Blowing and suction work device for rail suction-type sewer scavenger

The technology of a working device and a sewage suction vehicle is applied in the directions of rail cleaning, construction, cleaning methods, etc., which can solve the problems of dust and iron filings pollution on the ballast bed, and achieve the effect of reasonable airflow direction, avoiding large-scale dust, and improving the blowing and suction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

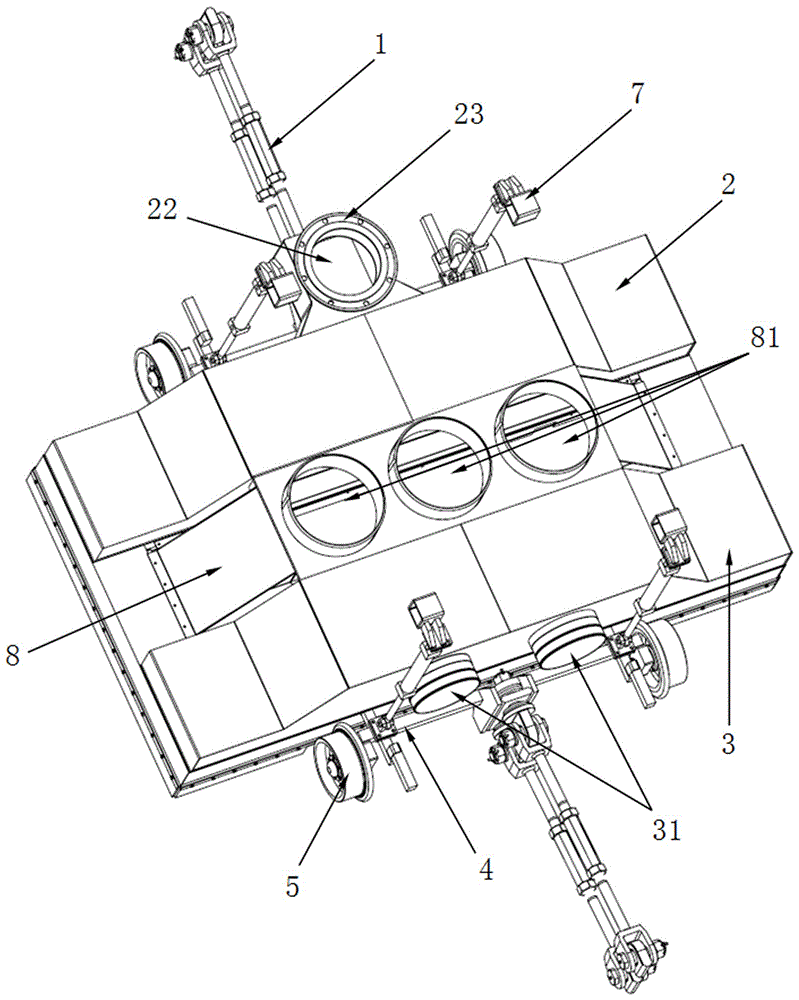

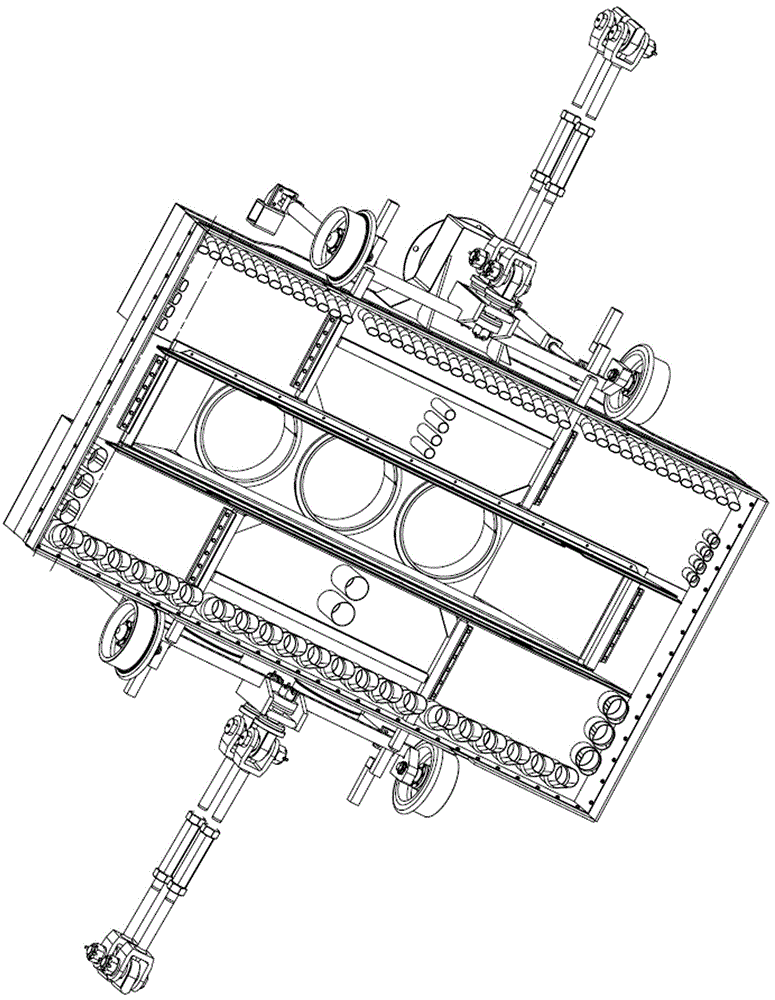

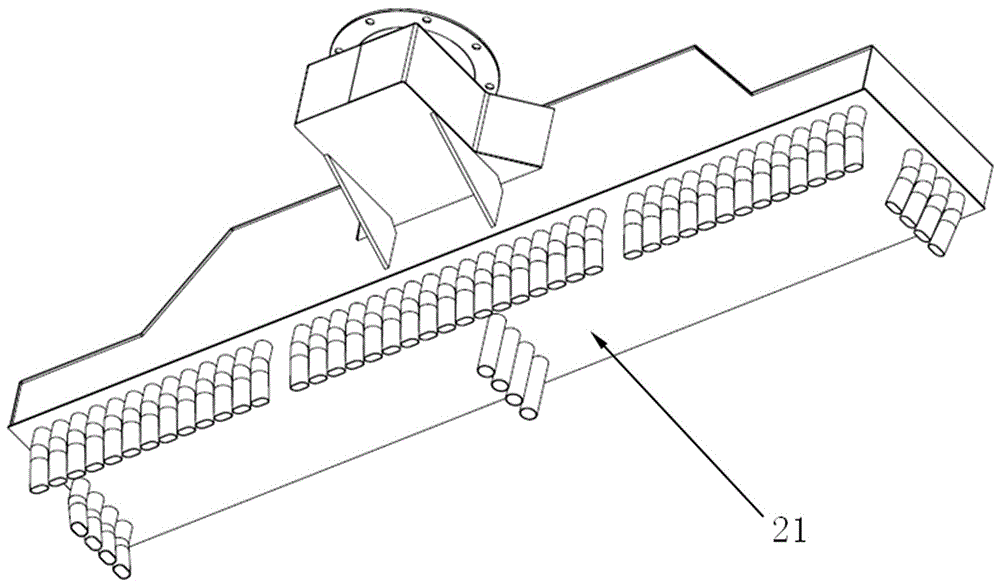

[0068] Example 1.1: The blowing and suction working device for the rail sewage suction vehicle, such as figure 1 , figure 2 The blowing and sucking working device for the rail sewage suction vehicle provided by this embodiment includes:

[0069] The trolley frame 4, the trolley frame 4 is a plane hood frame, the front and rear sides of the plane hood frame are respectively provided with two working wheels 5, which are used to fall on the rail during operation and roll;

[0070] Drawbars 1 installed on the front and rear sides of the trolley frame 4; one end of each drawbar 1 is connected to the center of the front / rear side of the trolley frame 4 for sewage suction work, and the other end of each drawbar 1 is connected to the track for sewage suction On the car body; the drawbar 1 is used for pulling the track sewage suction truck to run with the sewage suction work trolley when the track sewage suction truck is running.

[0071] The front blowing box 2 and the rear blowing...

Embodiment 12

[0085] Example 1.2: The blowing and sucking working device for a rail sewage suction vehicle is the same as Example 1.1, except that the bottom pipe diameter of the first blowing nozzle of the front blowing box is 120 mm.

Embodiment 13

[0086] Example 1.3: The blowing and suction working device for rail sewage suction vehicles is the same as Example 1.2, except that the angle between the curved part of the head of the first blowing nozzle and the bottom is 165 o .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com