A Design and Type Selection Method of Steel Ball Coal Mill Based on Genetic Optimization Algorithm

A steel ball coal mill, genetic optimization technology, applied in the direction of genetic rules, constraint-based CAD, gene model, etc., can solve the problems of steel ball coal mill size design without quantitative basis, large selection margin, and parameter mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

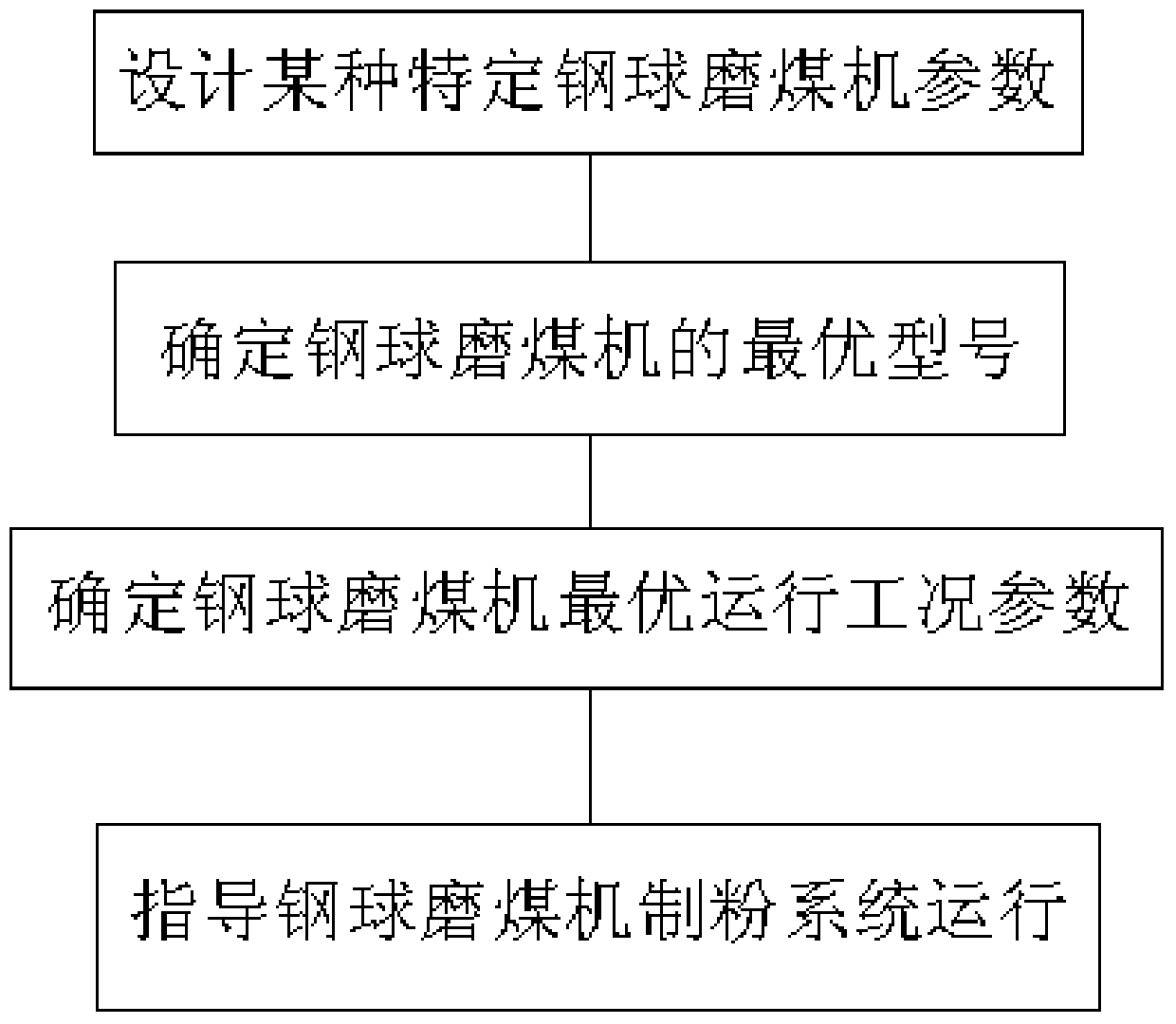

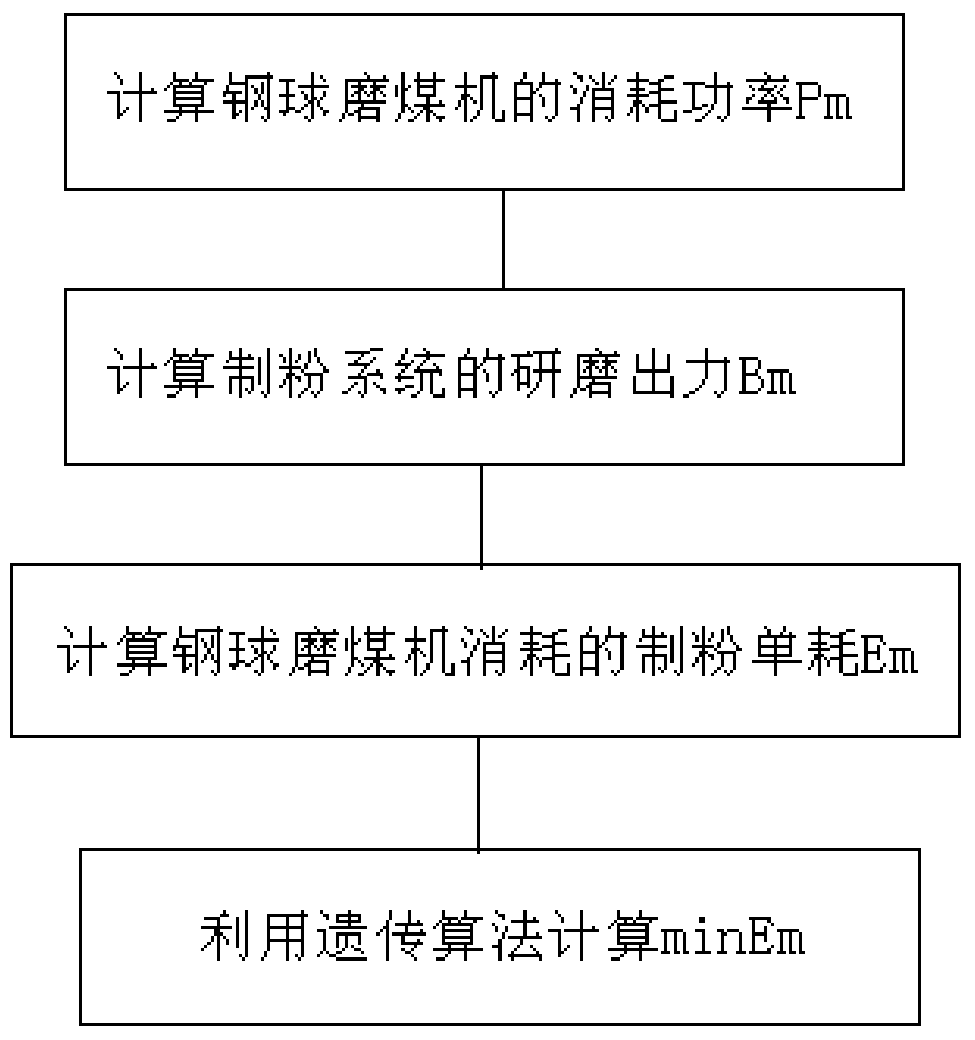

[0065] Such as Figure 1 to Figure 7 As shown, the present invention includes:

[0066] Step 1), designing the parameters of a certain specific steel ball coal mill;

[0067] Step 2), select the optimal model of steel ball coal mill from the model of designed steel ball coal mill and existing models;

