A reactor for producing natural gas from pulverized coal pyrolysis

A pyrolysis reaction and natural gas technology, which is applied in the field of coal gasification and pyrolysis, can solve the problems of large fluidized bed pyrolysis equipment, high dust content in oil and gas, and small production capacity, and achieve compact structure, clean oil and gas products, and improved The effect of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are only a part of the present invention. Other embodiments obtained below all belong to the protection scope of the present invention.

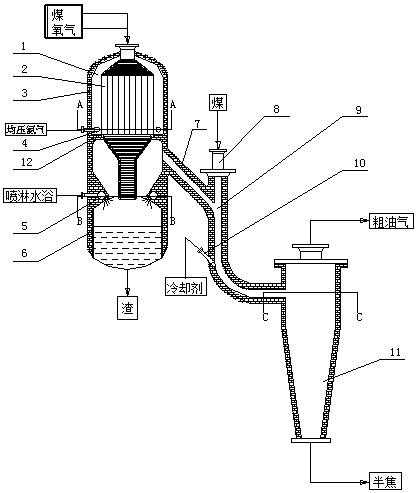

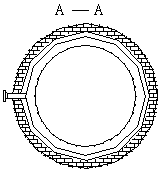

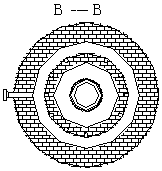

[0022] Such as figure 1 , 2 , 3 and 4, a reactor for producing natural gas by pyrolysis of pulverized coal, comprising: a water wall gasification chamber 1, a coal hydropyrolysis reaction chamber 9, a cyclone separator 11, and the water wall gasification The top of the chamber 1 is provided with inlets for raw material oxygen and pulverized coal for hydrogen production. The water-cooled wall gasification chamber 1 is provided with a water-cooled wall 2. 1. The inner wall is made of refractory bricks 3. The middle part of the water-cooled wall gasification chamber 1 is built with refractory bricks to form a partition wall 12. A pressure equalizing nitrogen rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com