A monodisperse nanometer mesoporous silica-titanium dioxide composite sphere and a synthetic method thereof

A nano-mesoporous and silicon dioxide technology, applied in the direction of silicon dioxide, titanium dioxide, silicon oxide, etc., can solve the problems of complex steps, uneven distribution of silicon dioxide and titanium dioxide, long synthesis time, etc., and achieve simple process and high efficiency. Theoretical research and practical application value, the effect of short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Add 73ml of water, 3.0g of CTAB and 12ml of ethanol into the flask and stir vigorously;

[0046] (2) Add 0.4ml triethanolamine to the solution of step (1), and stir for 30min;

[0047] (3) Stir the solution in step (2) and heat up to 60°C, and stir for 30min;

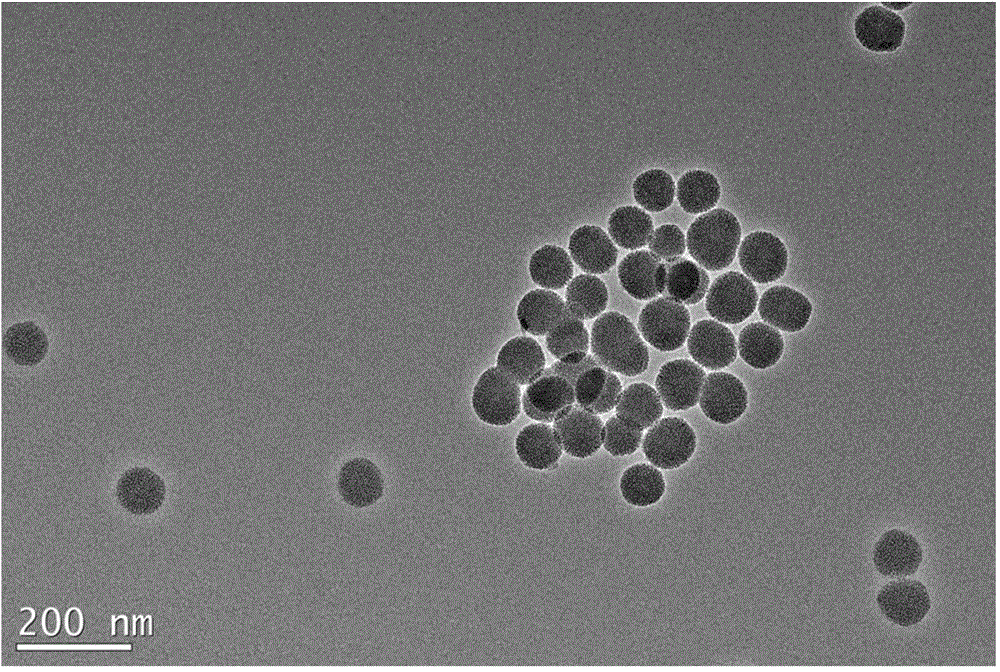

[0048] (4) Add a mixture of 0.385ml tetrabutyl titanate and 7.85ml tetrabutyl orthosilicate dropwise to (3) (tetrabutyl titanate accounts for 5%), stir at the above temperature for 2 hours, and the solution Turned milky white; the obtained product was centrifuged, washed repeatedly with ultrasonic water and alcohol three times; the obtained sample was dried at 25°C for 24 hours to obtain the original powder of nano-mesoporous silica / titanium dioxide balls; the obtained The raw sample powder was burned at 550°C for 5 hours (the heating rate was 1°C / min), and the template agent was removed to obtain a monodisperse nanometer mesoporous silica / titania composite sphere sample. The morphology of the obtained samp...

