Method for preparing circuit board

A circuit board and metal pattern technology, applied in printed circuit manufacturing, printed circuit, printed circuit secondary processing, etc., can solve the problems of expensive super-roughening syrup, inability to prepare circuit boards, and limiting the wide production of RO3003 mixed-pressed sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

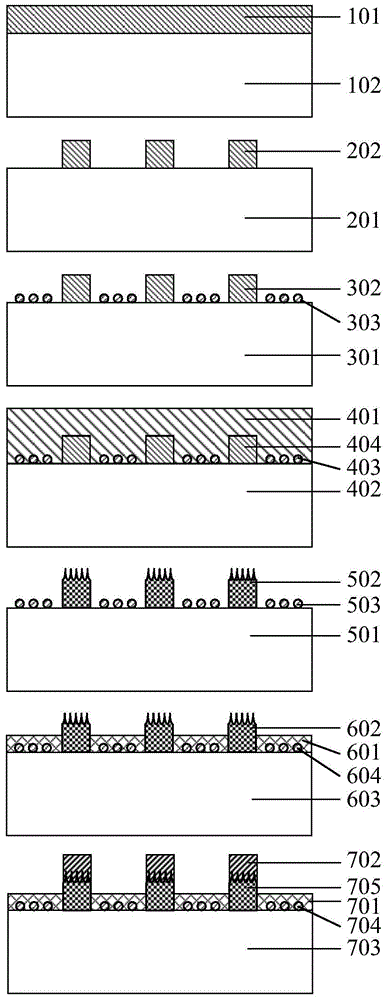

[0027] like figure 1 As shown, the method for preparing a circuit board according to an embodiment of the present invention includes: step 102, forming a first metal layer on the circuit board lamination layer; step 104, patterning the first metal layer to form The first metal pattern layer; step 106, performing plasma cleaning on the circuit board lamination layer and the first metal pattern layer; step 108, forming a solder mask on the circuit board lamination layer after plasma cleaning Structure; step 110, after forming the solder resist structure, forming a second metal pattern layer on the first metal pattern layer.

[0028] In this technical solution, by performing plasma cleaning on the circuit board lamination layer and the first metal pattern layer, the roughness of the circuit board lamination layer is enhanced, the possibility of peeling off of the solder resist structure is reduced, and The risk of gold penetration on the circuit board improves the reliability of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com