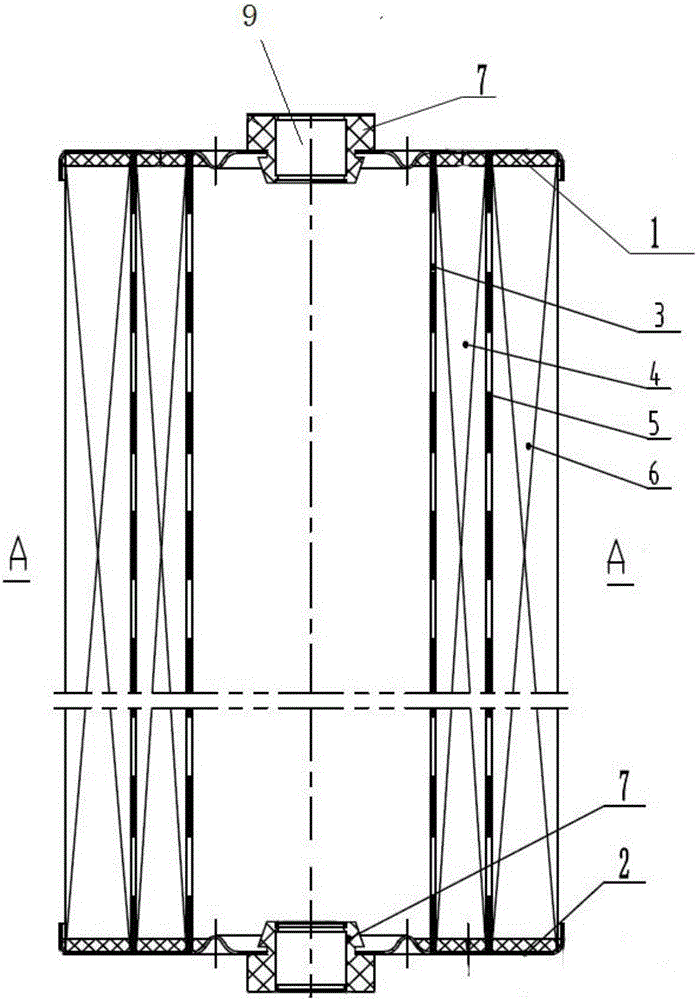

Two-stage integrated composite filter element for oil product filtering

A composite filter element and oil technology, applied in filtration and separation, filtration circuits, chemical instruments and methods, etc., can solve the problems of poor filtration function and indicators, difficult to popularize practically, and complicated film production process, and achieve improved performance. Toughness and strength, overcoming broken wires, high filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

