Method for synthesizing cyclohexanone oxime under catalytic action of molecular sieve

A technology of cyclohexanone oxime and molecular sieve, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high hydroxylamine salt dosage and low selectivity, and achieve high selectivity of cyclohexanone oxime , high conversion rate, simple post-processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

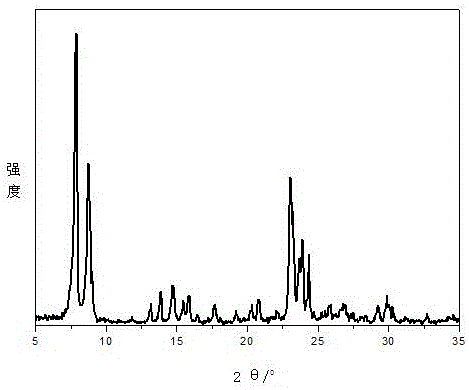

Image

Examples

Embodiment 1

[0024] The first step is according to weight ratio cyclohexanone: catalyst is 1:0.1, cyclohexanone: solvent is 1:5, cyclohexanone: the mol ratio of ammonia is 1:1.7, and ammonia is liquid ammonia, and concentration is 25%, solvent It is a mixture of 25% by weight of water and 75% of tert-butanol, and the catalyst is a molecular sieve with an MFI topology, a Si / Ti molar ratio of 60, a Si / B molar ratio of 100, and a Si / Al molar ratio of 100;

[0025] The second step reaction temperature is 75 DEG C, and the mol ratio of cyclohexanone: hydrogen peroxide is 1:1.1, and the concentration of hydrogen peroxide is 30%, and the dropping time is 1 hour, continues to react for 0.5 hour after dropping, and reacts The pressure of the system is 1 atm.

[0026] The analysis results showed that the conversion rate of cyclohexanone was 99.6%, and the selectivity of cyclohexanone oxime was 99.7%.

Embodiment 2

[0032] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0033] In the first step, according to the weight ratio cyclohexanone: catalyst is 1:0.05, cyclohexanone: solvent is 1:10, the catalyst has MFI topological structure, composition Si / Ti molar ratio is 40, Si / B molar ratio Be 120, the molecular sieve that Si / Al mol ratio is 200; In the second step, cyclohexanone: the mol ratio of hydrogen peroxide is 1:1.05.

[0034] The analysis results showed that the conversion rate of cyclohexanone was 99.5%, and the selectivity of cyclohexanone oxime was 99.7%.

Embodiment 3

[0036] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0037]In the first step, according to the weight ratio cyclohexanone: catalyst is 1:0.35, cyclohexanone: solvent is 1:3, cyclohexanone: the molar ratio of ammonia is 1:1.1, and the catalyst has MFI topological structure, composition Molecular sieves with a Si / Ti molar ratio of 60, a Si / B molar ratio of 60, and a Si / Al molar ratio of 80; in the second step, the reaction temperature is 85°C and the cyclohexanone:hydrogen peroxide molar ratio is 1 : 1.3, the dropping time was 2 hours, and continued to react for 1 hour after the dropwise addition was completed.

[0038] The analysis results showed that the conversion rate of cyclohexanone was 99.0%, and the selectivity of cyclohexanone oxime was 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com