High-temperature performance testing device for polyimide bushing with special-shaped end face

A polyimide, high-temperature performance technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problems of different axis of mounting pressure rods, large differences in end surface dimensions, and special-shaped end surfaces, etc., to avoid The special-shaped end face is stressed, the coaxiality of the force is high, and the effect of line contact is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

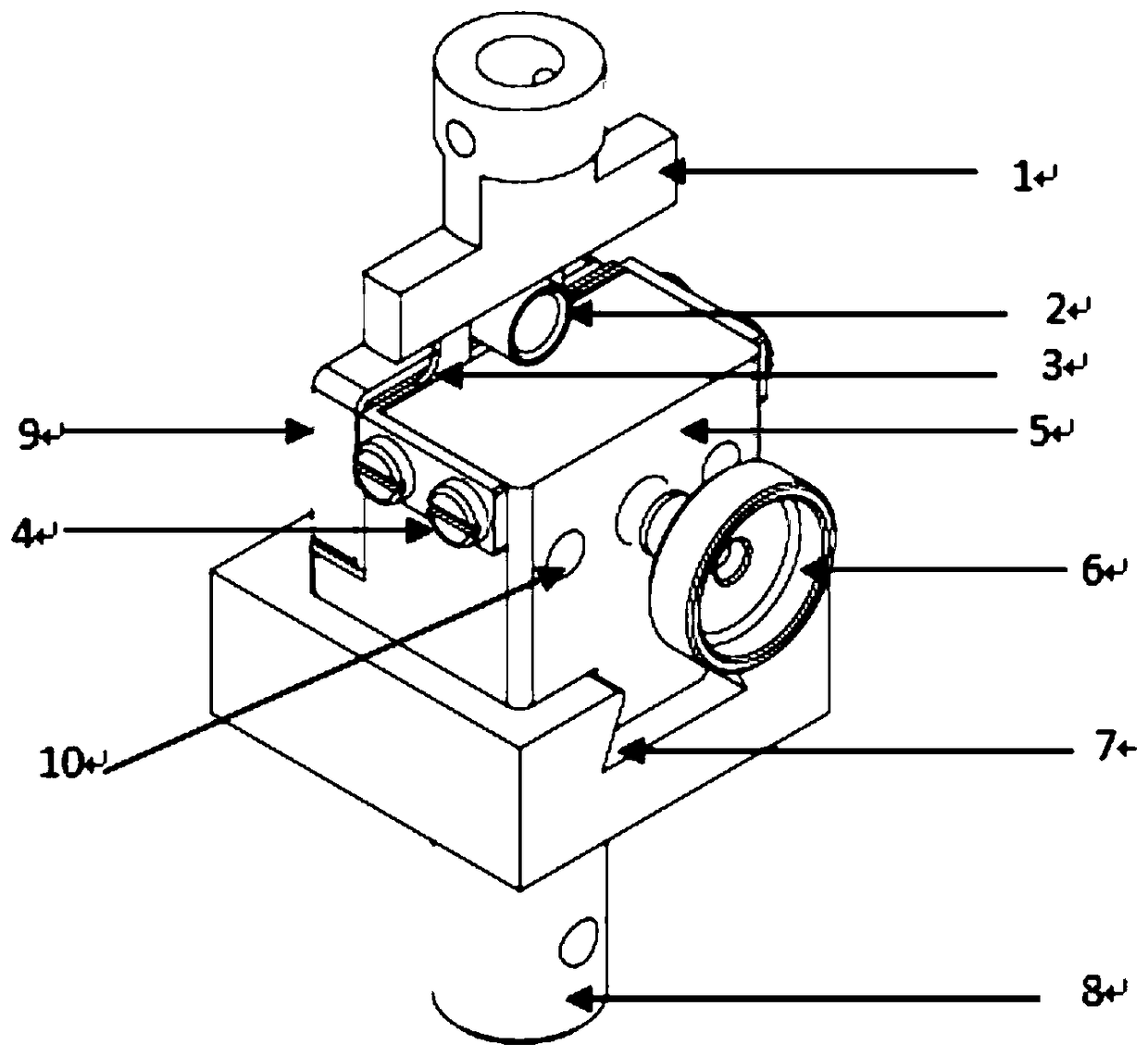

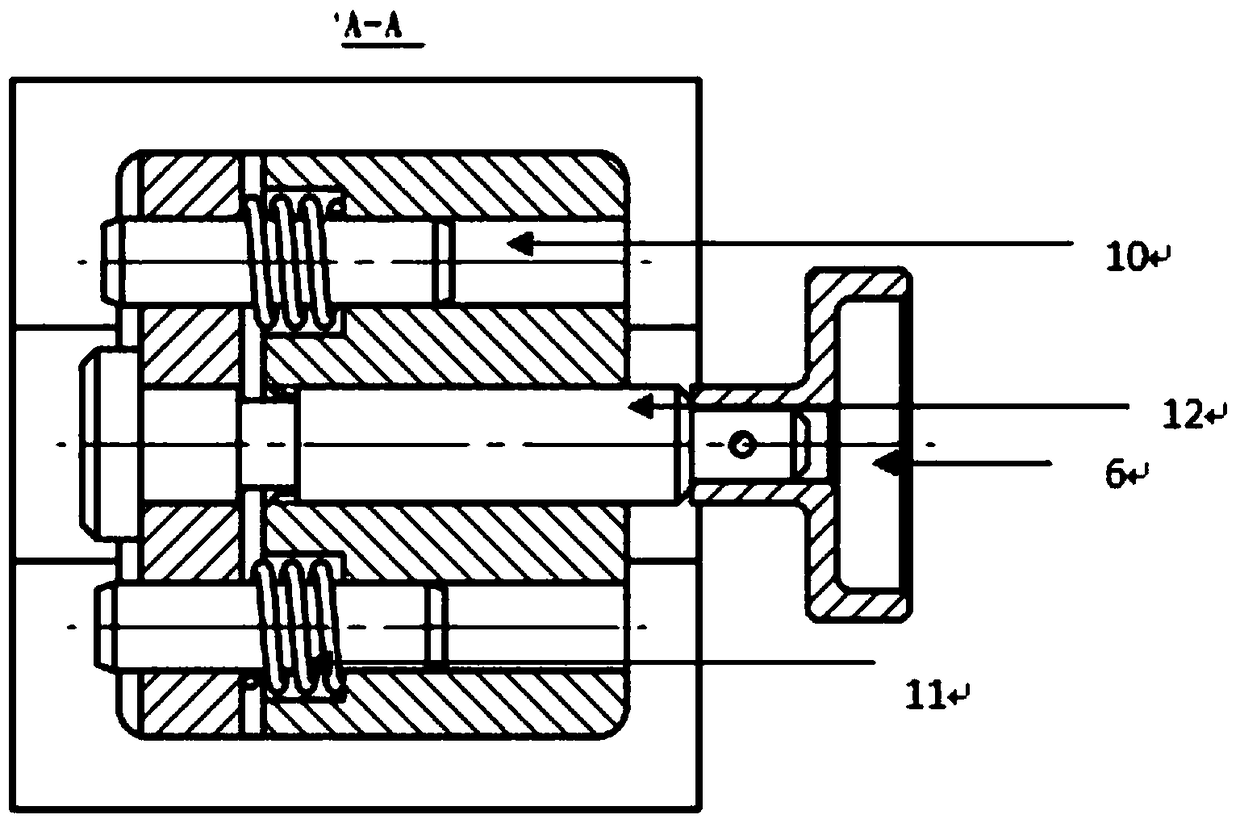

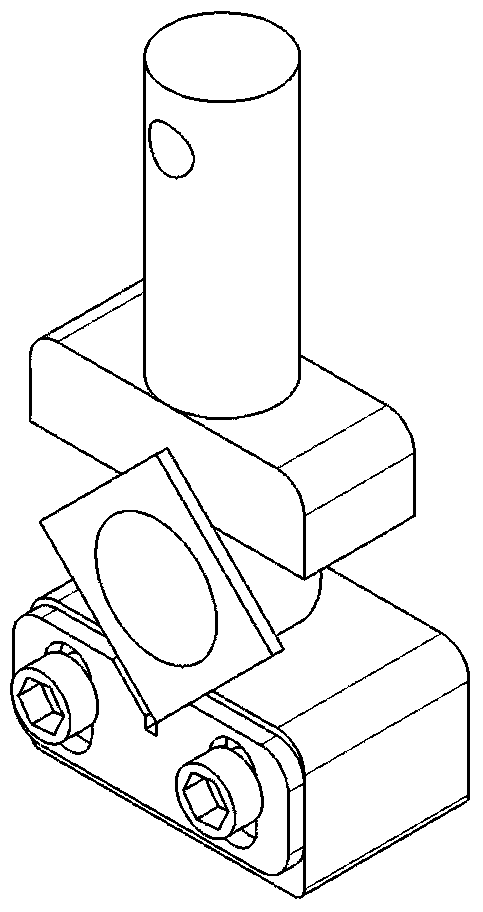

[0015] refer to figure 1 , figure 2 .In the embodiment described below, the high-temperature performance detection device of polyimide bushing with special-shaped end face is composed of indenter 1, baffle plate 3, fixing nut 4, compression test bench 5, adjusting nut 6, and dovetail guide groove 7. It is composed of support pressing rod 8, pressing baffle plate 9, guide rod 10, pre-tightening spring 11 and lateral adjustment rod 12. Wherein, the pressure head 1 and the supporting pressure rod 8 are connected to the high temperature tensile testing machine through pins. The upper end of the supporting pressure rod 8 is connected with the compression test bench (5) to play the role of fixing and supporting; the compression test bench 5 is made of a metal material with a certain hardness, and the test surface of the compression test bench 5 is marked with a test plate. The central scale line of the coaxiality when the sample is compressed. After the sample 2 is installed, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com