Flywheel-type motor for diesel engine

A diesel engine, flywheel motor technology, applied in electromechanical devices, electrical components, magnetic circuit rotating parts, etc., can solve the problem of not retrieving the disc type salient pole structure, etc., to avoid difficulty in voltage regulation control and eliminate costs high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention will be described in further detail below in conjunction with the accompanying drawings.

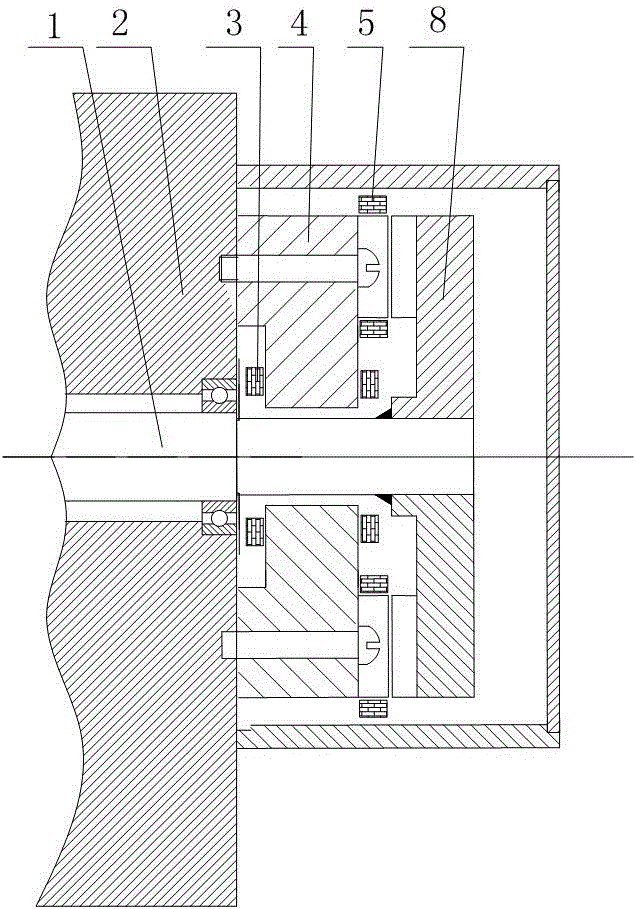

[0033] figure 1 It is a longitudinal sectional view of a flywheel motor for a diesel engine of the present invention. The shown flywheel motor for diesel engine is composed of crankshaft (1), excitation coil (3), stator core (4), armature coil and rotor core (8); the rotor core (8) is disc-shaped and fixed At the end of the crankshaft (1); the circular stator core (6) is fixed on the diesel engine casing (2), and the end face of the stator core (4) is perpendicular to the axis of the crankshaft (1) and aligned with the crankshaft (1) concentric.

[0034] Both the stator core (4) and the rotor core (8) are made of non-oriented magnetically permeable materials.

[0035] The size of the air gap magnetic field can be adjusted by adjusting the magnitude of the excitation current, so that the flywheel motor for the diesel engine can maintain the stability of the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com