Support-shaped jet type oil mixing device

A jetting, oil mixing technology, applied in mixers, mixers, fluid mixers, etc. with rotary stirring devices, can solve the problem of inconsistent oil technical quality indicators, limited power of the storage tank drive system, design and installation process Complex problems, to achieve the same technical quality indicators of oil products, ensure the effect of mechanical stirring, and increase the effect of mechanical stirring methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

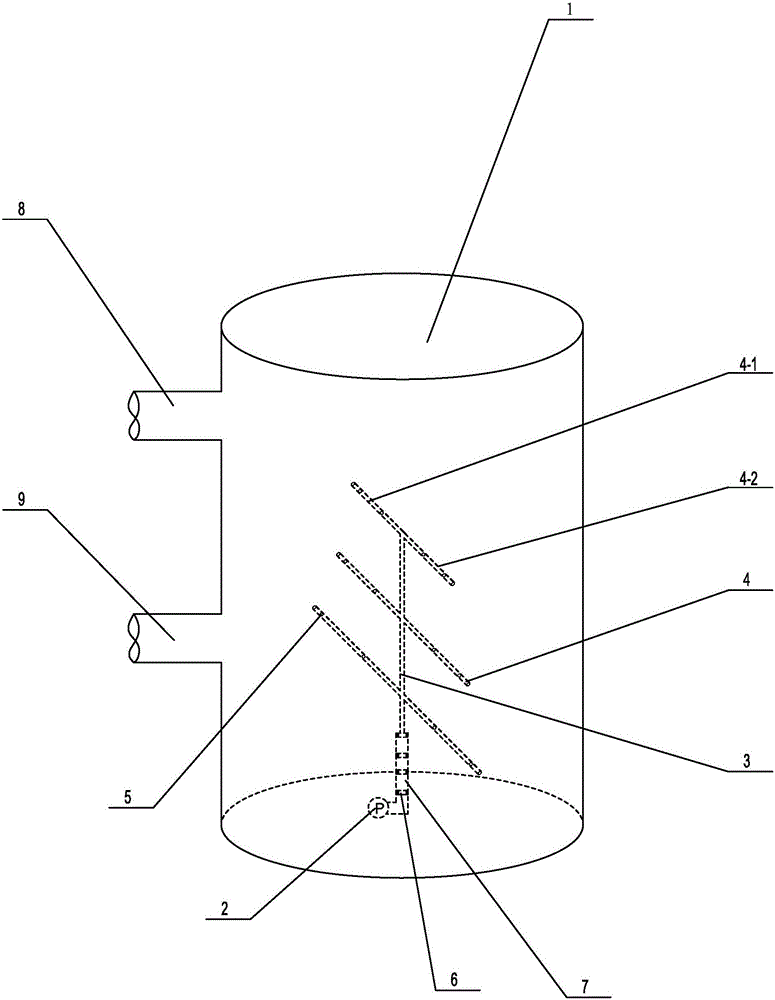

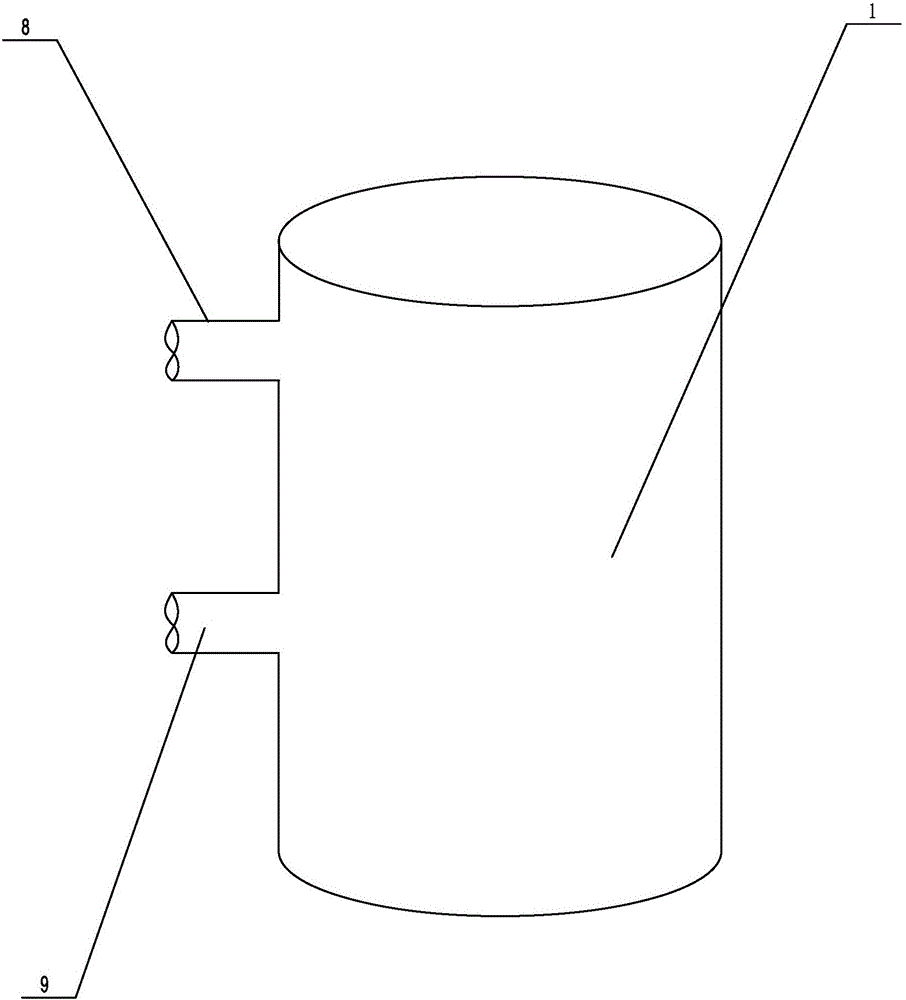

[0026] Such as figure 1 with figure 2 Propose a kind of specific embodiment of the present invention as shown, a kind of support-like jet oil mixing device, comprise tank body 1, the upper end of this tank body 1 outer wall is provided with oil inlet pipe 8, and the lower end is provided with oil outlet pipe 9, and described tank The bottom of the body 1 is provided with an explosion-proof servo submersible pump 2. The submersible pump 2 is connected to an external power supply through an explosion-proof power cord, and the output power is adjusted by frequency conversion. The submersible pump 2 is connected to a vertically installed The delivery pipe 3, the delivery pipe 3 is provided with several injection branch pipes 4 with the same diameter along the vertical direction, and the injection branch pipe 4 includes a left branch pipe 4-1 and a right branch pipe installed symmetrically with the delivery pipe 3 as the center line 4-2, the front (rear) side of the left branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com