Embodiment 2

[0050] (1) Add 73ml of water, 6.4gCTAB and 23ml of ethanol into the flask and stir vigorously;

[0051] (2) Add 37.2ml triethanolamine to the solution of step (1), and stir for 10min;

[0052] (3) Stir the solution in step (2) and heat up to 80°C, and stir for 60min;

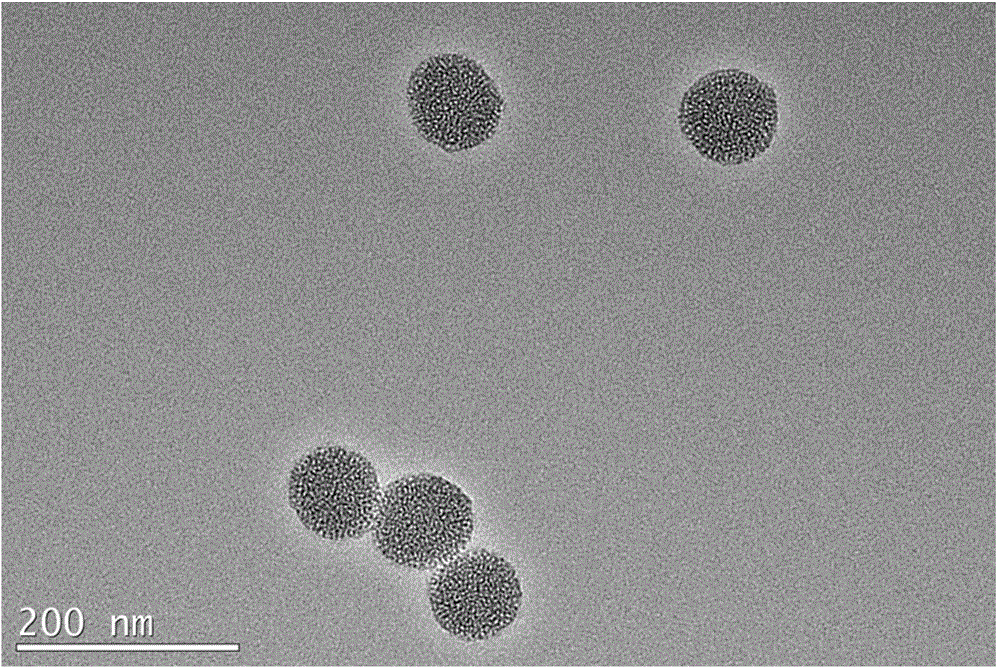

[0053] (4) Add dropwise a mixture of 0.071ml tetrabutyl titanate and 7.85ml tetrabutyl orthosilicate to (3) (tetrabutyl titanate accounts for 1%), stir at the above temperature for 1 hour, and the solution Turned milky white; the obtained product was centrifuged, washed with ultrasonic water and alcohol three times repeatedly; the obtained sample was dried at 60°C for 10 hours to obtain the original powder of nano-mesoporous silica / titanium dioxide balls; the obtained The raw sample powder was burned at 500°C for 10 hours (the heating rate was 3°C / min), and the template agent was removed to obtain a monodisperse nanometer mesoporous silica / titania composite sphere sample. The morphology of the obtained sample ...

Embodiment 3

[0055] (1) Add 73ml of water and 3.0g of CTAB into the flask and stir vigorously;

[0056] (2) Add 0.14ml triethanolamine to the solution of step (1), and stir for 60min;

[0057] (3) Stir the solution in step (2) and heat up to 60°C, and stir for 60min;

[0058] (4) Add dropwise a mixture of 0.84ml tetrabutyl titanate and 7.85ml tetrabutyl orthosilicate (tetrabutyl titanate accounts for 10%) to (3), stir at the above temperature for 3 hours, and the solution Turned into milky white; the obtained product was centrifuged, washed repeatedly with ultrasonic water and alcohol three times; the obtained sample was dried at 40°C for 24 hours to obtain the original powder of nano-mesoporous silica / titanium dioxide balls; the above obtained The raw sample powder was burned at 600°C for 3 hours (the heating rate was 1°C / min), and the template agent was removed to obtain a monodisperse nanometer mesoporous silica / titania composite sphere sample. The morphology of the obtained sample is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com