A kind of translucent magic heat transfer film and preparation method thereof

A heat transfer, translucent technology, applied in vacuum evaporation coating, coating, sputtering coating and other directions, can solve the problems of high cost, complex production process, unstable magic effect, etc., to improve the effect of anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

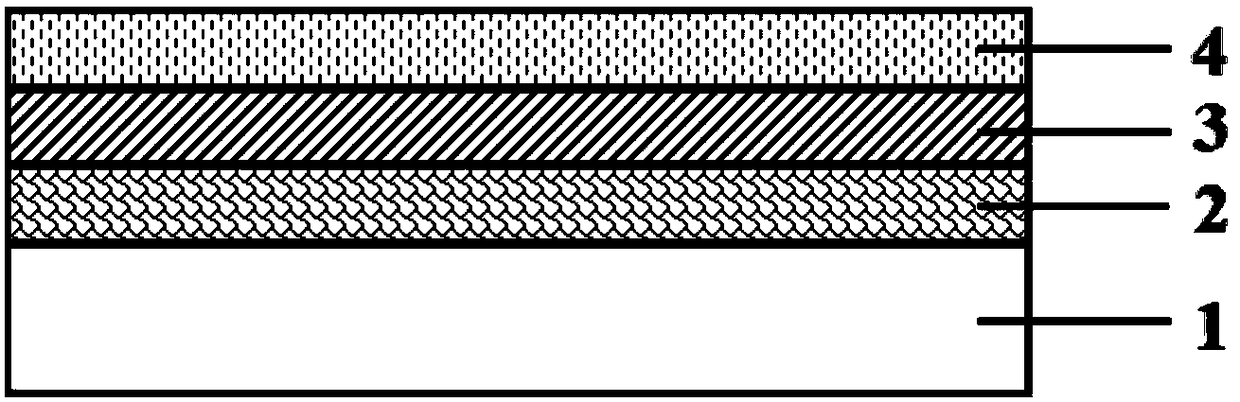

Image

Examples

Embodiment 1

[0026] Embodiment 1 of a preparation method of a translucent illusion heat transfer film: a preparation method of a translucent illusion heat transfer film, the preparation steps are as follows

[0027] 1) Use biaxially stretched polyester film as the base film, hereinafter referred to as PET base film;

[0028] 2) Coating the surface of the biaxially stretched polyester film to form a release layer: first mix and stir 45% distilled water and 45% methanol, the stirring rate is 800r / min, and the stirring time is 10min. Add 10% modified cellulose and stir for 8 minutes to obtain the release layer feed solution. Introduce the release layer material liquid into the trough of the coating machine, and coat a layer of uniform coating on the surface of the polyester film with the anilox roller belt material, scraper, rubber roller, etc., and then react and dry in a high-temperature oven , to form a release layer; the existence of the release layer can separate other coatings from the...

Embodiment 2

[0032] Embodiment 2 of a preparation method of a translucent magic color heat transfer film: a preparation method of a translucent magic color heat transfer film, the preparation steps are as follows

[0033] 1) Use biaxially stretched polyester film as the base film, hereinafter referred to as PET base film;

[0034] 2) Coating the surface of the biaxially stretched polyester film to form a release layer: first mix and stir 50% distilled water and 45% methanol, the stirring rate is 900r / min, and the stirring time is 15min. Add 5% modified cellulose and stir for 5 minutes to obtain the release layer feed solution. Introduce the release layer material liquid into the trough of the coating machine, and coat a layer of uniform coating on the surface of the polyester film with the anilox roller belt material, scraper, rubber roller, etc., and then react and dry in a high-temperature oven , to form a release layer; the existence of the release layer can separate other coatings fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com