High-voltage solid heat storage equipment and heat storage control method

A solid heat storage, high voltage technology, applied in heat storage equipment, lighting and heating equipment, electric heating devices, etc., can solve the problems of poor reliability, high failure rate, large leakage current, etc., to avoid high temperature damage and high measurement accuracy , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

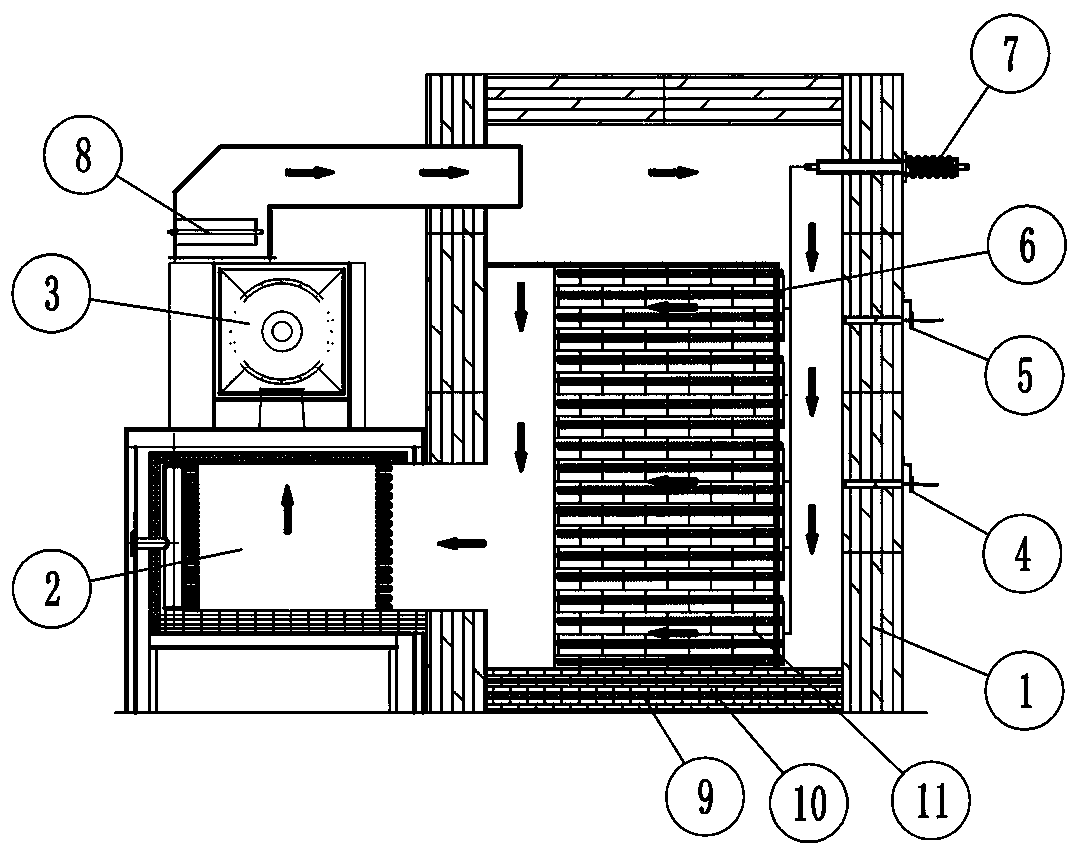

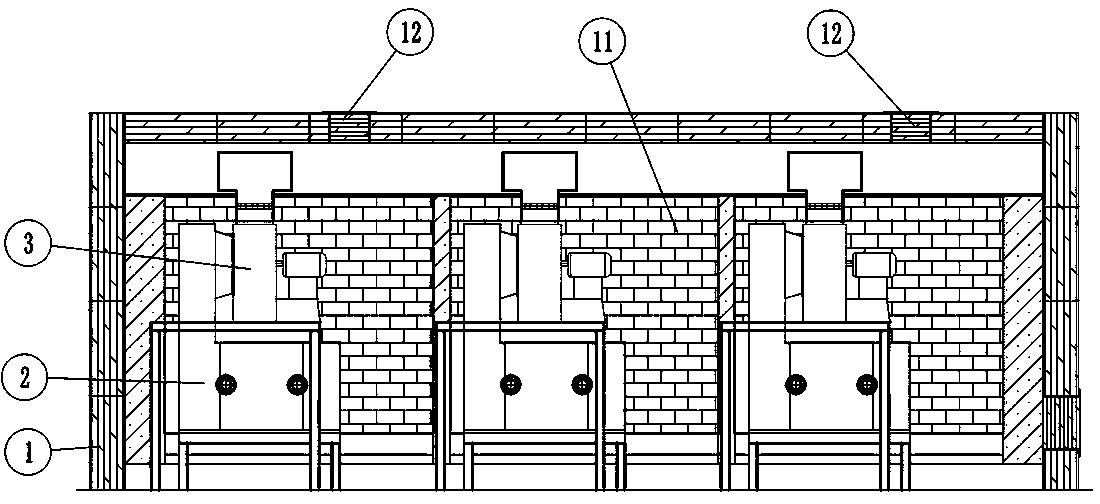

[0032] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0033] Such as figure 1 with 2 , high-voltage solid heat storage equipment, including heat storage modules and heat exchange modules;

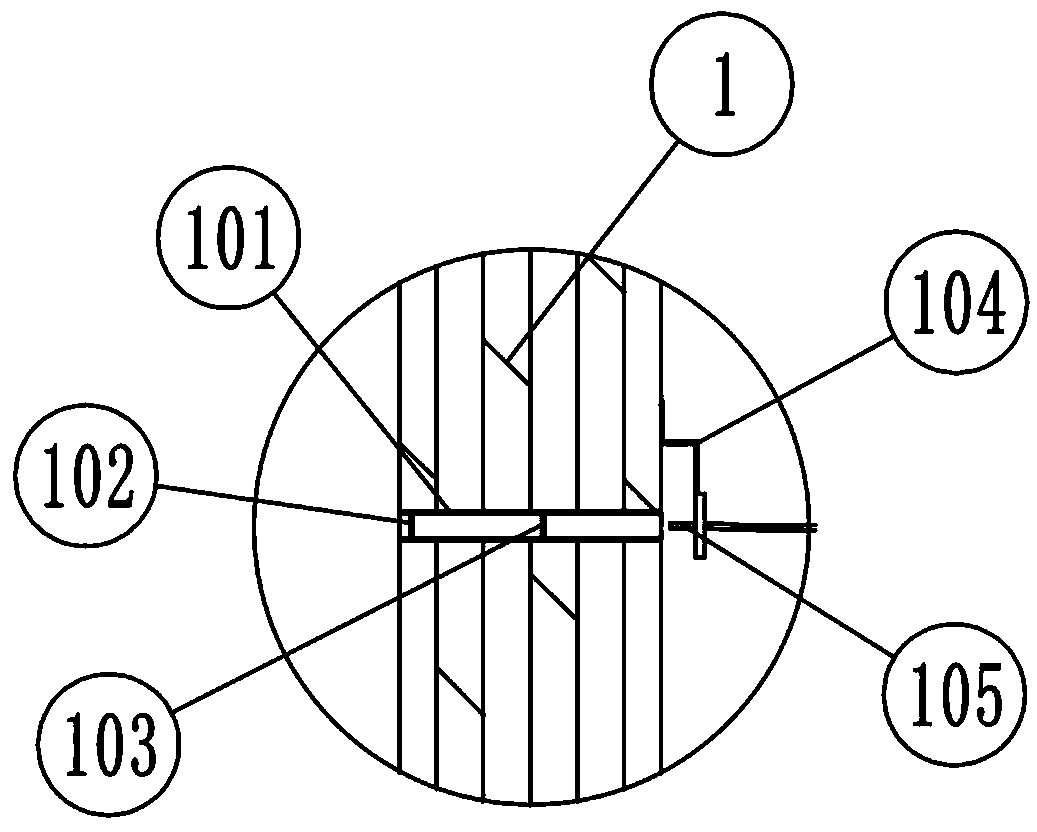

[0034] The heat storage module includes a heat storage body composed of heat storage bricks 11, a heat insulating layer arranged on the periphery of the heat storage body, and a heating wire assembly passing through the heat storage body, and the heating wire assembly is used to heat the heat storage body; The heating wire assembly is connected with the power supply device for power supply heat storage equipment through the high-voltage ceramic joint 7;

[0035] The thermal insulation layer is spliced by several ceramic fiber cotton thermal insulation modules 1, which effectively solves the problems of complex external thermal insulation structure and long construction period of the heat storage body;

[0036] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com