Process for obtaining heat sterilizable injectable hydrogels based on hyaluronic acid containing lidocaine and alkaline agents added in powder form

A technology of hyaluronic acid and lidocaine, applied in the field of therapy and cosmetology, which can solve the problems of injectable hydrogels changing flow properties and methods not fully satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

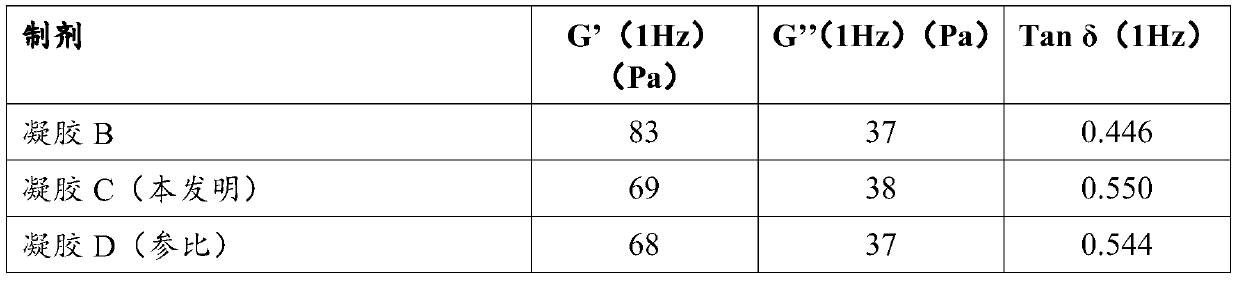

[0071] Example 1: Structural differences after moist heat sterilization demonstrated by rheology between hyaluronic acid-based gels with and without lidocaine hydrochloride and with lidocaine hydrochloride and sodium hydroxide

[0072] Let the cross-linked NaHA based gel be A.

[0073] This gel is obtained as follows: Molecular mass 2.5 x 10 hydrated in 1 mass % aqueous sodium hydroxide soda solution 6 Da of sodium hyaluronate, crosslinking agent BDDE added to obtain a degree of crosslinking of 9%, crosslinking for 2 h at 50° C. and dialyzing the gel for 24 h (regenerated cellulose, separation limit: molar mass = 60 kDa). The gel thus obtained had a sodium hyaluronate concentration of 22.5 mg / ml and a pH of 7.07.

[0074] After mixing with a spatula for 10 minutes, the gel A thus obtained was divided into three portions (50 g) of equal mass.

[0075] Let part 1 be B. In this part, 0.3% lidocaine hydrochloride is added as a powder. The gel was mixed with a spatula for 5 m...

Embodiment 2

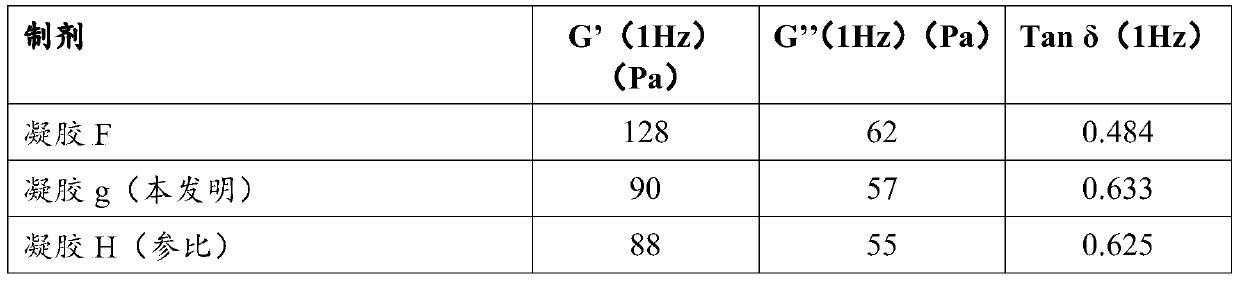

[0087] Example 2: Structural differences after moist heat sterilization demonstrated by rheology between hyaluronic acid-based gels with and without lidocaine hydrochloride and with lidocaine hydrochloride and sodium hydroxide

[0088] Let the cross-linked NaHA based gel be E.

[0089] This gel is obtained as follows: Molecular mass 2.5 x 10 hydrated in 1 mass % sodium hydroxide solution 6Da of sodium hyaluronate, crosslinking agent BDDE added to obtain a degree of crosslinking of 11%, crosslinking for 2 h at 50° C. and dialyzing the gel for 24 h (regenerated cellulose, separation limit: molar mass = 60 kDa). The gel thus obtained had a sodium hyaluronate concentration of 22.7 mg / ml and a pH of 7.12.

[0090] After mixing with a spatula for 10 minutes, the gel E thus obtained was divided into three portions (50 g) of equal mass.

[0091] Let part 1 be F. In this part, 0.3% lidocaine hydrochloride is added as a powder. The gel was mixed with a spatula for 5 minutes. Then...

Embodiment 5

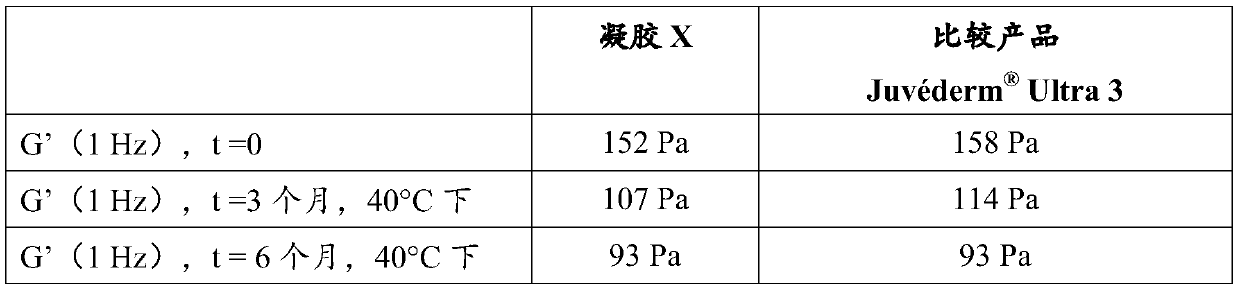

[0112] Example 5: Stability of the gels of the present invention - comparison with prior art stable gels

[0113] The cross-linked NaHA-based gel was prepared as follows: Hydration molecular mass 3.1 × 10 in 1 mass % aqueous sodium hydroxide solution 6 Da of sodium hyaluronate, crosslinking agent BDDE added to obtain a degree of crosslinking of 9.2%, crosslinking for 2 hours at 50 and dialysis for 24 hours (regenerated cellulose, separation limit: molar mass = 60 kDa). The gel thus obtained had a sodium hyaluronate concentration of 24.9 mg / ml and a pH of 7.08.

[0114] Next 0.3% lidocaine hydrochloride was added and the gel was mixed with a spatula for 5 minutes. The pH was found to be 6.77.

[0115] Finally, 144 μl of a 2 mass % aqueous sodium hydroxide solution was added and mixed with a spatula for 5 minutes. The final pH was 7.26.

[0116] The thus prepared gel was introduced into a glass syringe and then heat sterilized (131°C, 2 min).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com