Machine for peeling tread of tyre

A stripping machine and tire technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, high labor intensity, difficult to master the operation method, etc., to reduce radial and axial runout, The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

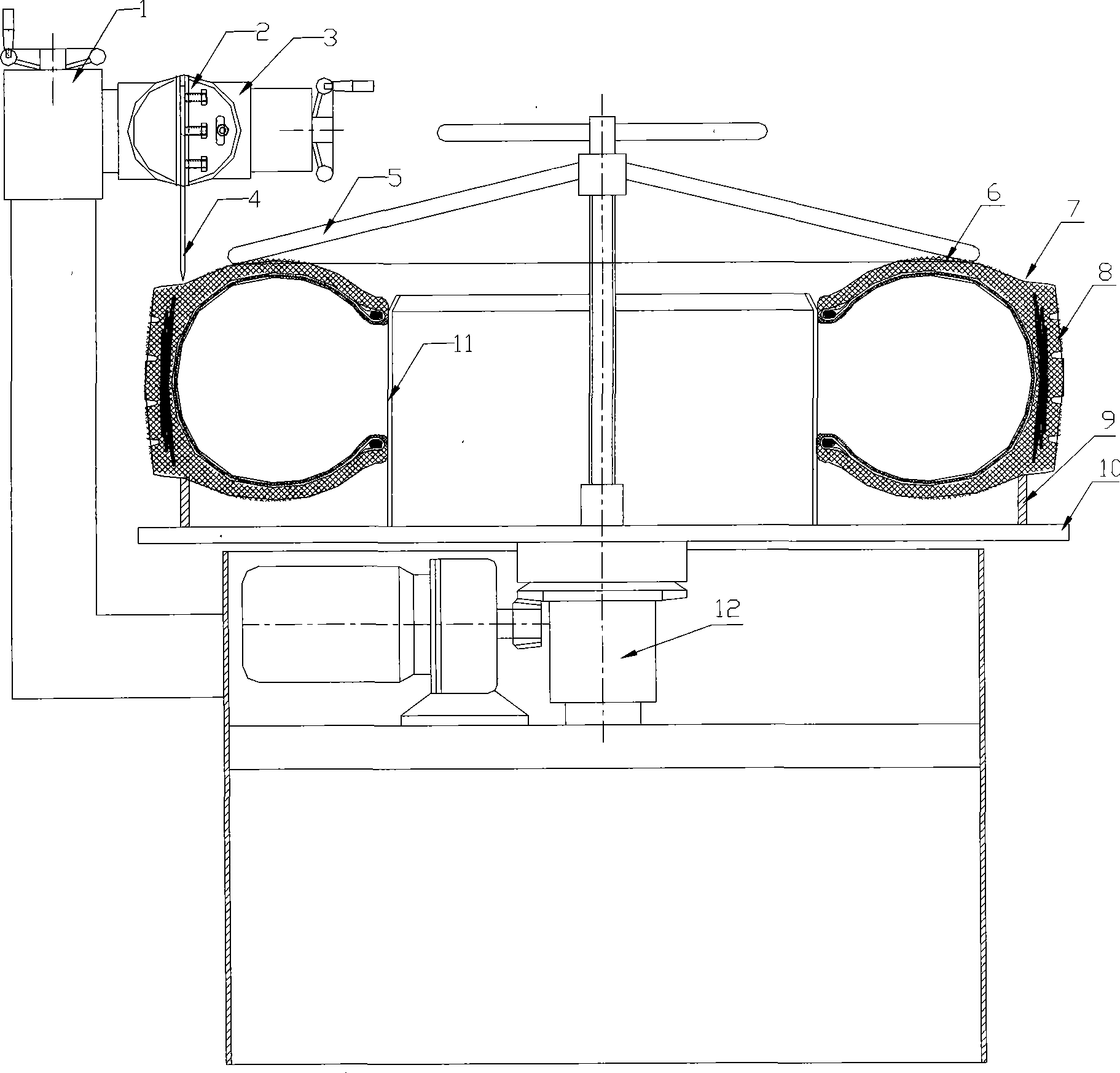

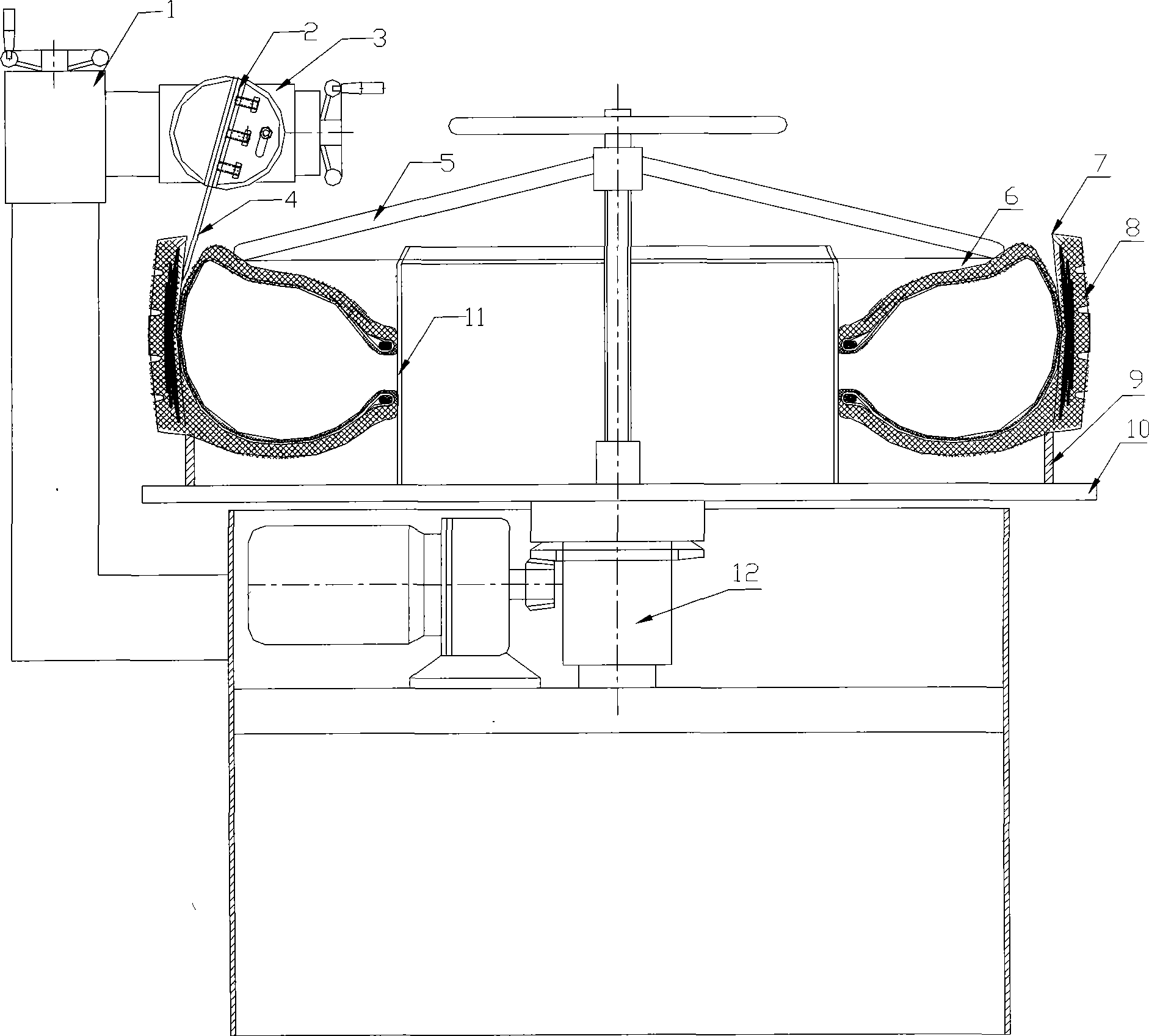

[0024] Examples such as figure 1 As shown, the feed mechanism of the tire crown stripping machine: the longitudinal slide 1 is provided with a cross arm, the transverse slide 3 is installed on the cross arm, the rotary knife rest 2 is installed on the transverse slide, and the knife 4 can be used for up and down, The radial movement and the swinging of the curved surface peeled off with the crown 8 of the tire can process tires of various specifications, and the rotary tool holder 2 can also be made floating, and the steel wire has a certain rigidity to play a guiding role. The curved surface guides the tool 4 to drive the tool rest 2 to swing.

[0025] The cutter 4 can be an elastic blade, and the peeling surface, that is, the curved surface between the steel wire layers, guides the deformation of the cutter 4 .

[0026] The horizontal rotary table 10 is provided with a tire toe positioning ring 11 or a positioning stake and a tire shoulder positioning ring 9 or a positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com