Soft gel self-driving micro motor and preparation method thereof

A micro-motor, self-driven technology, applied in the direction of chemical instruments and methods, coatings, catalyst carriers, etc., can solve the problems of modification and improvement difficulties, complex manufacturing methods, small size of micro-motors, etc., to achieve good reusability, effective Conducive to functionalization and functional integration, good economic benefits and the effect of industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

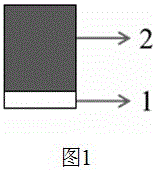

[0028] A preparation method of a soft gel self-driven micromotor, comprising the following steps:

[0029] (1) Take 1g of acrylamide monomer, disperse it in 4mL of water, pass nitrogen to remove oxygen, add 1mL of 0.25mg / mL N,N-methylenebisacrylamide aqueous solution, and add 3mg of potassium persulfate initiator And 20μL of N,N,N',N'-tetramethylethylenediamine catalyst, ultrasonically vibrate evenly. Then the gained solution is placed in a test tube with an internal diameter of 3 mm and a length of 150 mm and sealed, and placed at room temperature to react for 12 hours. After the reaction is completed, the hydrogel in the test tube is taken out, and a section of hydrogel (major diameter) of 3 mm in length is cut off. Ratio of 1), as a raw material for the manufacture of soft motors.

[0030] (2) The surface of the hydrogel obtained in step (1) is uniformly coated with high-vacuum silicone grease, and a circular bottom surface is left untreated, and this surface is used as a ...

Embodiment 2

[0033] A preparation method of a soft gel self-driven micromotor, comprising the following steps:

[0034] (1) Take 0.5g of acrylamide and 0.5g of acrylic acid monomer, disperse it in 4mL of water, and add 1mL of 0.25mg / mL N,N-methylenebisacrylamide aqueous solution, and add 3mg of supernatant Potassium sulfate initiator and 20 μL N,N,N',N'-tetramethylethylenediamine catalyst, ultrasonically oscillate evenly. Then the gained solution is placed in a test tube with an internal diameter of 3 mm and a length of 150 mm and sealed, and placed at room temperature to react for 12 hours. After the reaction is completed, the hydrogel in the test tube is taken out, and a section of hydrogel (major diameter) of 3 mm in length is cut off. Ratio of 1), as a raw material for the manufacture of soft motors.

[0035] (2) The surface of the hydrogel obtained in step (1) is uniformly coated with high-vacuum silicone grease, and a circular bottom surface is left untreated, and this surface is us...

Embodiment 3

[0038] A preparation method of a soft gel self-driven micromotor, comprising the following steps:

[0039](1) Take 0.75g of isopropylacrylamide monomer, disperse it in 3mL of water, and add 2mL of 0.25mg / mL N,N-methylenebisacrylamide Potassium sulfate initiator and 20 μL N,N,N',N'-tetramethylethylenediamine catalyst, ultrasonically oscillate evenly. Then the gained solution is placed in a test tube with an internal diameter of 3 mm and a length of 150 mm and sealed, and placed at room temperature to react for 12 hours. After the reaction is completed, the hydrogel in the test tube is taken out, and a section of hydrogel (major diameter) of 3 mm in length is cut off. Ratio of 1), as a raw material for the manufacture of soft motors.

[0040] (2) The surface of the hydrogel obtained in step (1) is uniformly coated with high-vacuum silicone grease, and a circular bottom surface is left untreated, and this surface is used as a catalyst loading surface.

[0041] (3) Place the tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com