Preparing method suitable for radix aconiti kusnezoffi preparata

A technology for producing Fructus Fructus and Fructus Fructus, applied in the field of processing Chinese medicinal materials, can solve the problems of incomplete hydrolysis of toxic components, long production cycle of Fructus Fructus, insufficient content of active ingredients, etc., so as to save production time, reduce toxicity and reduce risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

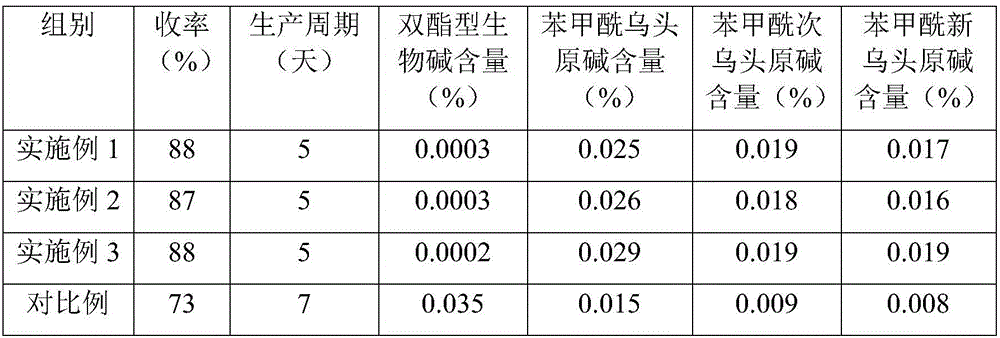

Examples

Embodiment 1

[0024] The specific steps of the processing method applicable to the processing of Aconitum aconitum of the present invention are as follows:

[0025] (1) Purification: remove the impurities in the raw material medicine of Aconitum aconitum, and obtain a clean raw material medicine of Aconitum aconitum;

[0026] (2) Grading: separate Aconitum aconitifolia into large and small ones, and weigh them respectively. The diameter of the large Aconitum aconitidis is 1.5cm and above, and the diameter of the small Aconitum aconitidis is less than 1.5cm;

[0027] (3) Soaking: Put the Aconitum aconitum graded above into clean water tanks with a constant temperature water bath device, control the temperature at 30°C, soak the big ones for 3 days, change the water twice a day, until there is no dry core inside; soak the small ones For 2 days, change the water twice a day, soak until there is no dry core inside, take it out, and drain;

[0028] (4) Steaming: Divide the soaked Aconitum aconi...

Embodiment 2

[0032] The specific steps of the processing method applicable to the processing of Aconitum aconitum of the present invention are as follows:

[0033] (1) Purification: remove the impurities in the raw material medicine of Aconitum aconitum, and obtain a clean raw material medicine of Aconitum aconitum;

[0034] (2) Grading: separate Aconitum aconitifolia into large and small ones, and weigh them respectively. The diameter of the large Aconitum aconitidis is 1.5cm and above, and the diameter of the small Aconitum aconitidis is less than 1.5cm;

[0035] (3) Soaking: put the Aconitum aconitum graded above into a clean water tank with a constant temperature water bath device, control the temperature at 35 ° C, soak for 3 days, change the water twice a day, and soak until there is no dry core inside; soak the small ones For 2 days, change the water twice a day, soak until there is no dry core inside, take it out, and drain;

[0036] (4) Steaming: Divide the soaked Aconitum aconit...

Embodiment 3

[0040] The specific steps of the processing method applicable to the processing of Aconitum aconitum of the present invention are as follows:

[0041] (1) Purification: remove the impurities in the raw material medicine of Aconitum aconitum, and obtain a clean raw material medicine of Aconitum aconitum;

[0042] (2) Grading: separate Aconitum aconitifolia into large and small ones, and weigh them respectively. The diameter of the large Aconitum aconitidis is 1.5cm and above, and the diameter of the small Aconitum aconitidis is less than 1.5cm;

[0043] (3) Soaking: put the Aconitum aconitum graded above into a clean water tank with a constant temperature water bath device, control the temperature at 33 ° C, soak for 3 days, change the water twice a day, and soak until there is no dry core in it; soak the small ones For 2 days, change the water twice a day, soak until there is no dry core inside, take it out, and drain;

[0044] (4) Steaming: Divide the soaked Aconitum aconitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com