Tobacco sheet coating liquid and preparation method thereof

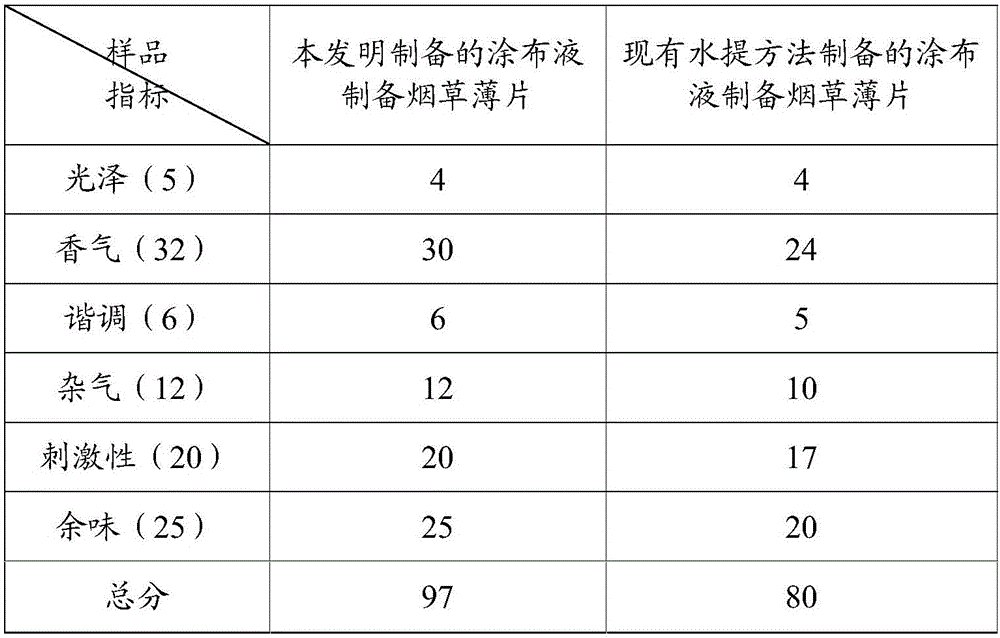

A technology of tobacco sheet and coating liquid, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of heavy air, affecting the use effect, and high irritation of the tobacco sheet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: the preparation of tobacco sheet coating liquid

[0068] The implementation steps of this embodiment are as follows:

[0069] A. Preparation of alkalized tobacco powder

[0070] According to the weight ratio of waste smoke powder to quicklime 100:8, add 40 mesh quicklime powder to 75 mesh waste smoke powder, mix evenly, and then add waste smoke powder to the mixture of waste smoke powder and quicklime according to the weight ratio of waste smoke powder and purified water 1:1 Add purified water, stir evenly, infiltrate and alkalize for 6 hours to obtain an alkalized tobacco powder;

[0071] B. Extraction

[0072] According to the weight ratio of waste smoke powder and organic solvent 1:4, add ethyl acetate organic solvent to the alkalized smoke powder obtained in step A at room temperature to extract for 5.5 hours, filter to obtain filtrate and filter residue; Under the condition of repeated extraction 2 times, the residual filter residue was discarded, ...

Embodiment 2

[0078] Embodiment 2: the preparation of tobacco sheet coating liquid

[0079] The implementation steps of this embodiment are as follows:

[0080] A. Preparation of alkalized tobacco powder

[0081] According to the weight ratio of waste smoke powder and quicklime 100:12, add 50 mesh quicklime powder to 75 mesh waste smoke powder, mix evenly, and then add waste smoke powder and quicklime mixture according to the weight ratio of waste smoke powder and purified water 1:1.1 Add purified water, stir evenly, infiltrate and alkalize for 12 hours to obtain an alkalized tobacco powder;

[0082] B. Extraction

[0083] According to the weight ratio of waste smoke powder and organic solvent 1:7, add dichloromethane organic solvent to the alkalized smoke powder obtained in step A at room temperature to extract for 6.5 hours, filter to obtain filtrate and filter residue; Under the condition of repeated extraction 3 times, the residual filter residue was discarded, and all filtrates were...

Embodiment 3

[0089] Embodiment 3: the preparation of tobacco sheet coating liquid

[0090] The implementation steps of this embodiment are as follows:

[0091] A. Preparation of alkalized tobacco powder

[0092] According to the weight ratio of waste smoke powder and quicklime 100:6, add 30 mesh quicklime powder to 60 mesh waste smoke powder, mix well, and then add waste smoke powder and quicklime mixture according to the weight ratio of waste smoke powder and purified water 1:0.8 Add purified water, stir evenly, infiltrate and alkalize for 4 hours to obtain an alkalized tobacco powder;

[0093] B. Extraction

[0094] According to the weight ratio of waste smoke powder and organic solvent 1:3, add ethyl acetate organic solvent to the alkalized smoke powder obtained in step A at room temperature to extract for 4 hours, filter to obtain filtrate and filter residue; Under the condition of repeated extraction 4 times, the residual filter residue was discarded, and all filtrates were combine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com