Wet paper molding method and paper plastic finished product

A molding method and wet paper technology, applied in textiles and papermaking, etc., can solve the problems of lengthening the overall process time, low production yield, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The technical content and detailed description of the present invention are now described as follows in conjunction with the drawings:

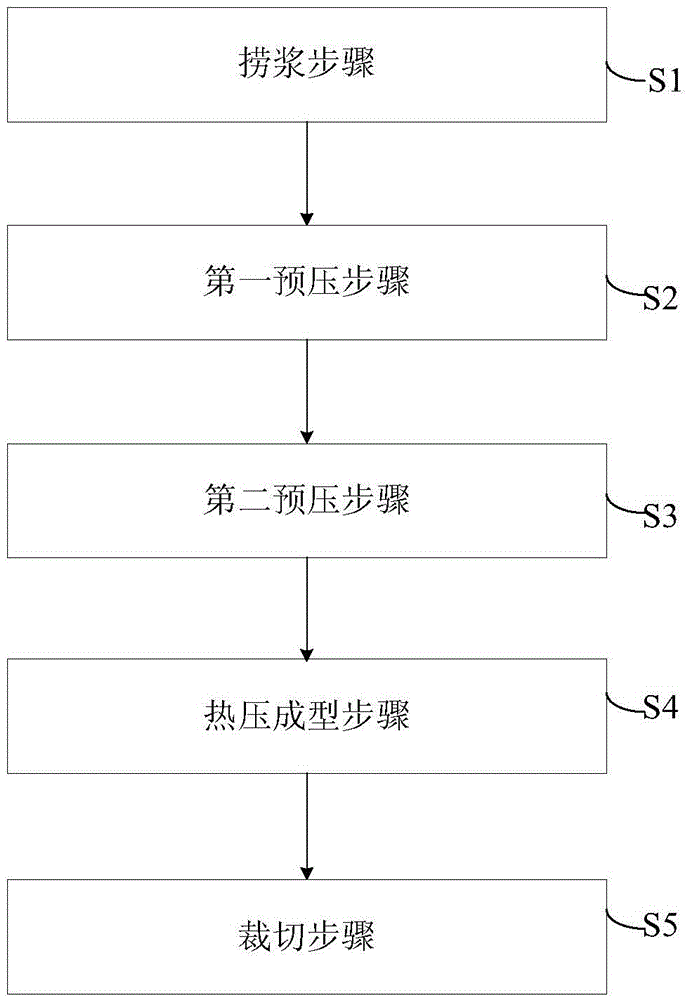

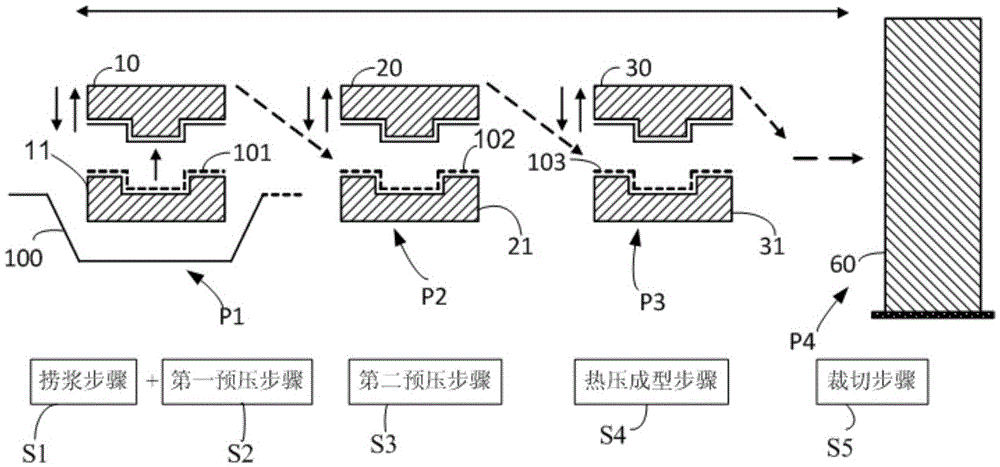

[0078] see figure 1 and Figure 5 shown, where figure 1 is a schematic flow chart of a wet paper molding method according to a preferred embodiment of the present invention, and Figure 5 as a way to implement figure 1 The structural schematic diagram of the multi-task station automation machine 70 of the described wet paper plastic molding method, the wet paper plastic molding method of the present invention is used to make the pulp material body 1002 into a dried paper plastic product 104 (see Figure 7 shown), including: at least one pulp extraction step S1, including using a first lower mold 11 to scoop up the pulp material body 1002 in a pulp tank 100, and then forming a pulp body 1002 above the first lower mold 11. A wet embryo (not shown) formed by the pulp material body 1002; a first pre-pressing step S2, a first upper mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com