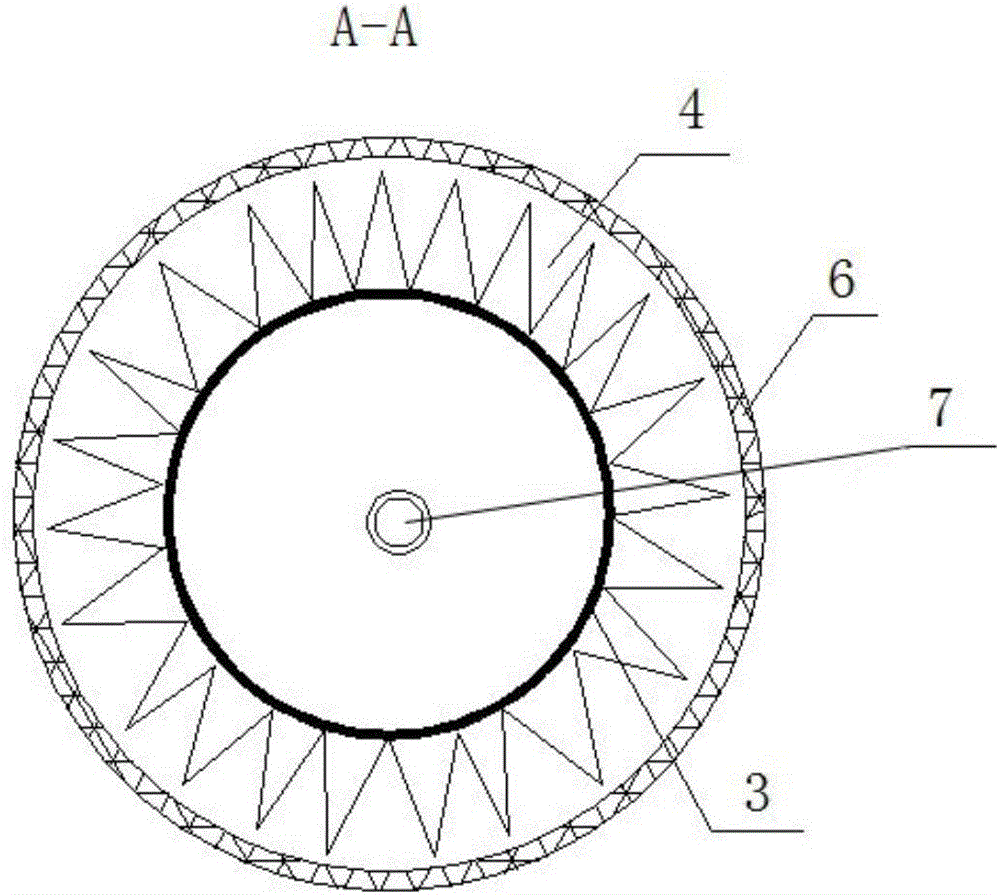

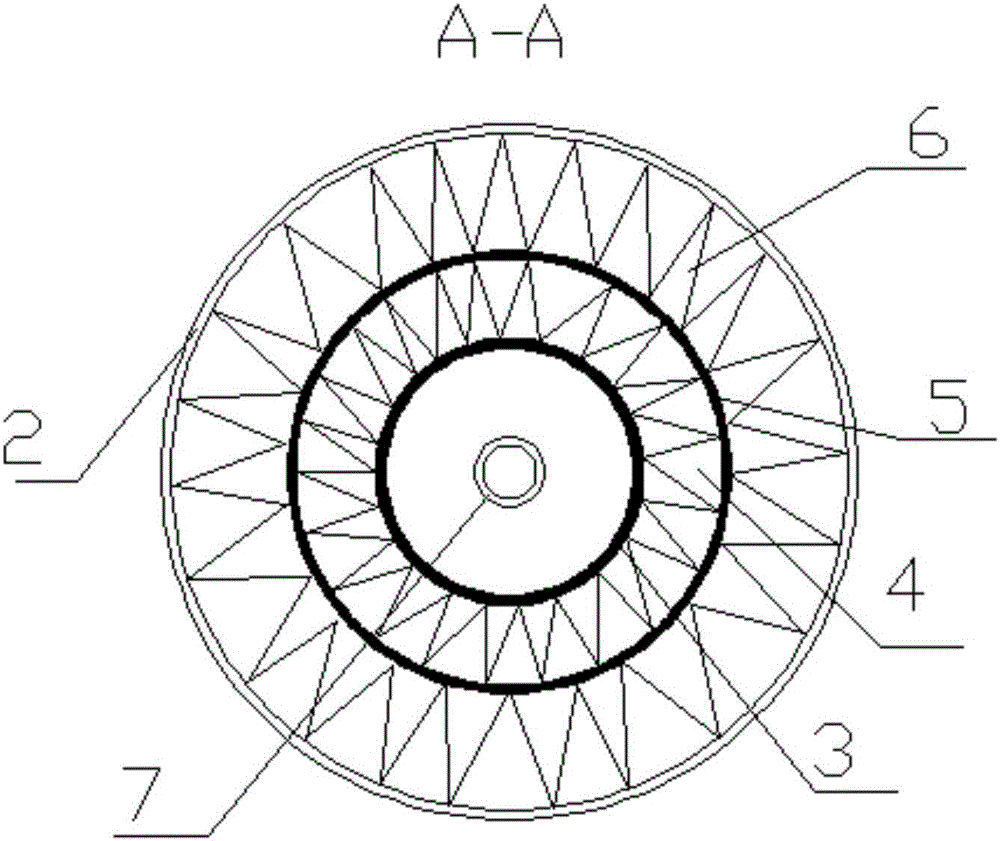

Method used

Image

Examples

Embodiment 1

[0058] Example 1: The material of polyamide melt-blown non-woven fabric is PA6, and after processing such as folding and nesting with the composite filter paper, the length of the cylindrical filter element made is 200 mm, and the outer diameter is 100 mm. The polyamide melt-blown non-woven fabric The thickness is 0.3mm, the average pore diameter of the polyamide melt-blown non-woven fabric is 10 μm, the average diameter of the melt-blown non-woven fiber filament is 0.1 μm, and the porosity is 98.2%; The type of oil is gasoline; the filtration effect of pleated non-woven fabric and pleated filter paper applied to gasoline filters: the filtration efficiency of 5-10μm particles is 98.12%; the dirt holding capacity is 60.85g, and when the rated volume flow rate is 10L / min, The original circulation resistance is 11.20kpa, and the oil-water separation rate is 98.25%.

Embodiment 2

[0059] Example 2: The material of polyamide melt-blown non-woven fabric is PA6, and after being folded and nested with the composite filter paper, the length of the cylindrical filter element is 200 mm, and the outer diameter is 100 mm. Polyamide melt-blown non-woven fabric The thickness of the polyamide melt-blown non-woven fabric is 1.5mm, the average pore diameter of the polyamide melt-blown non-woven fabric is 100 μm, the average diameter of the melt-blown non-woven fiber filament is 80 μm, and the porosity is 91.2%; the average pore diameter of the composite filter paper is 50 μm, and the thickness is 1.5mm; The type of filter oil is lubricating oil; pleated non-woven fabric and pleated filter paper are applied to the filter effect of the oil filter: the filtration efficiency of 5-10μm particles is 92.95%; the dirt holding capacity is 125.99g, and the rated volume flow rate is 10L / min , the original flow resistance is 12.55kpa, and the oil-water separation rate is 91.98%. ...

Embodiment 3

[0060] Example 3: The material is PA66; the polyamide melt-blown non-woven fabric material is PA6, and after processing such as folding and nesting with the composite filter paper, the length of the cylindrical filter element made is 200mm, and the outer diameter is 100mm, polyamide melt-blown The thickness of the non-woven fabric is 1 mm, the average pore diameter of the polyamide melt-blown non-woven fabric is 100 μm, the average diameter of the melt-blown non-woven fiber filament is 25 μm, and the porosity is 90.2%; the average pore diameter of the composite filter paper is 30 μm, and the thickness is 0.5 mm; the filter oil type is lubricating oil; the filter effect of pleated non-woven fabric and pleated filter paper applied to the oil filter: the filtration efficiency of 5-10μm particles is 92.75%; the dirt holding capacity is 102.33g, and the rated volume flow rate is 10L / min, the original flow resistance is 12.05kpa, and the oil-water separation rate is 91.23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com