Heat exchanger structure

A heat exchanger and medium technology, applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve the problems of flat tube failure, heat exchanger leakage failure, etc., to eliminate thermal stress, avoid failure, The effect of preventing leakage failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

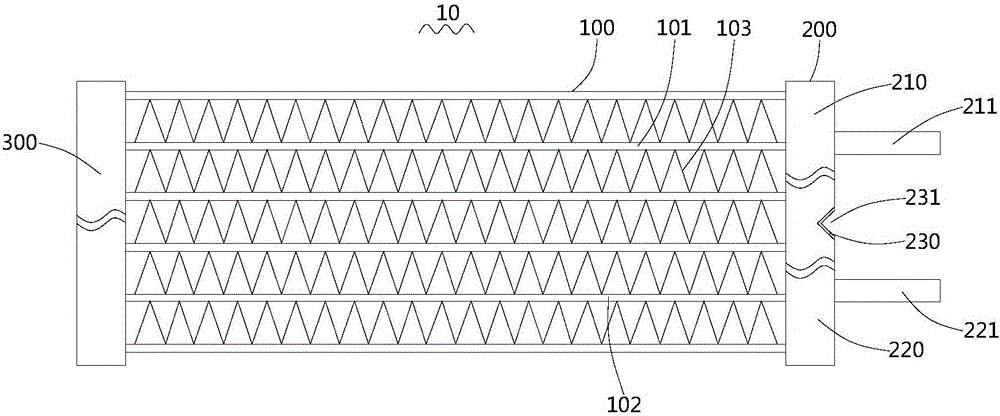

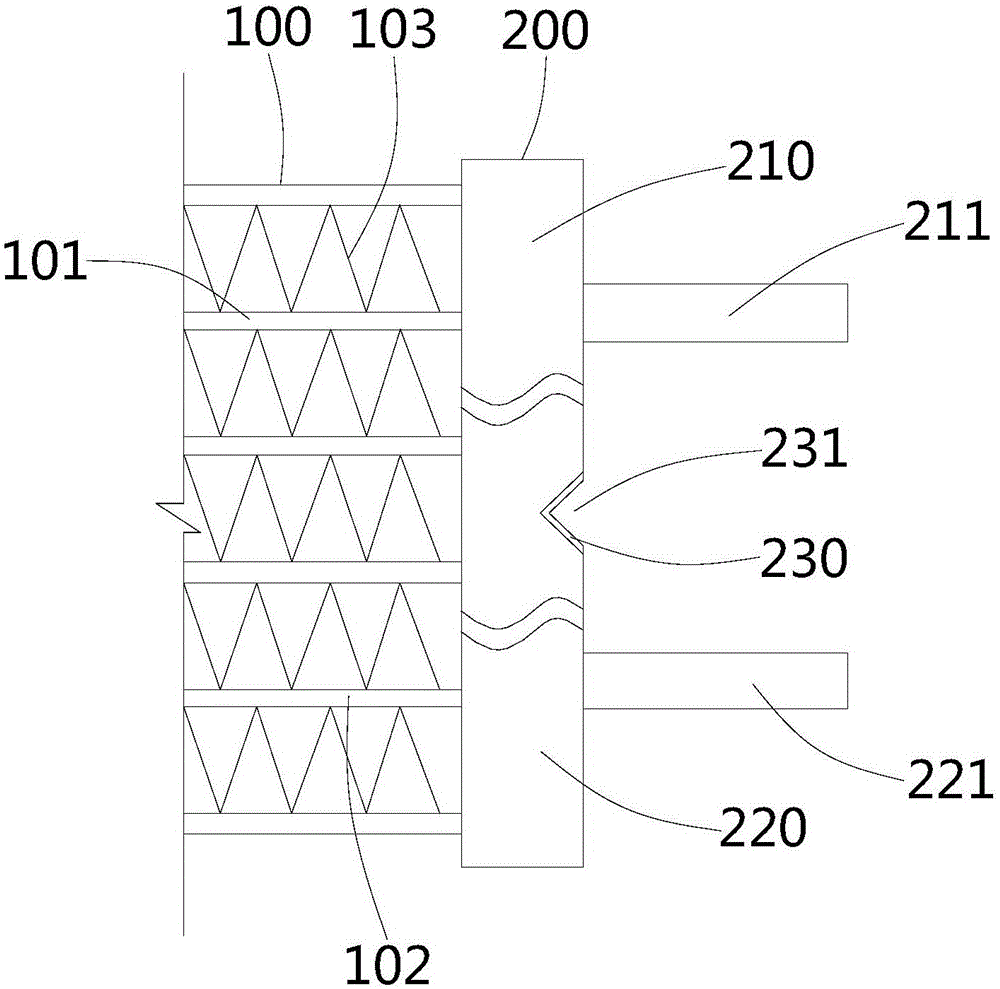

[0038] figure 1 A schematic diagram of the overall structure of the heat exchanger structure 10 provided by the embodiment of the present invention; figure 2 A schematic diagram of the local structure at the first header 200 of the heat exchanger structure 10 provided by the embodiment of the present invention; please refer to