A switch cabinet fault diagnosis method based on an on-line indirect temperature measurement mode

A fault diagnosis and switchgear technology, applied in the field of switchgear fault diagnosis based on online indirect temperature measurement, can solve the problems of difficult installation and popularization of temperature measurement sensors, high cost, etc., and achieve clear calculation and diagnosis process, fast diagnosis, The effect of strong data computability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

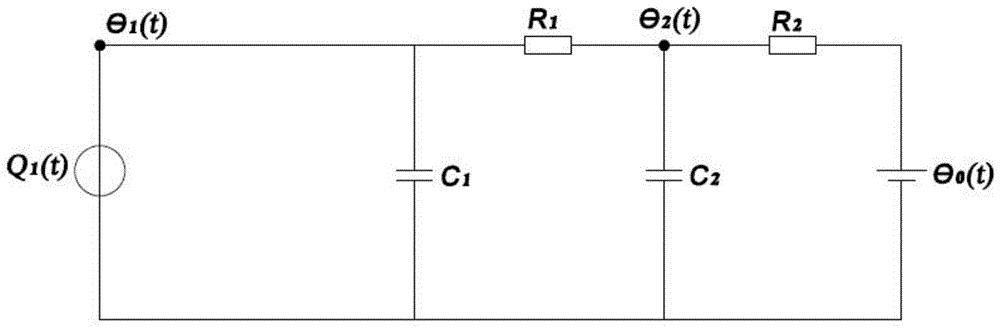

Image

Examples

example 1

[0101] For the high-voltage switchgear of Example 1, the diagnostic conclusion is: there is a possibility of hidden dangers.

[0102] The third method is based on the diagnostic method and diagnostic standard of comparing the ideal temperature of the load in the center of the lumped heat source in the switchgear with the heat transfer temperature of the center of the lumped heat source in the switchgear.

[0103] Diagnosis rule: In this embodiment, the transformation ratio coefficient between the load ideal temperature of the lumped heat source center in the switchgear and the heat transfer temperature of the lumped heat source center in the switchgear is:

[0104] According to the relevant temperature and temperature rise limit standards in the "GBT11022-2011 Common Technical Requirements for High Voltage Switchgear and Control Equipment Standards", and based on the mild heat generation unbalanced heat generation mode, the general threshold diagnostic standard is calculated as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com