An energy collection system integrating solar photovoltaic light and heat

A solar photovoltaic and energy collection technology, applied in the field of energy collection systems, can solve the problems of complex equipment structure, high cost, and high water temperature, and achieve the effects of improved conversion capacity/efficiency, reduced heat loss, and high heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1. Material preparation

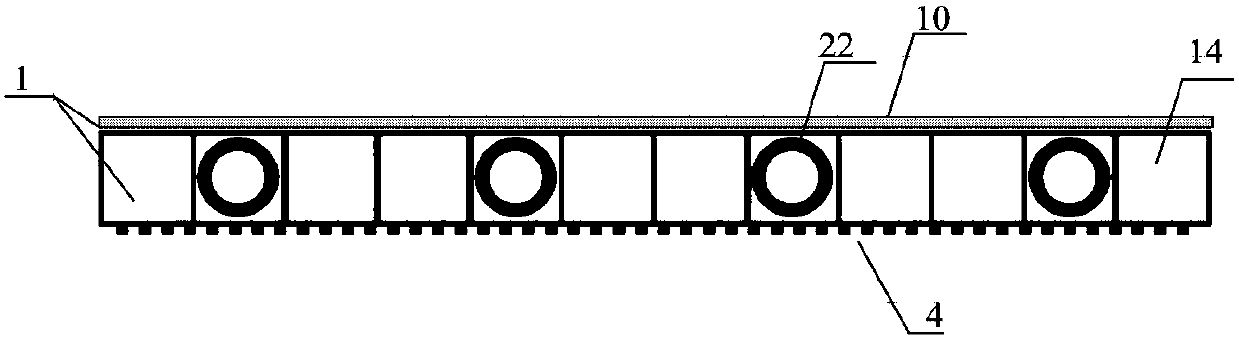

[0060] 1. The specification of the heat collecting unit is set to 600*1200mm, so the thickness of the hollow heat collecting plate with channel is set to 5mm, the channel cross-sectional area of the internal grid is 5*5mm, and the material of the heat collecting plate is transparent PC carbonate hollow plate .

[0061] 2. The outer diameter of the plastic pipe used as the branch pipe is set to 4mm, and the wall thickness is 1mm. The outer diameter of the distribution / collection pipe used as the first main pipe and the second main pipe is set to 20mm, and the wall thickness is 2mm. The plastic pipe material It is PE-RT with various additives, and the color is set to carbon black.

