Method and device for improving dust removal effect and explosion-proof performance of dust remover

A technology of cleaning device and dust collector, which is applied in chemical instruments and methods, separation methods, transportation and packaging, etc., can solve the problems of large consumption of inert powder, difficulty in packaging, and insignificant dust removal effect, and achieves easy operation and improved efficiency. Explosion-proof performance, the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

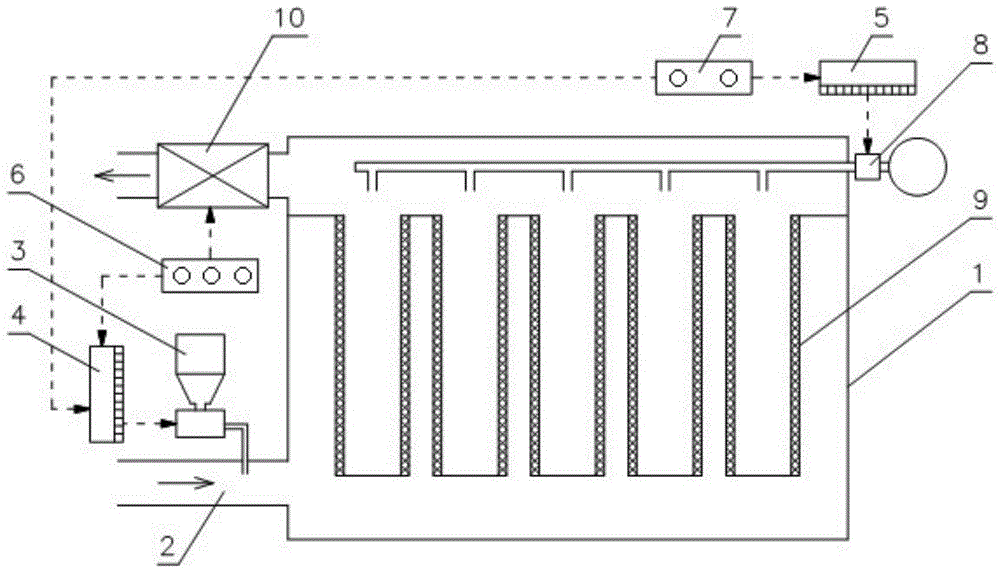

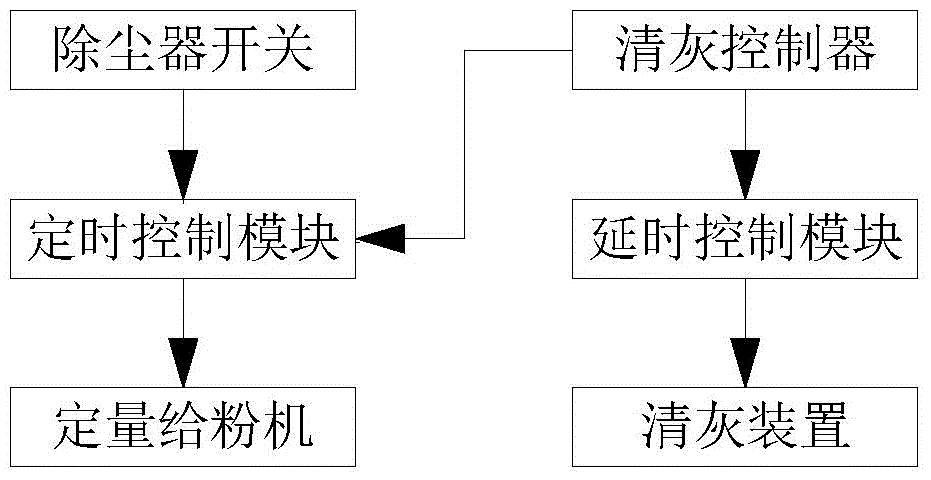

[0025] Such as figure 1 As shown, a device for improving the dust cleaning effect and explosion-proof performance of the dust collector includes a quantitative powder feeder 3, a timing control module 4, a delay control module 5, a dust cleaning controller 7 and a dust cleaning device 8, and the quantitative feeding The entrance of the powder machine 3 passes through the side wall of the air inlet pipe 2 of the dust collector 1, and the quantitative powder feeder 3 is connected with the timing control module 4; the timing control module 4 is connected with the dust collector switch 6 and the dust removal controller 7 respectively. connected; the dust collector switch 6 is connected to the fan 10; the delay control module 5 is connected to the dust removal controller 7 and the dust removal device 8 respectively.

[0026] The timing control module 4 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com