Mixed cation perovskite and preparation method therefor

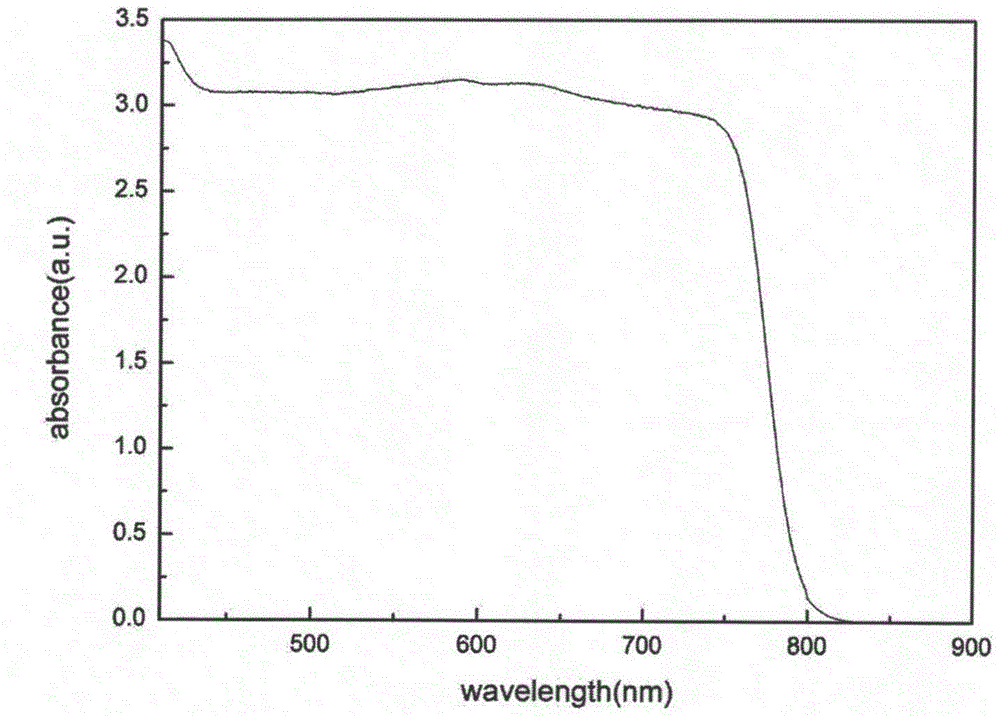

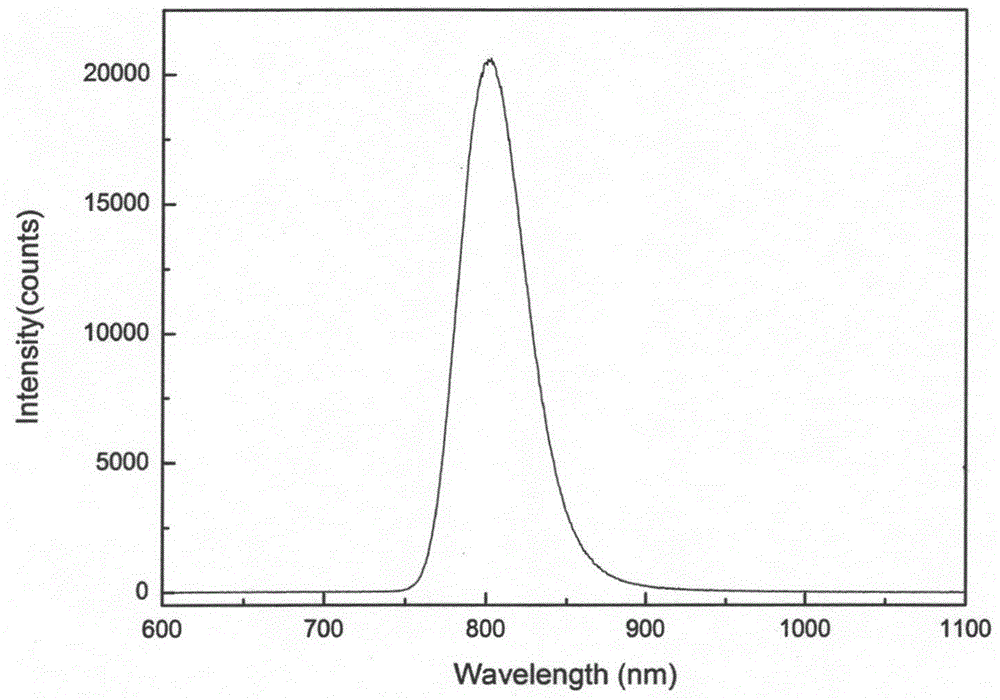

A technology of mixed cations and perovskites, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problem of single types, and achieve the effects of rich types, good photoluminescent properties, and good optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

