Non-aqueous electrolyte for high-voltage rapid-charging type lithium ion battery

A non-aqueous electrolyte, lithium-ion battery technology, applied in non-aqueous electrolytes, secondary batteries, organic electrolytes, etc., can solve the problems of reduced cycle performance, restricted performance of positive electrode materials, limited and other problems, to improve oxidation resistance, improve The effect of fast charge cycle at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

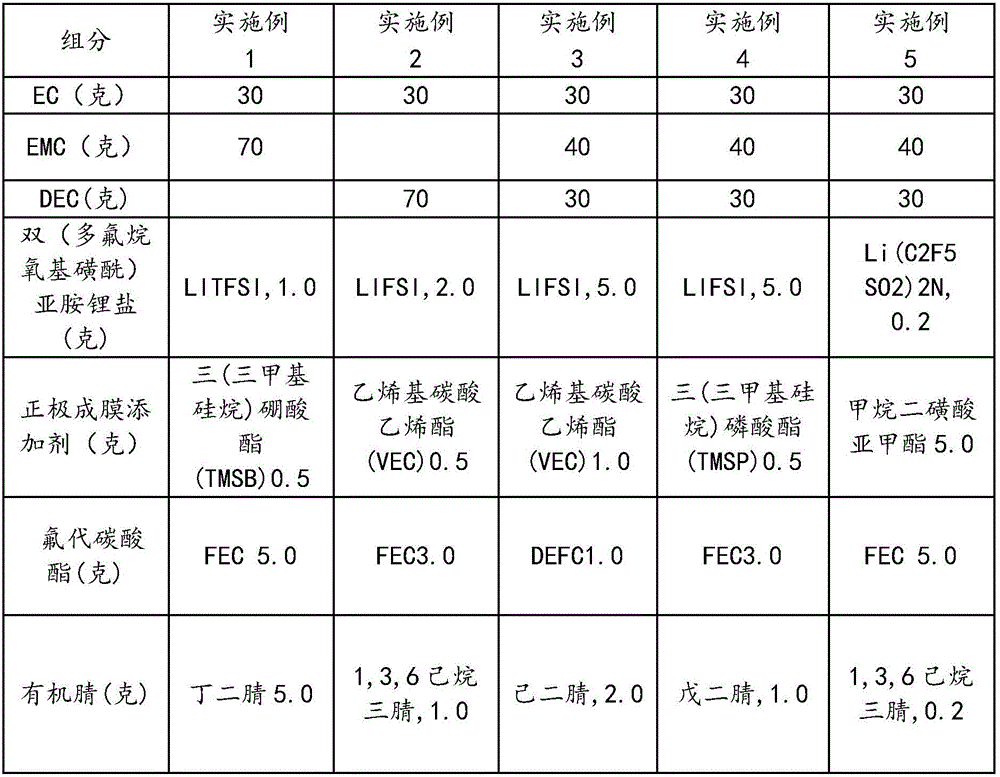

Examples

Embodiment 1

[0032] The electrolyte was prepared in a BRAUN glove box filled with nitrogen with a purity of 99.999%, the moisture in the glove box was controlled at ≤5ppm, and the temperature was at room temperature. Mix 30 grams of EC and 70 grams of EMC evenly, seal it, put it in the refrigerator until it cools to 8°C, transfer it to the glove box, and then add LiPF in two batches 6 Mix well to form a non-aqueous electrolyte solution for lithium-ion batteries with a molar concentration of 1 mol / L commonly used lithium salt. Add 3% FEC, 2% LIFSI, and 3% propane sultone to the above non-aqueous electrolyte solution , 2% adiponitrile 1.5, after uniform mixing, a high-voltage lithium-ion non-aqueous electrolyte is obtained.

[0033] The preparation methods of the following other examples and comparative examples are carried out with reference to the preparation method of Example 1.

[0034] Among them, FEC (CAS: 114435-02-8), 1,3,5 pentanetricarbonitrile (4379-04-8), 1,2,3 propanetricarboni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com