Splice channel unit, splicer and textile machine

A technology of splicing channels and splicers, which is applied to spinning machines, textiles and papermaking, and continuous winding spinning machines, and can solve financial, supply and labor waste problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

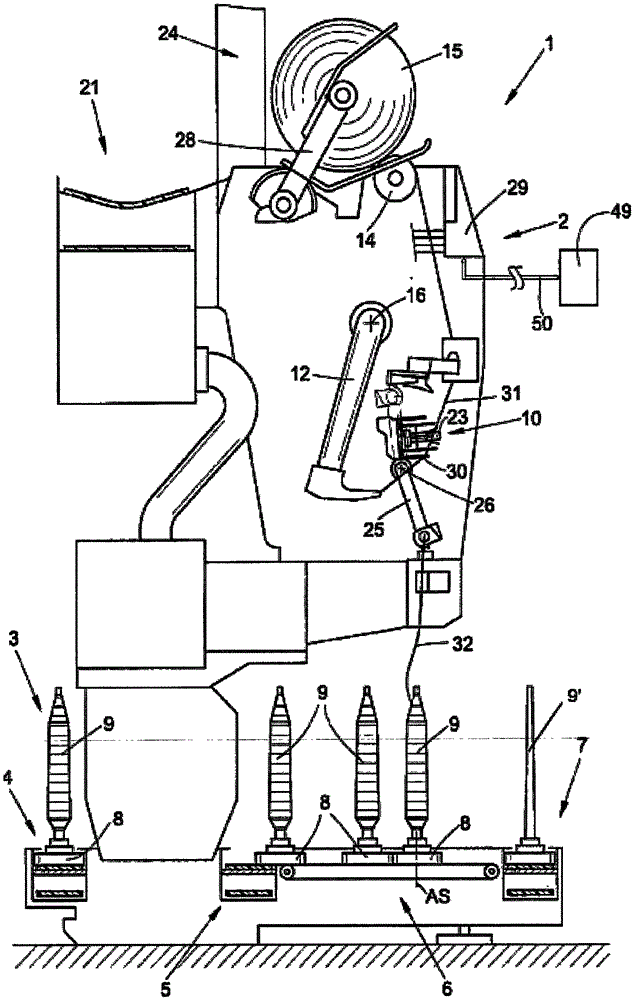

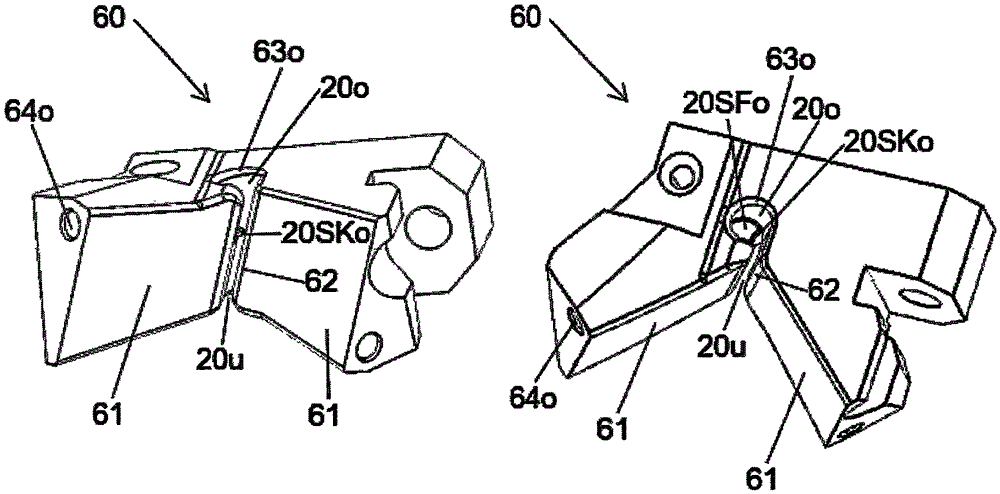

[0038] figure 1 - taken from DE 10 224 080 A1 (where the designation is also the same) - schematically shows a side view of a workstation 2 of a textile machine 1, in this case an automatic cross-winder 1 with a splicer 10, according to The splicing channel unit of the present invention can be used in the splicer. figure 2 - also taken from DE 10 224 080 A1 (also with the same designation) - a perspective view of the splicer 10 is then given.

[0039] Automatic crosswinders 1 of this type are known to have a plurality of identical workstations 2 , in the present case winding units 2 , between their end stations (not shown). At these package units, the winding bobbins 9 are rewound into bulky cross-wound packages 15 .

[0040] The package unit 2 has a splicer 10 (which is arranged slightly rearward with respect to the normal path of the yarn) to combine the so-called upper yarn 31 from the cross-wound package 15 and the yarn from the winding bobbin 9 The so-called lower yar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com