Production device of mucilage glue based active carbon fibers and energy-saving and environment-protection method

An activated carbon fiber, energy-saving and environment-friendly technology, applied in the fields of fiber chemical characteristics, textile/flexible product manufacturing, climate sustainability, etc. Reduce the economic benefits of enterprises and other issues, to achieve the effect of reducing direct investment, significant economic benefits, and overall cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail through the accompanying drawings and embodiments. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not used to limit the scope of the present invention.

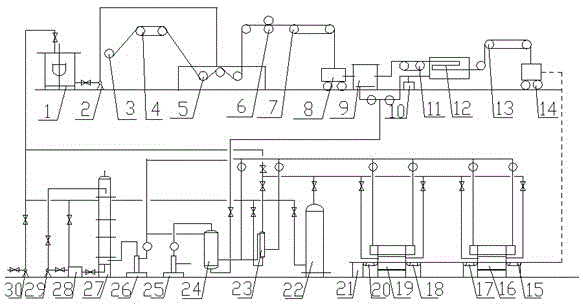

[0056] An activated carbon fiber production equipment, including a catalytic system, a dehydration system, a carbonization / activation system and an energy-saving system;

[0057] The catalytic system includes a reactor 1, a material pump 2, a felt release machine 3, a felt feeder 4, a catalytic tank 5, a dehydrator 6, a felt placement machine 7, a wet felt car 8 and a clean water pump 30. The water pump 30 is connected to the reactor 1 and injects water into the reactor 1. The reactor 1 is connected to the catalytic tank 5 through the material pump 2, and the felting machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com