Glass fiber reinforced molded plastic internal thread end cover compression mold

A glass fiber and reinforced mold technology, which is applied in the field of compression molds for glass fiber reinforced molding plastic internal thread end caps, can solve problems such as difficult exhaust, and achieve the effects of difficult exhaust, convenient operation, and high-efficiency compression molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

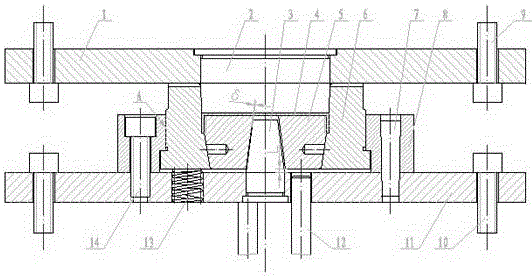

[0021] The device includes an upper template 1, a punch 2, a central rod 3, a threaded mold core 5, a die 6, 3 tapered pins 7, a die sleeve 8, 10 upper template fixing screws 9, 10 lower template fixing screws 10, Lower template 11, 3 ejector rods 12, 3 cylindrical helical compression springs 13, 3 mold cover fixing screws 14, such as figure 1 shown. Described punch 2, die 6, screw core 5 and central rod 3 form the closed cavity of end cap product 4, as figure 1 shown.

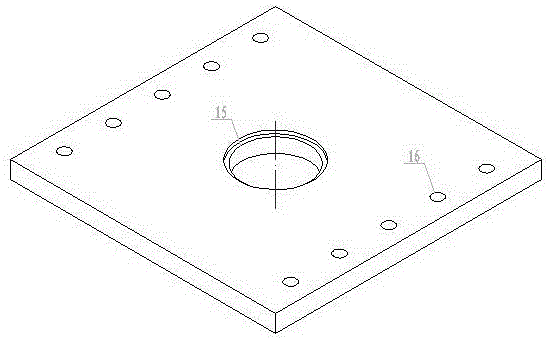

[0022] Described upper template 1 is provided with the hole 15 of fixed punch 2, 10 through holes 16 that upper template fixing screw 9 is installed, as figure 2 shown.

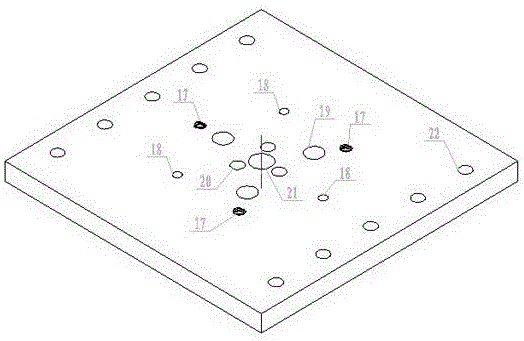

[0023] The lower template 11 is provided with three threaded holes 17 for mounting screws 14, three conical pin holes 18, three through holes 19 for placing cylindrical helical compression springs 13, three through holes 20 for placing ejector rods 12, Fix the holes 21, 10 through holes 22 of the lower formwork fixing screws 10 for fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com