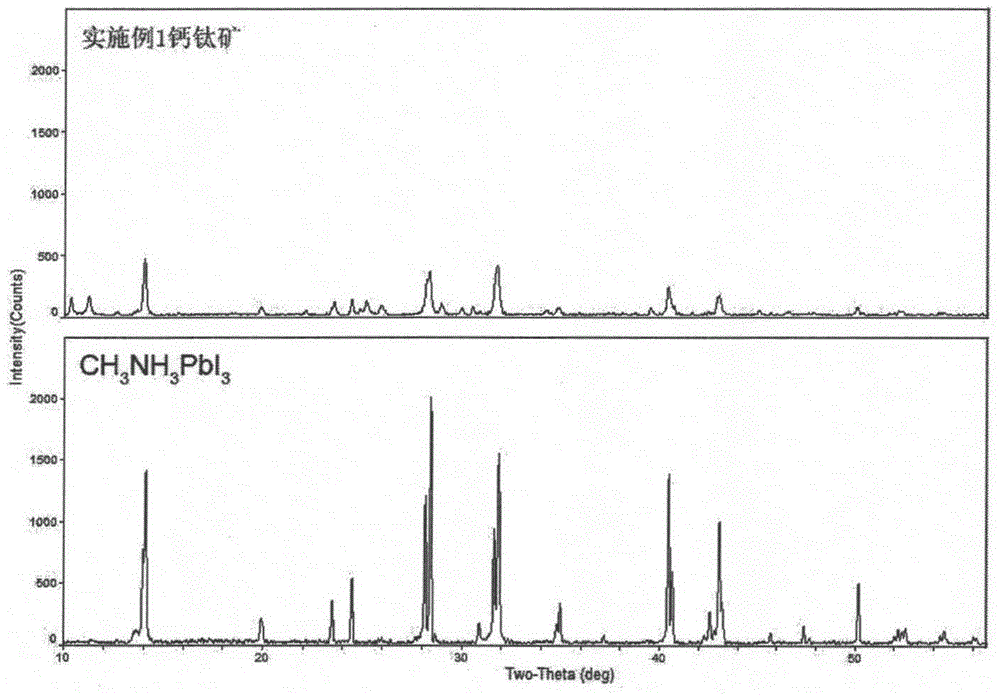

Embodiment 1

[0036] A mixed cation perovskite consisting of methylamine cations (CH 3 NH 3 + ), another organic amine cation, a metal cation and a halogen anion in a certain ratio.

[0037] The preparation method of described mixed cation perovskite is:

[0038] (1) Add 24ml mass concentration of 33% methylamine ethanol solution and 10ml mass concentration of 57% hydroiodic acid aqueous solution into a 250ml round bottom flask, stir and react at 0°C for two hours, use after the reaction The solvent was removed on a rotary evaporator at 50 °C. The obtained solid was purified by recrystallization. The specific steps were: redissolve the obtained solid in 80ml of absolute ethanol, then add 300ml of ether to precipitate the white precipitate, and filter it with a Buchner funnel. Recrystallization was repeated twice to obtain a white solid. Dry in a vacuum oven at 60° C. for 24 hours to obtain methyl iodide.

[0039] (2) 13ml mass concentration of 99% isopropylamine solution and 10ml mass...

Embodiment 2

[0045] A mixed cation perovskite consisting of methylamine cations (CH 3 NH 3 + ), another organic amine cation, a metal cation and a halogen anion in a certain ratio.

[0046] The preparation method of described mixed cation perovskite is:

[0047] (1) Add 24ml mass concentration of 33% methylamine ethanol solution and 10ml mass concentration of 57% hydroiodic acid aqueous solution into a 250ml round bottom flask, stir and react at 0°C for two hours, use after the reaction The solvent was removed on a rotary evaporator at 50 °C. The obtained solid was purified by recrystallization. The specific steps were: redissolve the obtained solid in 80ml of absolute ethanol, then add 300ml of ether to precipitate the white precipitate, and filter it with a Buchner funnel. Recrystallization was repeated twice to obtain a white solid. Dry in a vacuum oven at 60° C. for 24 hours to obtain methyl iodide.

[0048] (2) 2.68ml mass concentration is that 99% 1,2-propylenediamine solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com