Heat pump air conditioning and heating and cooling methods based on methanol water reforming hydrogen production power generation system

A technology for reforming hydrogen production and power generation systems, applied in heating and cooling combinations, refrigerators, refrigeration components, etc., can solve problems such as energy loss, increased maintenance costs, and reduced heat pump efficiency, and achieve the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

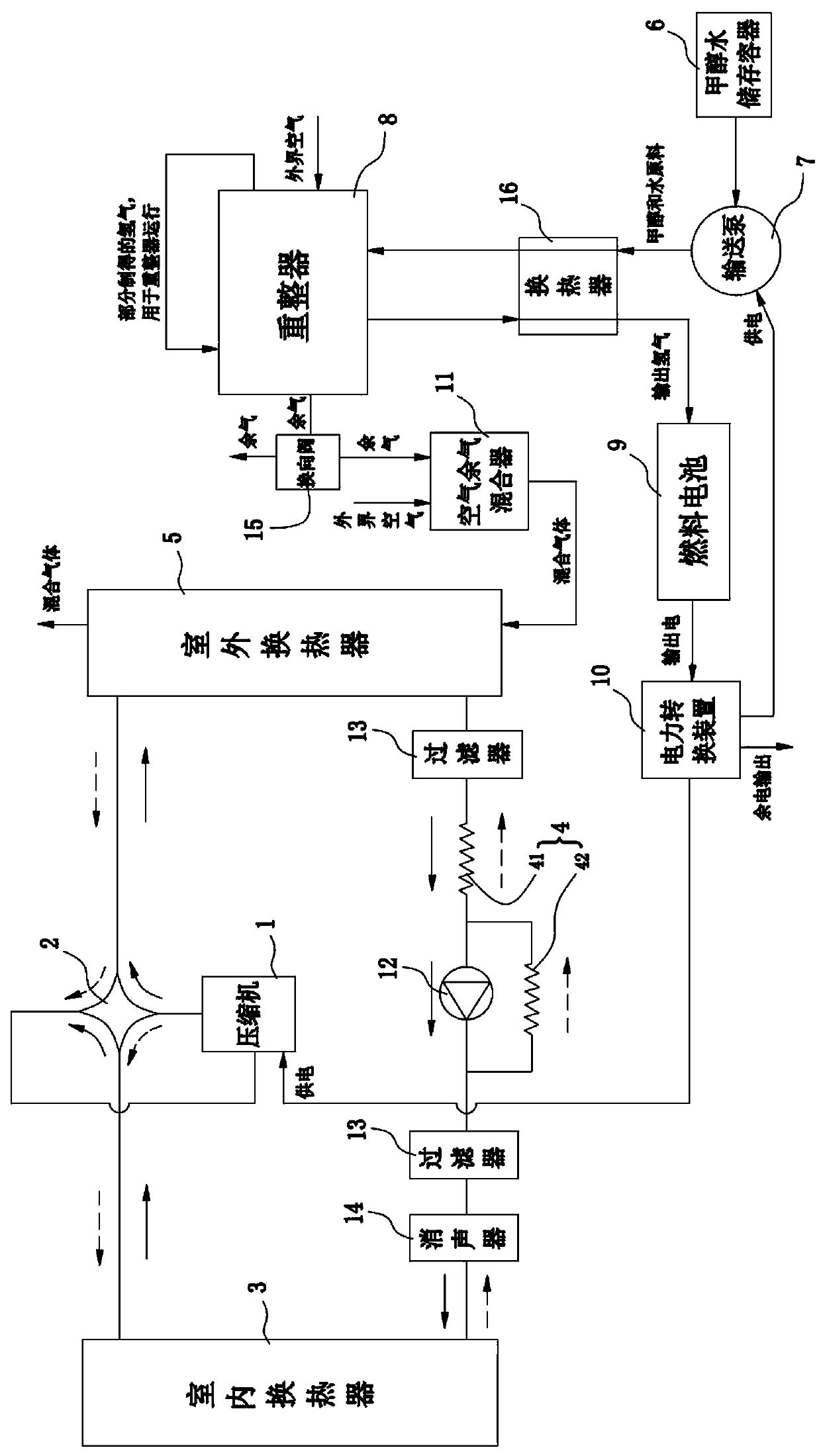

[0019] Such as figure 1 As shown, a heat pump air conditioner based on methanol water reforming hydrogen production power generation system includes compressor 1, four-way reversing valve 2, indoor heat exchanger 3, throttle valve 4, outdoor heat exchanger 5, methanol water storage Container 6, transfer pump 7, reformer 8, fuel cell 9, power conversion device 10 and residual air mixer 11; the compressor 1, four-way reversing valve 2, indoor heat exchanger 3, throttle valve 4 and the outdoor heat exchanger 5 form the working fluid delivery circuit of the heat pump air conditioner. figure 1 In the working fluid delivery circuit, the dotted arrow indicates the heating condition, and the solid arrow indicates the cooling condition; the methanol-water storage container 6 stores liquid methanol-water raw material; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com