Method for preparing lyophilized donkey milk powder by low temperature sterilization

A donkey milk powder and donkey milk technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of large loss of nutrients, milk powder solubility, poor reconstitution, low qualified donkey milk powder, etc., and achieve a high yield Excellent lifting, rehydrating and instant dissolving properties, filling the gap in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

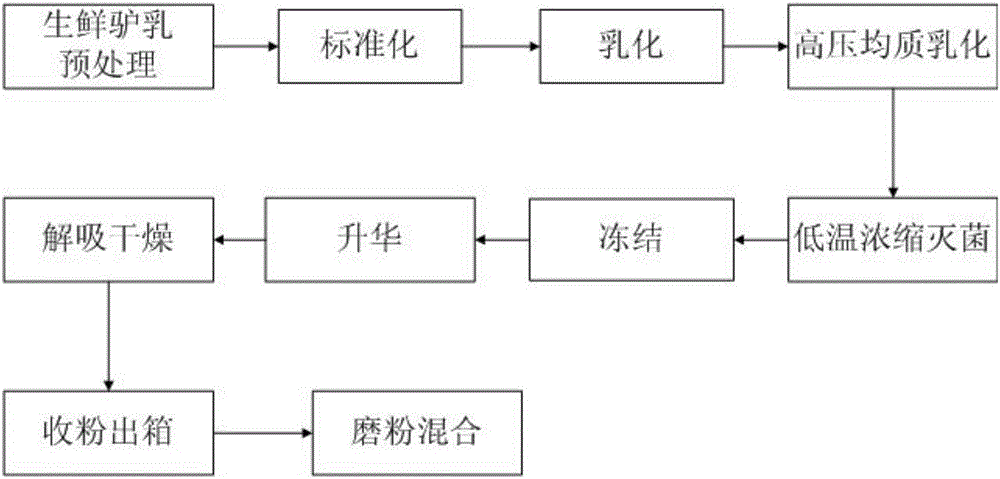

Image

Examples

Embodiment 1

[0024] Embodiment 1: A method for preparing freeze-dried donkey milk powder by low-temperature sterilization, comprising the steps of:

[0025] The first step is pretreatment of fresh donkey milk: Filter the qualified fresh donkey milk through a 100-200 mesh nylon gauze and then move it to the refrigeration equipment for refrigeration. The temperature is controlled at -1°C to -5°C, and the storage time does not exceed 48 Hour;

[0026] The second step of standardization: use donkey fat to adjust the fat content in fresh donkey milk to ≥0.7%;

[0027] The third step of emulsification: adjust the gap between the stator and rotor of the colloid mill to 0.05㎜~0.3㎜, add the qualified fresh donkey milk into the colloid mill for emulsification and mixing, control the particle size of fat globules to ≤0.15㎜, and the degree of emulsification to ≥95%;

[0028] The fourth step is high-pressure homogeneous emulsification: add the emulsified liquid donkey milk to a high-pressure homogeniz...

Embodiment 2

[0036] Embodiment 2: a method for preparing freeze-dried donkey milk powder by low-temperature sterilization, comprising the following steps:

[0037] The first step is pretreatment of fresh donkey milk: Filter the qualified fresh donkey milk through a 100-200 mesh nylon gauze and then move it to the refrigeration equipment for refrigeration. The temperature is controlled at -1°C to -5°C, and the storage time does not exceed 48 Hour;

[0038] The second step of standardization: use donkey fat to adjust the fat content in fresh donkey milk to ≥0.7%;

[0039] The third step of emulsification: adjust the gap between the stator and rotor of the colloid mill to 0.05㎜~0.3㎜, add the qualified fresh donkey milk into the colloid mill for emulsification and mixing, control the particle size of fat globules to ≤0.15㎜, and the degree of emulsification to ≥95%;

[0040] The fourth step is high-pressure homogeneous emulsification: add the emulsified liquid donkey milk into a high-pressure ...

Embodiment 3

[0048] Embodiment 3: a method for preparing freeze-dried donkey milk powder by low-temperature sterilization, comprising the following steps:

[0049] The first step is pretreatment of fresh donkey milk: Filter the qualified fresh donkey milk through a 100-200 mesh nylon gauze and then move it to the refrigeration equipment for refrigeration. The temperature is controlled at -1°C to -5°C, and the storage time does not exceed 48 Hour;

[0050] The second step of standardization: use donkey fat to adjust the fat content in fresh donkey milk to ≥0.7%;

[0051] The third step of emulsification: adjust the gap between the stator and rotor of the colloid mill to 0.05㎜~0.3㎜, add the qualified fresh donkey milk into the colloid mill for emulsification and mixing, control the particle size of fat globules to ≤0.15㎜, and the degree of emulsification to ≥95%;

[0052] The fourth step is high-pressure homogeneous emulsification: add the emulsified liquid donkey milk into a high-pressure ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com