Grinding wheel for polishing and grinding ceramic tile biscuit, manufacturing method of grinding wheel and polishing and grinding apparatus and polishing and grinding method for ceramic tile biscuit

A technology for green tiles and ceramic tiles, which is applied in the field of grinding wheels for polishing tile green tiles and its manufacture. It can solve the problems of grinding heat effect between the surface of the grinding wheel and the surface of tile green tiles, the effect of air cooling is not very ideal, and reduce the production cost of tiles. Improved cooling effect, improved chip removal performance, and reduced replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention mainly improves the structure of the grinding wheel in the ceramic tile blank polishing device to reduce the missing polishing rate. The structure of other parts of the ceramic tile blank polishing device can be designed according to existing products. In addition, the mandrel structure of the grinding wheel for polishing and polishing ceramic tiles is adaptively designed according to the frame structure of the polishing and polishing device, and is not limited to the following embodiments.

[0038] The first embodiment of the grinding wheel for polishing and polishing ceramic tile

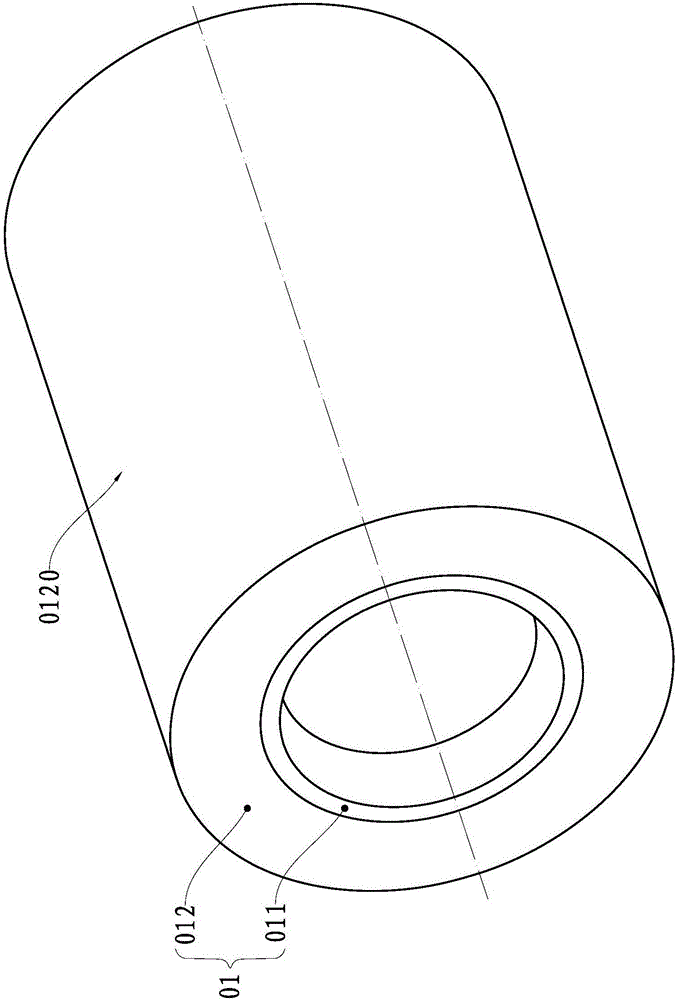

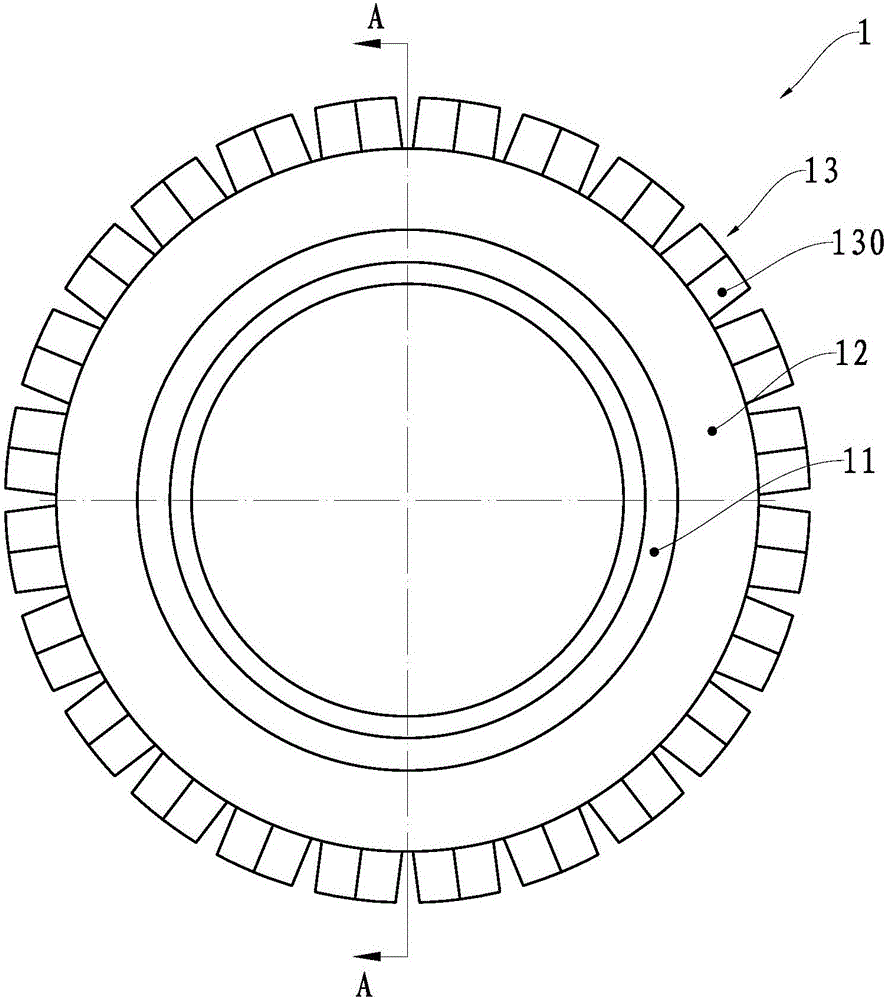

[0039] See Figure 2 to Figure 4 , The grinding wheel 1 for ceramic tile blank polishing is composed of a mandrel 11, a cylindrical elastic layer 12 and a grinding layer 13. The grinding layer 13 is arranged in a direction parallel to the rotation axis 02 of the ceramic tile blank polishing wheel 1 The rotation axis 02 is the axis around which the grinding wheel 1 for poli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com