[0062] 2. Making heat collecting plate

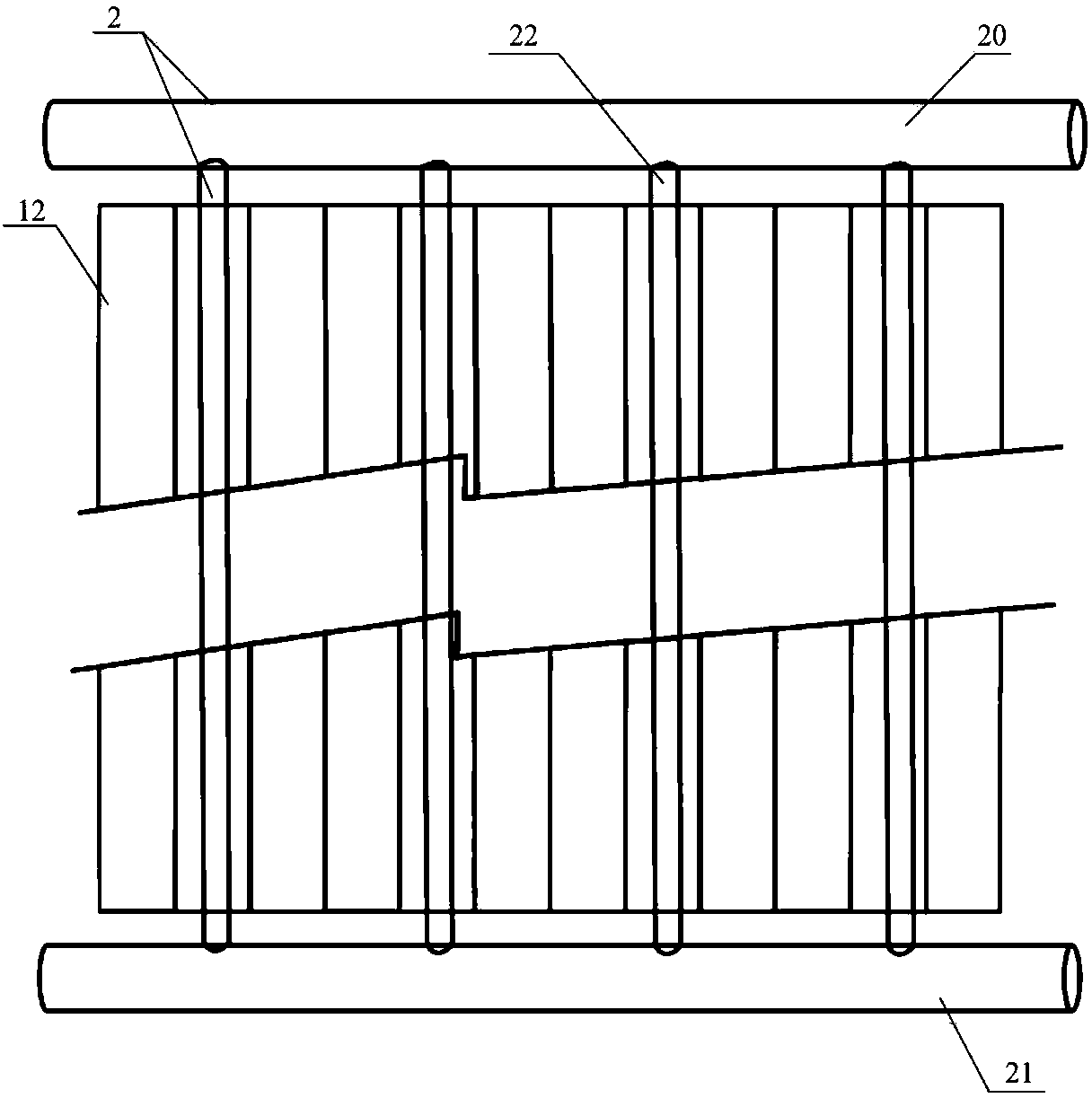

[0063] The distance between the plastic pipes used as branch pipes is set to 20mm, occupying a channel of a hollow heat collecting plate every 20mm, and then welding the two ends to the first dry pipe and the second dry pip...

Embodiment 2

[0067] 1. Material preparation

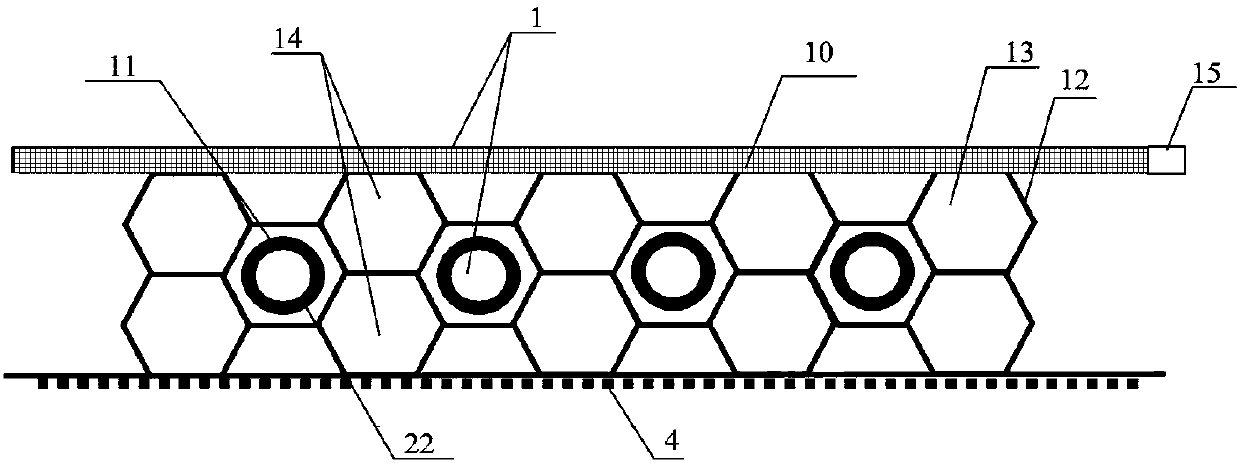

[0068] 1. The specification of the heat collecting unit is set to 1000*2000mm, so the thickness of the hollow heat collecting plate with channels is set to 18mm, and the middle channel is in the shape of three layers of honeycomb, so that each grid channel can accommodate 6mm plastic pipes to penetrate and collect heat. The board material is transparent PC carbonate hollow board.

[0069] 2. The outer diameter of the plastic pipe used as the branch pipe is set to 6mm, and the wall thickness is 1.2mm. The tube material is PE-RT with various additives, and the color is set to carbon black.

[0070] 2. Making heat collecting plate

[0071] The distance between the plastic pipes used as branch pipes is set to 20mm, and every 20mm occupies a channel in the middle layer of a hollow heat collector plate, and then welds its two ends to the first dry pipe and the second dry pipe respectively to form a collector In the heat unit, the two ends of the f...

Embodiment 3

[0075] 1. Material preparation

[0076] Such as Figure 5 As shown, the heat collecting plate in the heat collecting unit is replaced by heat collecting fins 6 with multiple longitudinally distributed arc grooves 60 inside, the specification of which is set to 600*1200mm, and the cross-sectional area of the arc groove is set It is 5*5mm, and the heat collecting fin material is transparent PC carbonate polyester.

[0077] 2. The outer diameter of the plastic pipe used as the branch pipe is set to 4mm, and the wall thickness is 1mm. The outer diameter of the distribution / collection pipe used as the first main pipe and the second main pipe is set to 20mm, and the wall thickness is 2mm. The plastic pipe material It is PE-RT with various additives, and the color is set to carbon black.

[0078] 2. Making heat collecting plate

[0079] The distance between the plastic pipes used as the branch pipes 22 is set to 20mm, occupying a channel of a hollow heat collecting plate every 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com