figure 1 and figure 2 , the present embodiment provides a heat exchanger structure 10 , and the heat exchanger structure 10 includes a heat exchanger body 100 , a first header 200 and a second header 300 .

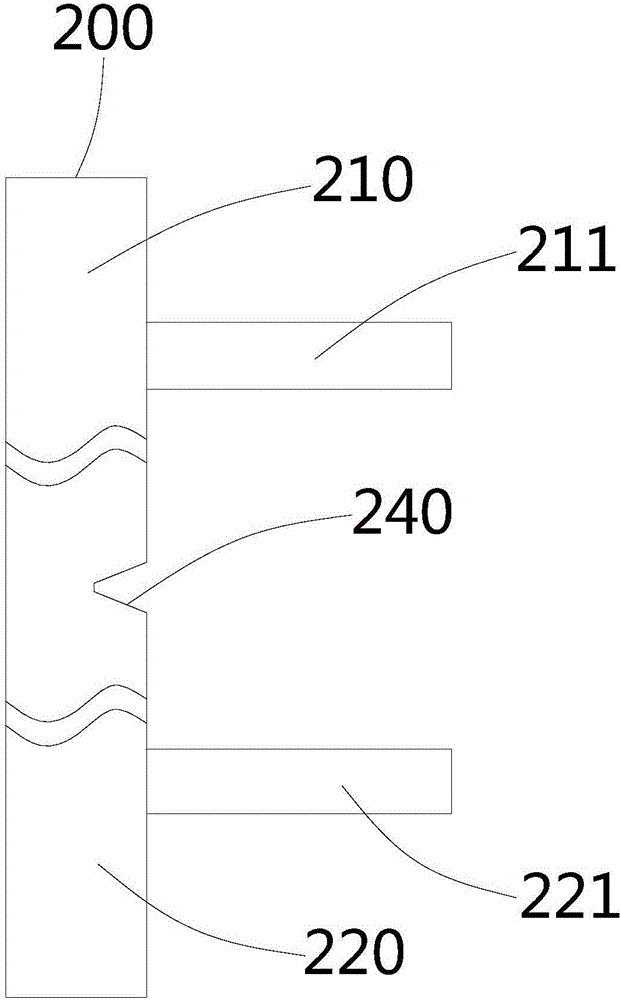

[0039] The first header 200 is provided with a medium inflow portion 210 , a medium outflow portion 220 and a separator 230 . The medium inflow part 210 is provided with an inlet 211 , and the medium outflow part 220 is provided with an outlet 221 . A plurality of first pipes 101 and a plurality of second pipes 102 are arranged on the heat exchanger body 100 . One end of the first pipe 101 communicates with the medium inflow portion 210 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com