[0068] Step 3), determining the optimal operating condition parameters of the steel ball coal mill;

[0069] Step 4), guiding the operation of the pulverized steel ball mill pulverization system.

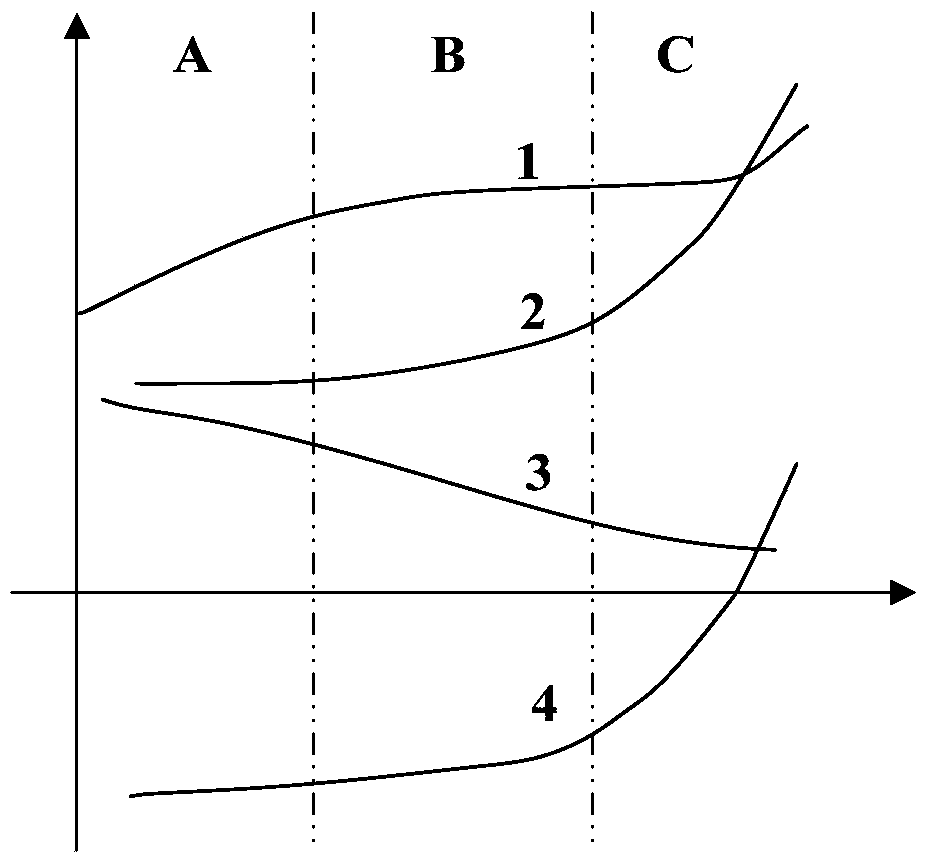

[0070] Such as figure 2 As shown, with the increase of coal storage in the steel ball coal mill, the power consumption of the ball mill represented by curve 1 also increases, the pressure difference between the inlet and outlet of the mill represented by curve 2 increases, and the outlet temperature of the mill represented by curve 3 decreases. The negative pressure at the mill inlet represented by curve 4 increases.

[0071] According to the characteristics of the curve, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com