Installation and leveling method of external thermal insulation cement decorative panel with flexible sealing joint

A technology for decorative panels and external thermal insulation of exterior walls, applied in covering/lining, construction, building construction, etc., can solve problems such as limited artistic expression of decorative surfaces, inconsistency of decorative patterns, increased construction labor costs, etc., to achieve a wider decorative The effects of surface expression range, shortening the construction period, and saving construction labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

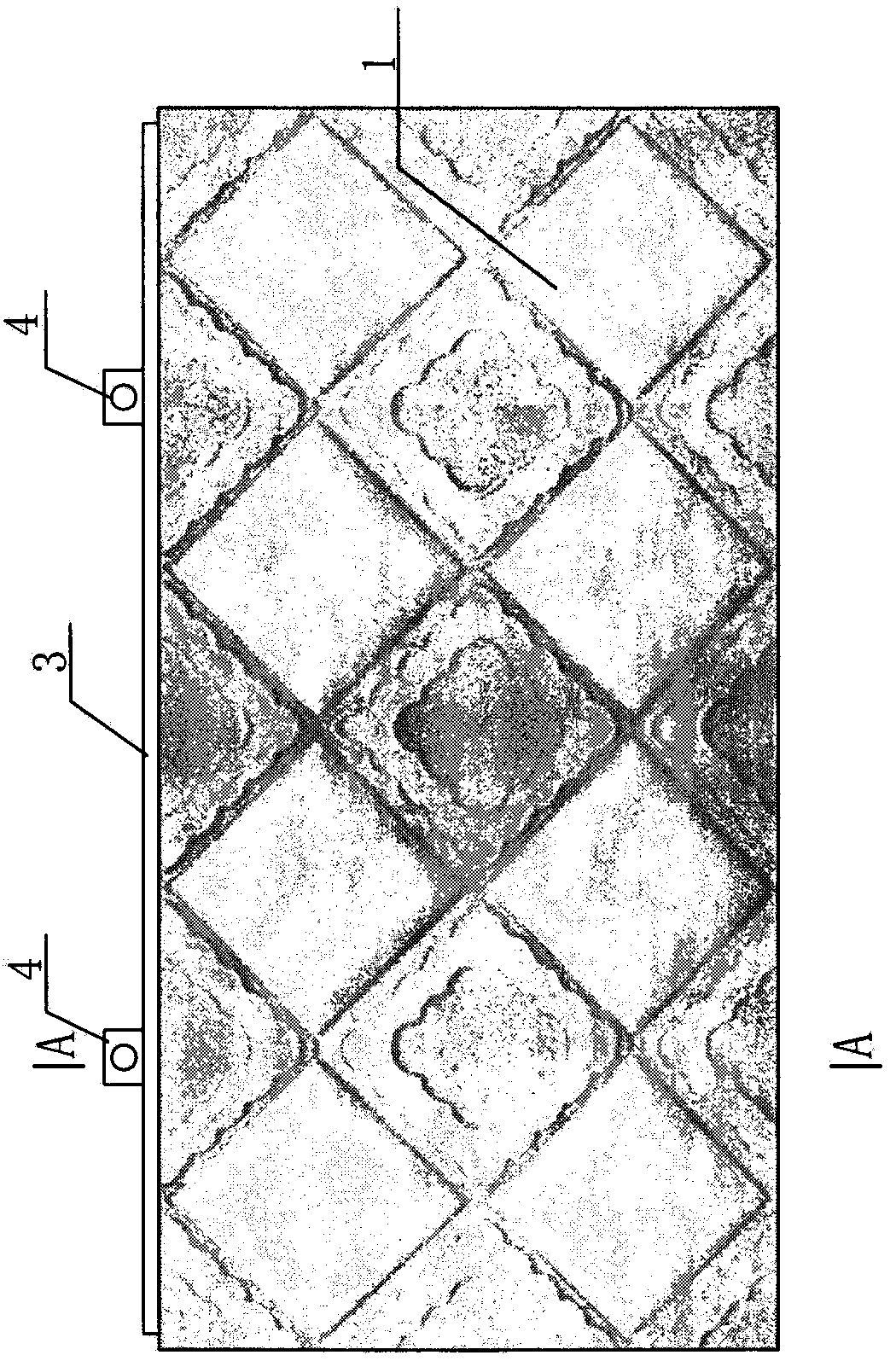

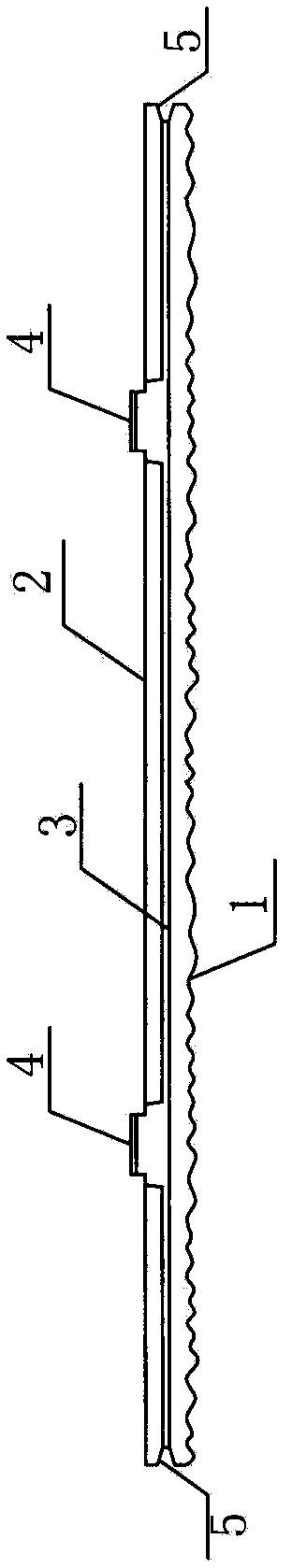

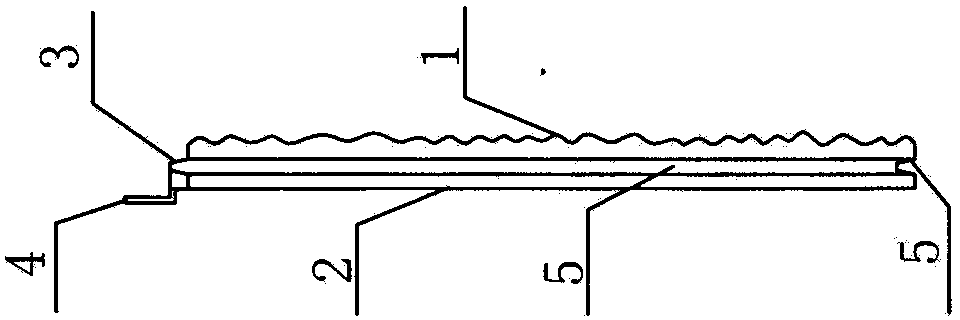

[0042] Such as Figure 1-Figure 17 Shown is a cement decorative panel for external heat preservation of external walls, with metal or non-metallic mesh 10 inside, three-dimensional decorative patterns 1 prefabricated on the outer surface, the inner surface 2 is a plane, and the upper end surface is provided with a long convex key 3, and Metal pendants 4 are arranged at a certain interval, and grooves 5 are provided on the lower end surface and the end surfaces on both sides; when the cement decorative panel is constructed and assembled, the method of horizontal seam is: the lower end surface of the upper row of panels is superimposed on the upper surface of the next row of panels The long protruding key 3 on the upper surface of the upper and lower row of boards is embedded in the groove 5 of the lower end surface of the upper row of boards to form a hidden key joint 6; Filled with sealant 8, after the boards are facing tightly and anchored in place, insert a metal or plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com