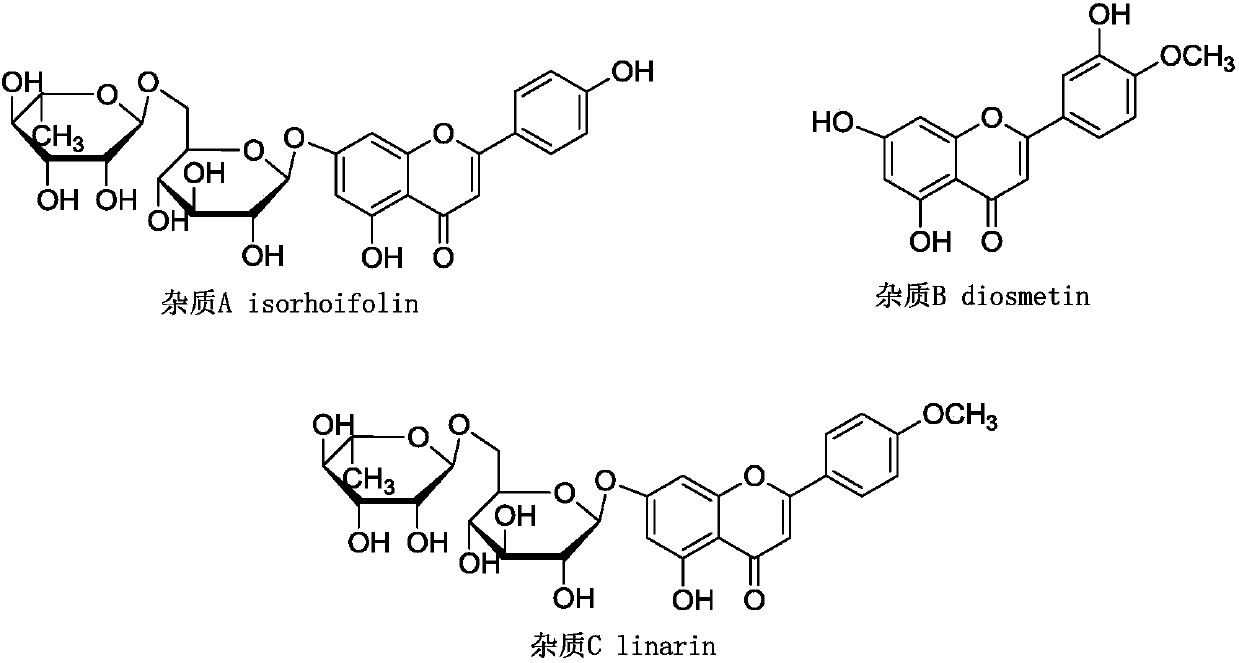

A technology of diosmin and preparation steps, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of difficult recovery of iodine, increase of production costs, and health hazards of operators, and reduce high temperature The effect of impurity content, recovery rate improvement and purity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 2kg of hesperidin and 0.92kg of iodine into a 20L reaction kettle, then add 8L of morpholine, start stirring and raise the temperature, wait until the temperature rises to 40°C and the sample is completely dissolved, keep it at 45°C±5°C for 0.5 hours, then raise the temperature to Insulate and stir at 70°C±5°C for 1.5-3 hours (the complete conversion of hesperidin monitored by HPLC is defined as the end point of the reaction). Recover the solvent until the reactant becomes viscous, add 12L of purified water, stir, stir well, pour the material into the reaction buffer tank, add hydrochloric acid to adjust the pH=5~7 to crystallize, filter to obtain filter cake and filtrate, add hydrochloric acid Adjust the pH of the filtrate to 2, slowly add 0.41 kg of 30% hydrogen peroxide, filter, and recover elemental iodine. The filter cake was washed with a large amount of water to obtain crude diosmin. Add 12L of purified water and 0.39kg of sodium hydroxide into the purificat...

Embodiment 2

[0029] Add 2kg of hesperidin and 0.92kg of iodine into a 20L reaction kettle, then add 10L of N-methylmorpholine, start stirring and raise the temperature. When the temperature rises to 40°C, the sample is completely dissolved, and keep it at 45°C±5°C for 0.5 hours. Then raise the temperature to 80° C.±5° C. and keep stirring for 1.5 to 3 hours (the complete conversion of hesperidin monitored by HPLC is defined as the end point of the reaction). Recover the solvent until the reactant becomes viscous, add 12L of purified water, stir well, pour the material into the reaction buffer tank, add hydrochloric acid to adjust the pH=5~7 for crystallization, filter to obtain filter cake and filtrate, add hydrochloric acid to adjust the filtrate pH = 2, slowly add 0.41 kg of 30% hydrogen peroxide, filter to recover elemental iodine. The filter cake was washed with a large amount of water to obtain crude diosmin. Add 12L of purified water and 0.39kg of sodium hydroxide into the purificat...

Embodiment 3

[0031]Add 2kg of hesperidin and 0.92kg of iodine into a 20L reaction kettle, then add 12L of N,N-diisopropylethylamine, start stirring and raise the temperature, until the temperature rises to 40°C, the sample is completely dissolved, at 45°C±5°C Keep warm for 0.5 hours, then increase the temperature to 80°C±5°C and keep stirring for 1.5 to 3 hours (the complete conversion of hesperidin monitored by HPLC is defined as the end point of the reaction). Recover the solvent until the reactant becomes viscous, add 12L of purified water, stir well, pour the material into the reaction buffer tank, add hydrochloric acid to adjust the pH=5~7 for crystallization, filter to obtain filter cake and filtrate, add hydrochloric acid to adjust the filtrate pH = 2, slowly add 0.41 kg of 30% hydrogen peroxide, filter to recover elemental iodine. The filter cake was washed with a large amount of water to obtain crude diosmin. Add 12L of purified water and 0.39kg of sodium hydroxide into the purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com